Composite paper board and production method thereof

A production method and cardboard technology, which is applied in the field of food packaging bags, can solve the problems of excessive glue consumption, easy cracking, and brittleness of composite cardboard, and achieve the effect of simple and easy production method, not easy to crack, and environmentally friendly cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

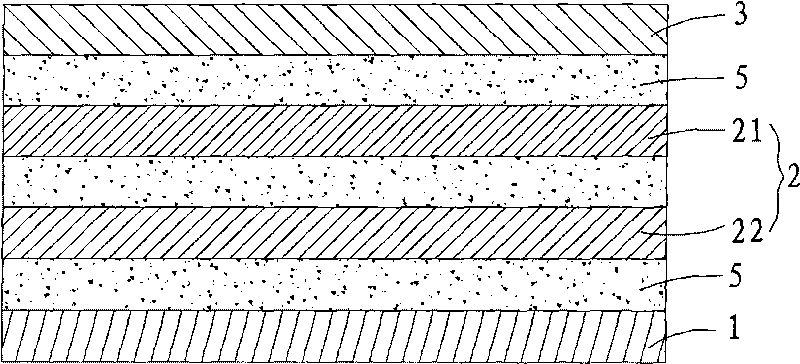

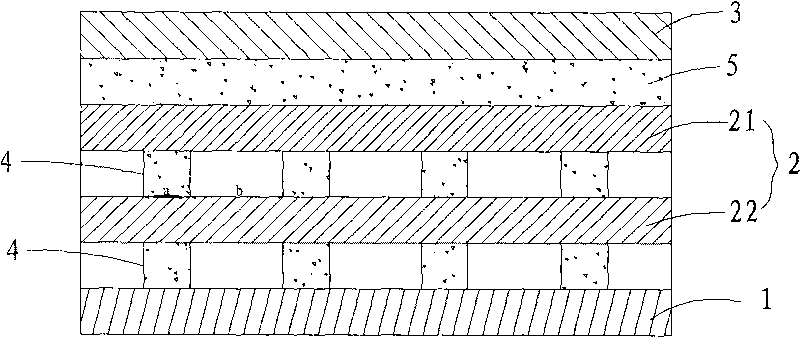

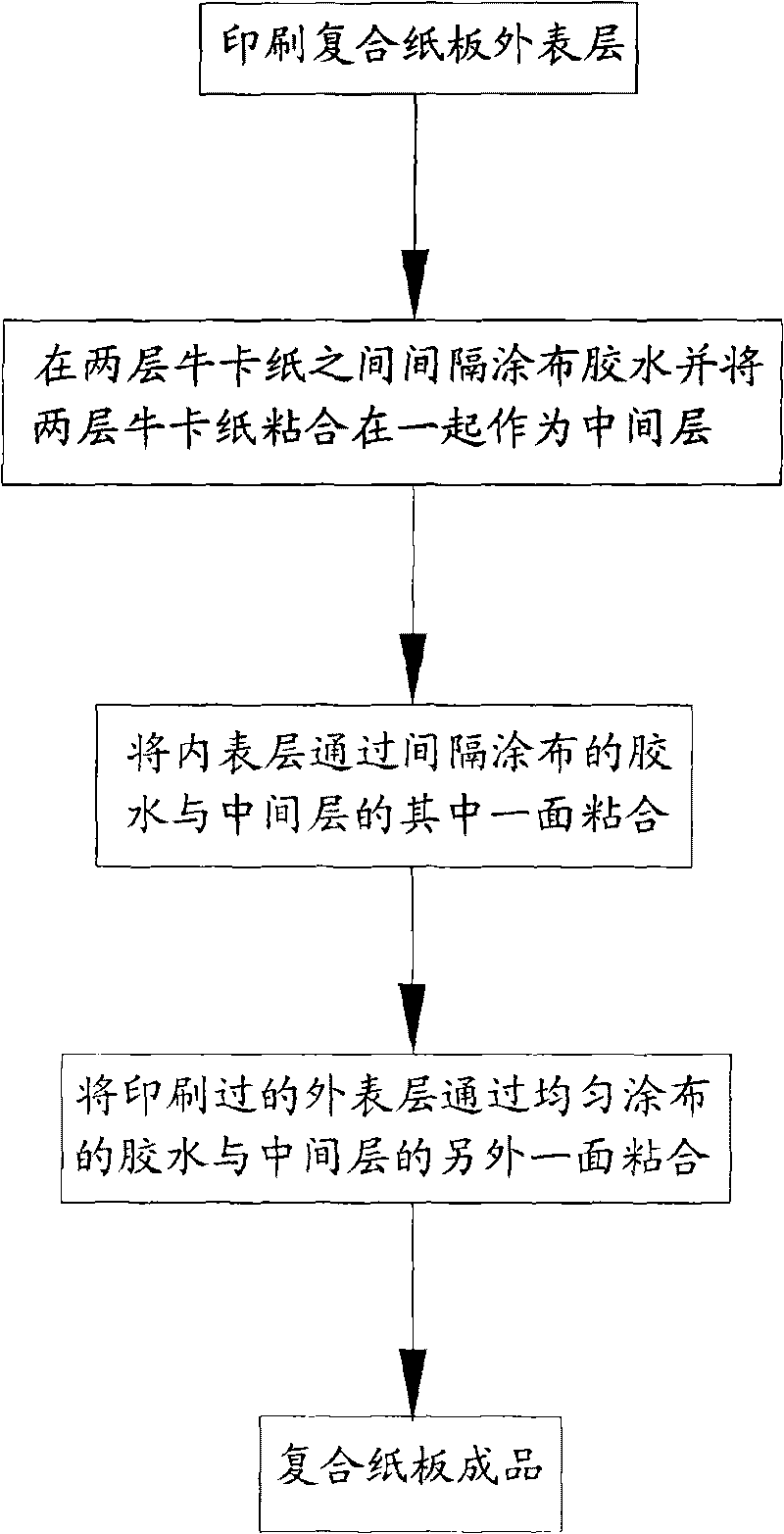

[0026] figure 2 Shown is a structural schematic diagram of the present invention, a composite cardboard, including an intermediate layer 2 and inner and outer layers 1, 3, wherein the intermediate layer 2 is formed by bonding two layers of kraft cardboard 21, 22 with glue 4 coated at intervals , the outer surface layer 3 is pasted on one side of the middle layer 2 through uniformly coated glue 5 , and the inner surface layer 1 is pasted on the other side of the middle layer 2 through glue 4 coated at intervals.

[0027] In this embodiment, the glue 4 coated at intervals is kept parallel, and the ratio of the width a of the glue 4 coated at intervals to the width b of the gap is 1:2. Of course, the glue 4 can also be applied at intervals of other forms. The ratio of a to b is also not limited thereto.

[0028] Between the two layers of kraft cardboard 21, 22 and between the kraft cardboard 22 and the inner surface layer 1, the glue 4 is coated at intervals, so that the prepar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com