Side transducer for detecting rolling pressure of rolling mill

A force measuring sensor and rolling pressure technology, applied in the control field of rolling mills, can solve the problems of high shear strength, large shrinkage rate, poor impact resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

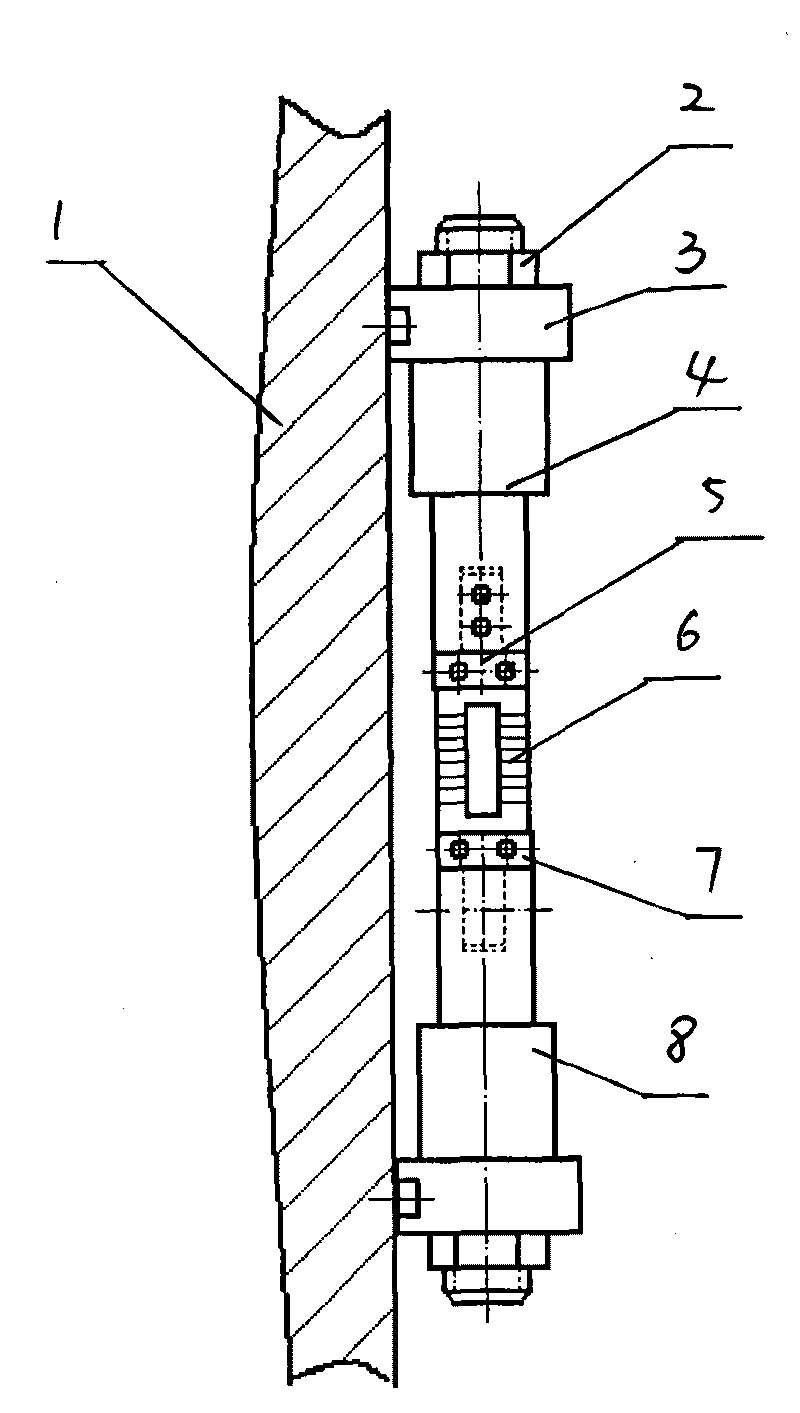

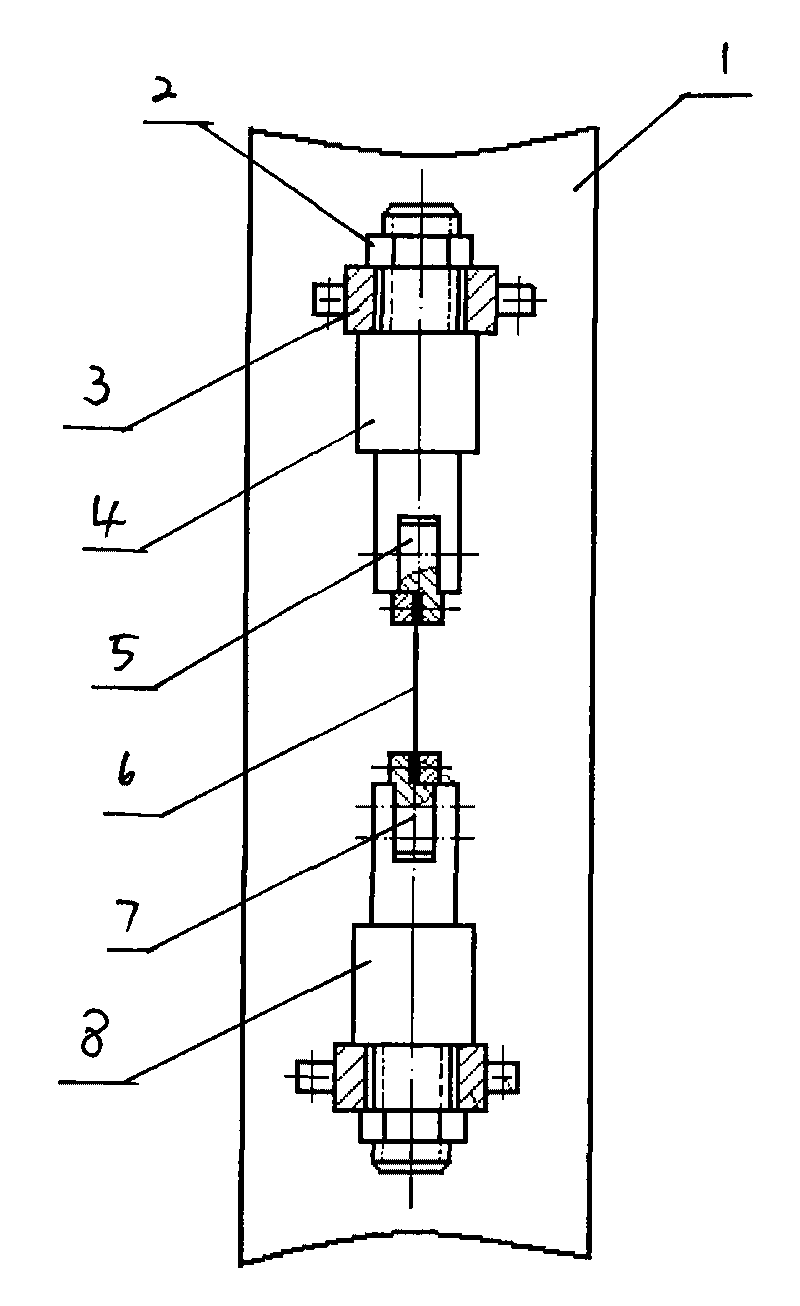

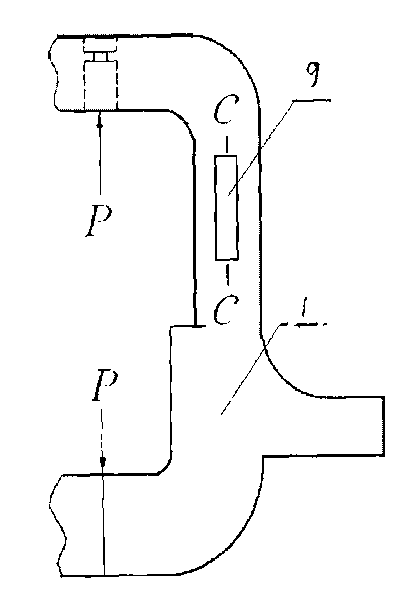

[0015] A side-mounted sensor 9 for detecting the rolling pressure of a rolling mill. A load cell 6 is arranged on the side of the frame column 1. The load cell 6 is vertically arranged along the center line of the frame column. The load cell 6 is determined by the thickness It is made of permalloy sheet of 0.3-0.6mm, and the permalloy sheet is vertically arranged with the frame column 1. There is a strip hole in the middle of the permalloy sheet, and the excitation coil N is wound on both sides of the strip hole. 1 and measuring coil N 2 , the two ends of the load cell are provided with upper and lower clamping heads 5,7, an insulating rubber pad is provided between the load cell 6 and the upper and lower clamping heads 5,7, and the upper and lower clamping heads 5,7 The upper and lower force transmission rods 4 and 8 are fixed by bolts, the upper and lower force transmission rods 4 and 8 respectively pass through the support 3 installed on the frame, and load cells are instal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Number of turns | aaaaa | aaaaa |

| Number of turns | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com