Reinforced concrete structure or steel-concrete combined structure system

A reinforced concrete and composite structure technology, applied in the direction of building structure, construction, etc., can solve the problems of increasing structural weight and rigidity, increasing earthquake action, hidden safety hazards, etc., to achieve the protection of people's life and property safety, strong energy consumption capacity of the structure, Reasonable effect of force transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

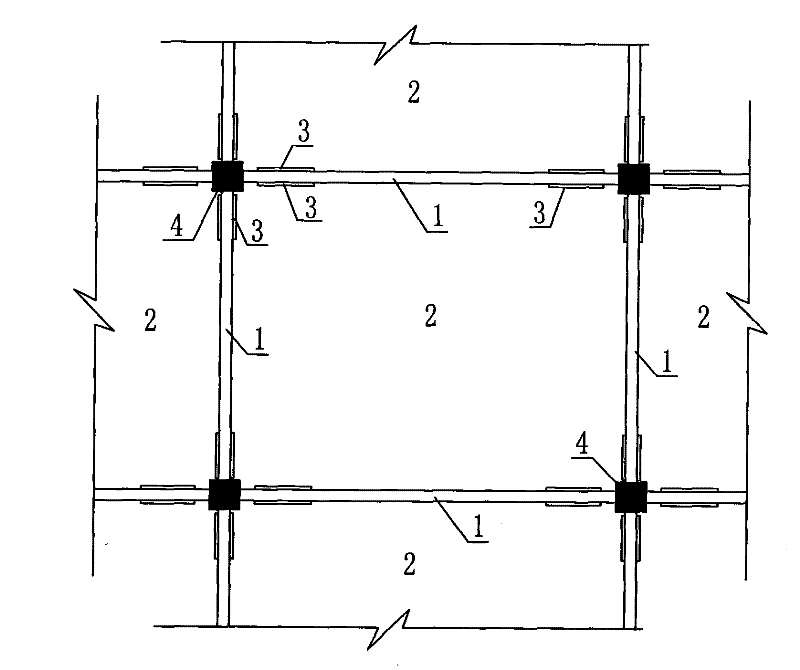

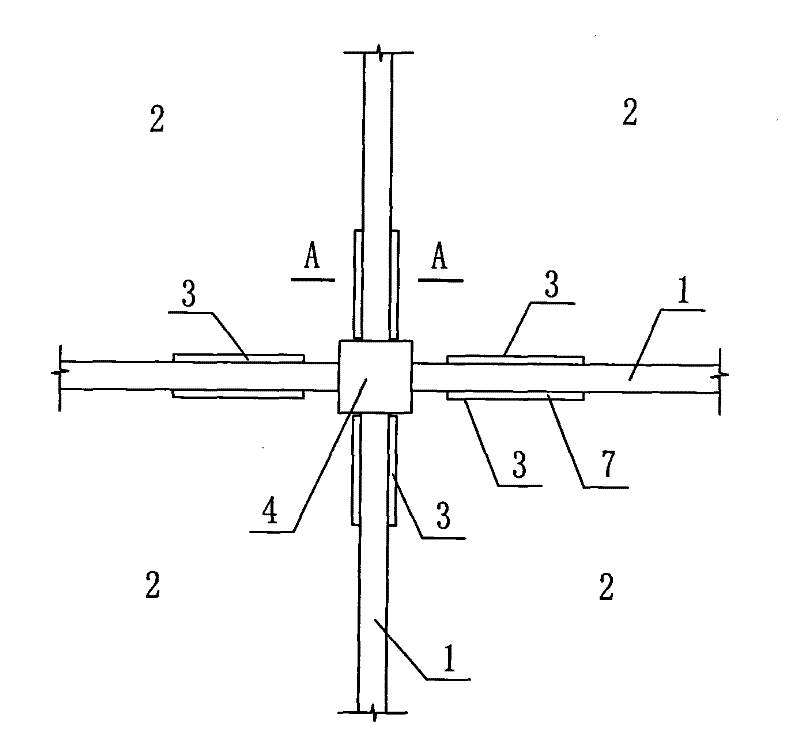

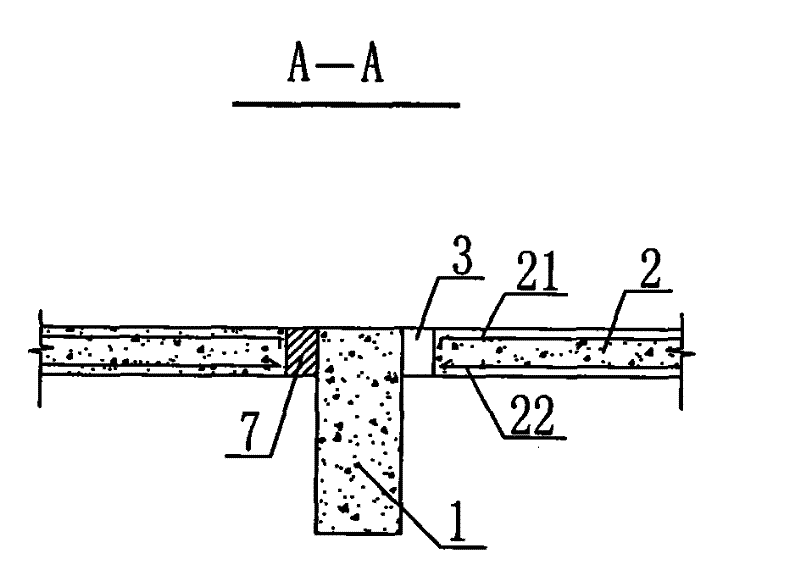

[0027] Such as Figure 1 to Figure 3 As shown, it is a schematic diagram of the structure of the present invention applied to the reinforced concrete frame structure system. At the near connection node of the beam 1 and the column 4, a rectangular opening 2 is opened on both sides of the beam 1, and the rectangular opening 2 is 5 away from the column. The side is 0-300mm, the width of the rectangular opening 2 is preferably 50-100mm, and the length is about L / 6 (L is the span of the beam), and it is greater than 300mm. 3, that is, there is no stressed reinforcement in floor 2. And the flexible material 7 is filled in the rectangular hole 3, and the flexible material 7 plays the role of waterproof and sound insulation.

[0028] Since the stress on the floor 2 is generally not large, most of them are structural reinforcements. After the rectangular opening 3 is set, the bearing capacity of the floor 2 can be realized by strengthening the reinforcement of other parts. After the...

Embodiment 2

[0030] Such as Figure 4 As shown, it is a schematic diagram of the structure of the present invention applied in the frame-shear wall structure system, which is at the connection node between the beam 1 and the column 4, and the connection between the beam 1 and the shear wall 5, on both sides of the beam 1 Rectangular hole 3 is all established, and all the other are with embodiment 1.

Embodiment 3

[0032] Such as Figure 5 As shown, it is a schematic diagram of the structure of the present invention applied in the shear wall structure system. At the joint between the shear wall 5 and the beam 1, rectangular openings 3 are set on both sides of the beam 1, and the rest are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com