Method for producing fabrics by weaving terylene and natural fibers or regenerated fiber yarns

A technology of natural fibers and regenerated fibers, applied in the direction of fabrics, textiles, dyeing methods, etc., can solve the problems of low production efficiency and cost of printing and dyeing cloth, restrictions on pattern change, etc., and achieve the effects of low production cost, low production cost and long time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

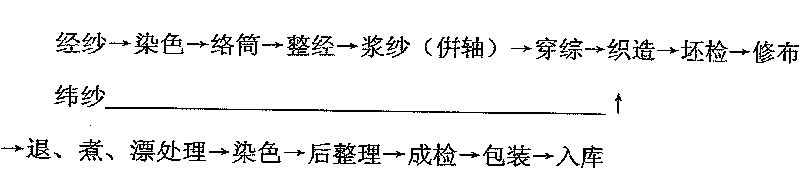

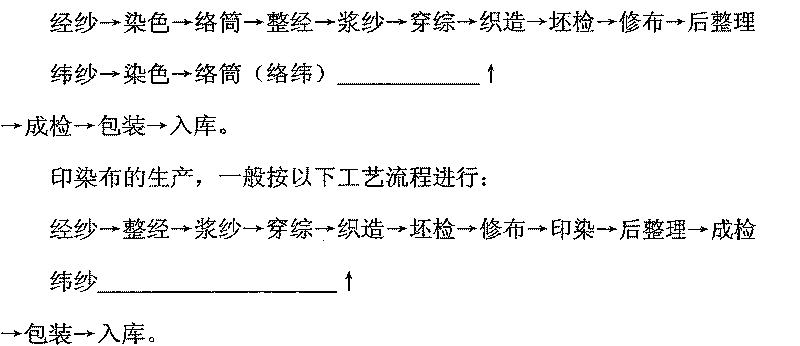

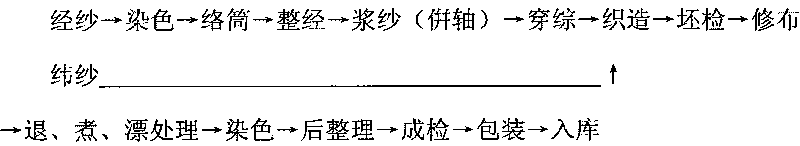

[0022] see figure 1 , figure 1 It is a production process flow chart of the production method of the fabric interwoven with polyester and natural fiber or regenerated fiber yarn of the present invention. Depend on figure 1 It can be seen that the production method of the fabric interwoven with polyester and natural fibers or regenerated fiber yarns of the present invention, the method comprises the following processes:

[0023] Step 1, select polyester as the warp raw material, select natural fiber yarn or regenerated fiber yarn as the weft raw material, dye the warp yarn with disperse dyes, and then make bobbins;

[0024] Step 2, warping and sizing or winding the warp yarns on the weaving beams, and weaving them with the weft yarns to form gray fabrics. When weaving gray fabrics, the weft yarns do not need to be dyed, and the gray yarns are directly used for weaving;

[0025] Step 3, dyeing or bleaching the woven gray cloth, dyeing adopts rope dyeing, jigger dyeing or p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com