Natural-color straw pulp with improved tearing index, freeness and tensile index, and stable performance

A technology of tear index and tensile index, applied in the application of paper products, in the field of mixed pulp, can solve the problems of large fluctuations in pulp quality, low tear index and tensile index, straw pulp cannot have stable performance, etc. , to achieve the effect of stable slurry data and small fluctuations in slurry quality

Active Publication Date: 2010-04-07

SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

View PDF7 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The relationship between beating degree and pulp fiber composition and fracture length, "Paper and Papermaking" No. 03, 2004 This paper analyzes the influence of the same or different beating degree values on the pulp fiber composition and fracture length, and the detection method of beating degree The sum of the data and its function is far less effective than the detection method and data of the sieve fraction percentage of the pulp fiber composition and its function, and it is not as effective as the detection method and data of the fracture length and its function

[0017] In summary, straw pulp has the disadvantages of low freeness, low tear index and tensile index, and large fluctuations in pulp quality; at the same time, bleaching and beating have obvious effects on the physical and chemical properties of straw pulp, resulting in the inability of straw pulp. stable performance

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1-6

[0073] Embodiment 1-6 adopts ammonium sulfite method cooking

[0074] Table 11. Ammonium sulfite cooking parameters

[0075] Example

[0076] Example

Embodiment 7-13

[0077] Embodiment 7-13 adopts caustic soda-anthraquinone method cooking

[0078] Table 12. Caustic soda-anthraquinone cooking parameters

[0079] Example

Embodiment 14-21

[0080] Embodiment 14-21 adopts kraft cooking

[0081] Table 13. Kraft Cooking Parameters

[0082]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| free rate | aaaaa | aaaaa |

| free rate | aaaaa | aaaaa |

| free rate | aaaaa | aaaaa |

Login to View More

Abstract

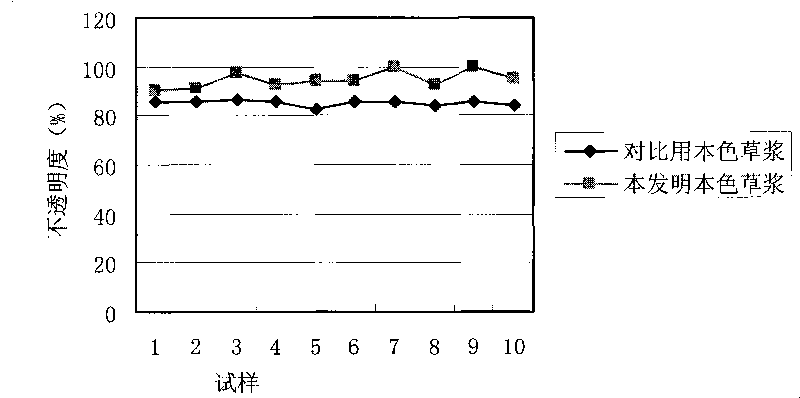

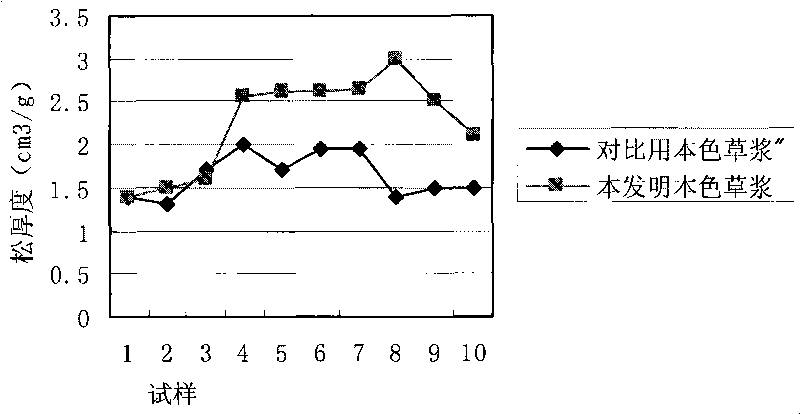

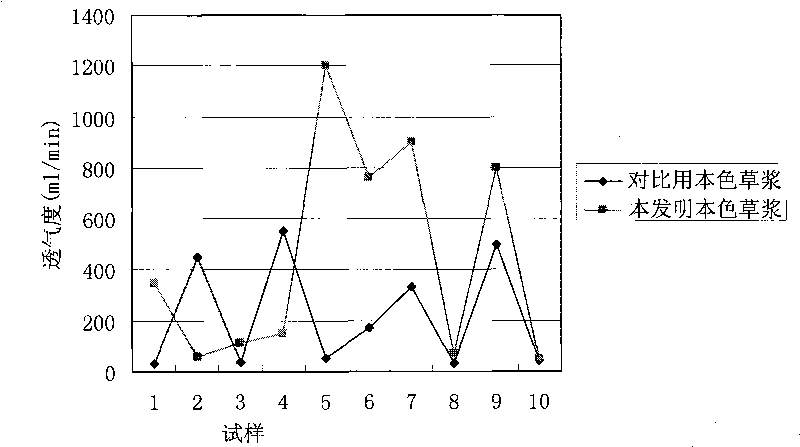

The invention relates to natural-color straw pulp with improved tearing index, freeness and folding strength, and stable performance, in particular to natural-color straw pulp and application thereof in mixed pulp and paper products. The straw pulp has the advantages that: color phase or whiteness of the straw pulp is remarkably improved; the bulk and air permeability are high; and the acquired data of the sizing agent of the natural-color straw pulp is more stable because of small quality fluctuation of sizing agent.

Description

technical field [0001] The present invention relates to a kind of natural color straw pulp with improved tear index, freeness and tensile index and stable performance. Specifically, the present invention relates to a kind of said natural color straw pulp and their mixed pulp , Application in paper products. Background technique [0002] In daily life, paper can be divided into cultural paper, industrial paper, household paper and special paper according to its use, among which cultural paper can be simply divided into uncoated paper and coated paper. Uncoated paper is called uncoated paper, such as newsprint, offset paper, electrostatic copy paper and writing paper, etc.; coated paper is called coated paper, such as coated paper, calendar paper, Glossy paper, glass cardboard, etc. Their manufacture includes the following steps: [0003] Pulping section: raw material selection→cooking and separating fibers→washing→bleaching→washing and screening→concentrating or copying in...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): D21H11/12

Inventor 毕衍金李洪法宋明信杨吉慧王建民徐金香

Owner SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com