Method for facility TanTsing (first procedure of tea processing, by laying fresh tea on winnowing forks or ground to lose moisture and get rid of the smell of grass in the tea) of tea leaves

A facility and tea technology, applied in the field of facility spreading of tea, can solve the problems of restricting gas exchange, limited amount of fresh leaves spreading, affecting the quality of spreading green leaves, etc., to achieve the effect of promoting beneficial transformation and improving material basis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

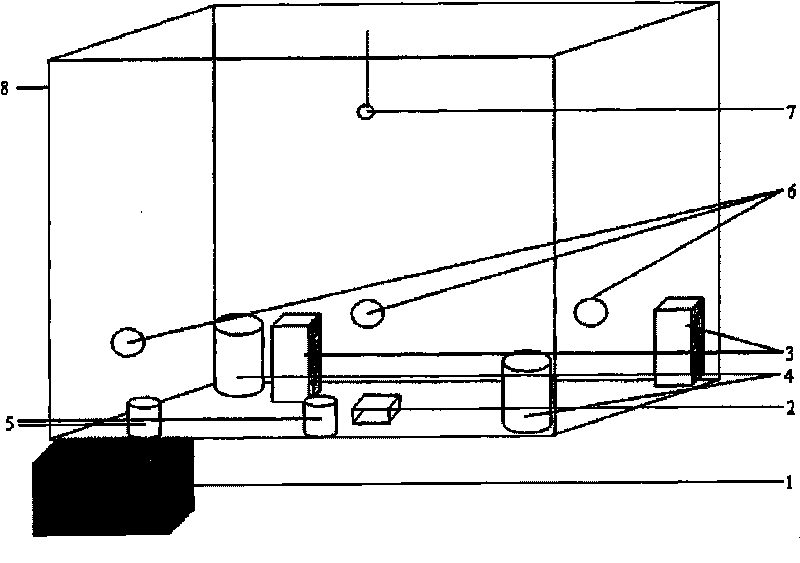

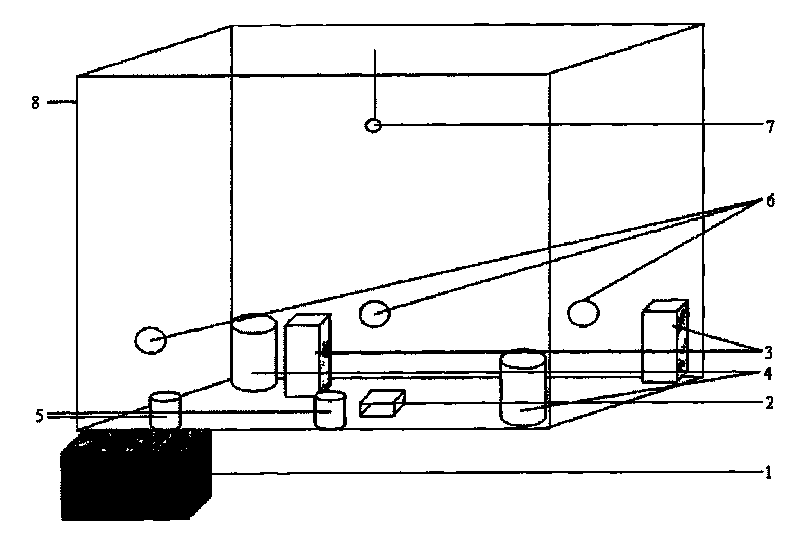

[0015] see figure 1 , the present invention is mainly composed of specific equipment in the spreading room 8 and its supporting process, the equipment includes: an electric control cabinet 1, a multi-layer spreading rack 2 (published by the patent number ZL200820082983.8), an air conditioner 3, a dehumidifier 4, The ultrasonic atomizer 5, the ventilation fan 6, the temperature and humidity probe 7, the air conditioner 3, the dehumidifier 4 and the ultrasonic atomizer 5 are used to control the humidity in the blue room 8, and the ventilation fan 6 is placed below, which can help to adjust the environment Gas, the electric control cabinet 1 is connected with the temperature and humidity probe 7, the air conditioner 3, the dehumidifier 4, the ultrasonic atomizer 5, and the ventilation fan 6. The electric control cabinet 1 can display the temperature and humidity parameters of the environment, and the air conditioner 3, the air conditioner can be controlled by setting. The operati...

Embodiment 2

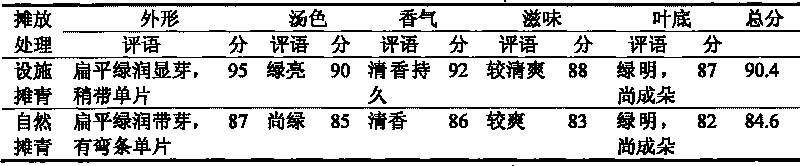

[0020] After the same fresh leaf raw materials were spread for 8 hours in two ways: natural greening and facility greening respectively, the same processing procedure was used to make flat tea. The sensory evaluation comparison is shown in Table 1. It can be seen from Table 1 that the use of facility spread green treatment can help to improve the aroma and taste of finished tea.

[0021] Table 1 Sensory comparison of finished tea processed by two spreading methods

[0022]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com