Dry-type superfine powder magnetic separator

A technology of ultra-fine powder and magnetic separator, which is applied in the direction of magnetic separation, solid separation, chemical instruments and methods, etc., and can solve the problems that ultra-fine powder is easy to agglomerate and magnetic impurities cannot be separated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

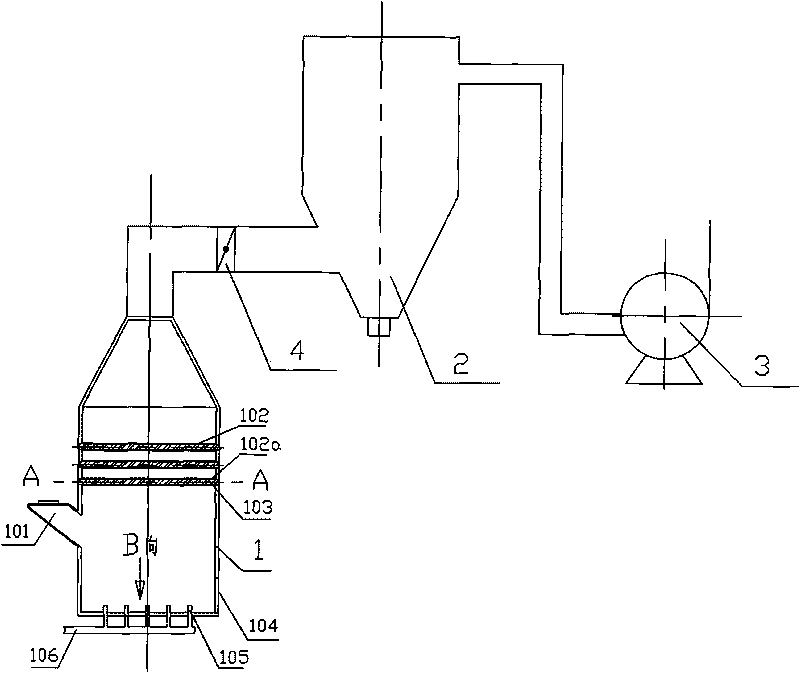

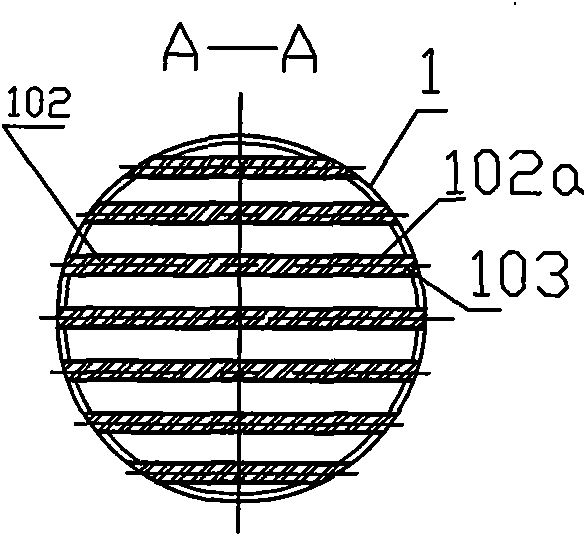

[0013] like figure 1 Shown is a schematic diagram of the structure of the present invention, which is composed of a cylindrical magnetic separation bin 1, a bag filter 2 and an induced draft fan 3 sequentially connected through pipelines. The side wall of the magnetic separation bin is provided with a feeding port 101, and the bottom is provided with a waste outlet. 104. A discharge port is provided on the top to connect with the bag dust collector 2, and a manual butterfly valve 4 is provided between the magnetic separation bin 1 and the dust collector.

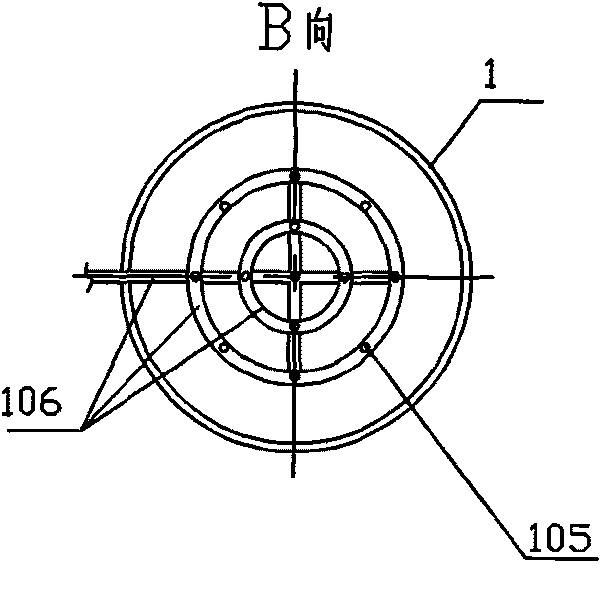

[0014] combine figure 1 , image 3 , the bottom of the magnetic separation chamber is provided with a group of compressed air nozzles 105, specifically the bottom is provided with an air inlet pipe 106 connected to the air compressor, the air inlet pipe 106 is divided into two parts: a straight pipe part and an inner and outer ring pipe, and the inner ring pipe is provided with 4 compressed air nozzles, 8 compressed air no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com