Plant curtain wall and method for manufacturing same

A plant and curtain wall technology, applied in the field of plant curtain walls, can solve the problems of uneven surface, falling and hurting people, and heavy, etc., and achieve the effect of rich and variable combination and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

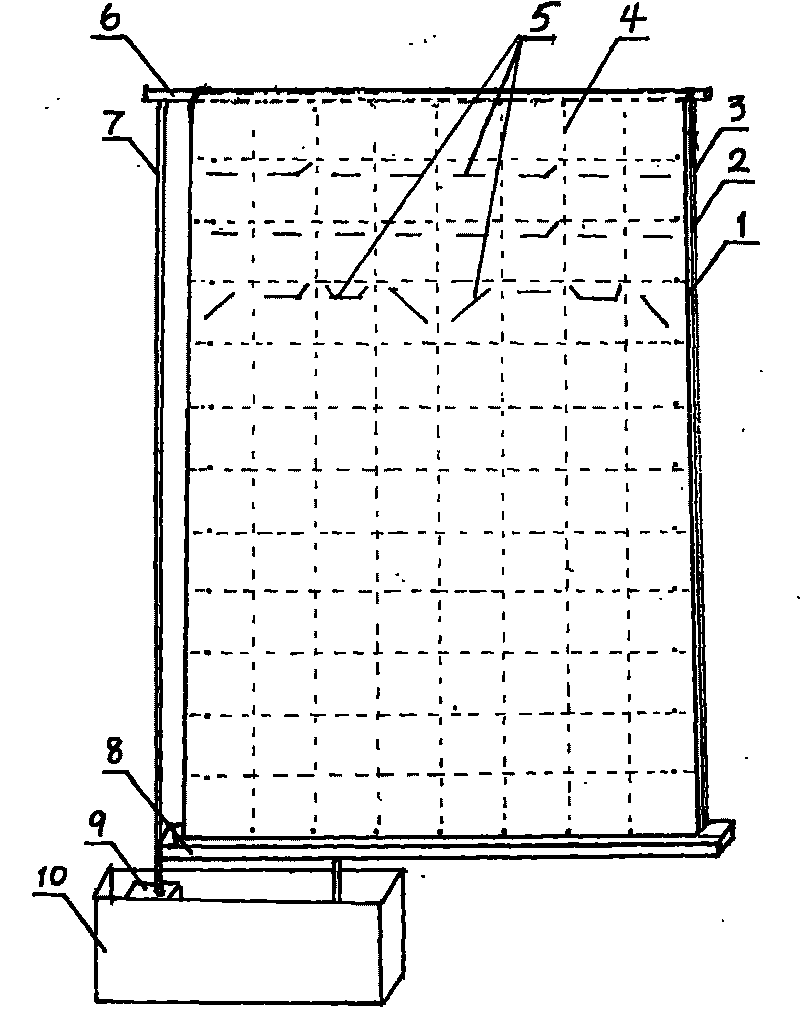

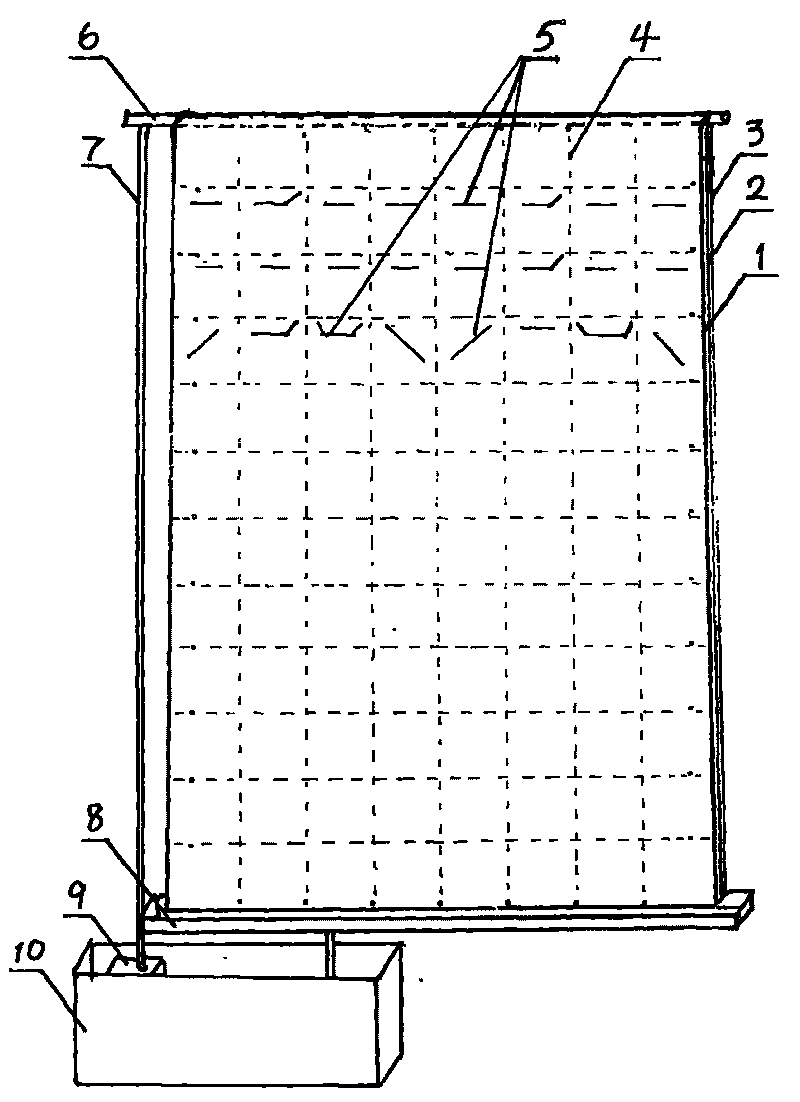

[0021] The present invention is described in further detail below in conjunction with the embodiments and with reference to the accompanying drawings: because the matrix cloth is the key material, it is specially made in detail as follows, it is mainly used for plant substrates for plane vertical soilless cultivation against walls or walls, or as The planting substrate of three-dimensional plastic (sculpture) soilless cultivation plants in scenic spots will have specific requirements in specific application environments. If it is beneficial to plant growth, the substrate cloth is required to have good air permeability and water absorption, and strong capillary action. The selection of the composition of layer 1 and core layer 2, the selection of thickness and specifications, and the selection of water-absorbent fillers are very important. In order to improve the mechanical strength and service life, the raw material of the matrix cloth is made of chemical fiber, because it is n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specification | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Specification | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com