Parrot mouth shaped pendulous pre-twisted wire forming equipment and forming method thereof

A technology of forming equipment and pre-twisted wire, which is applied in the field of forming equipment and its forming process, can solve problems such as inconvenient installation, deformation of pre-twisted wire, and corona, and achieve high production efficiency, small footprint, and avoidance of corona Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

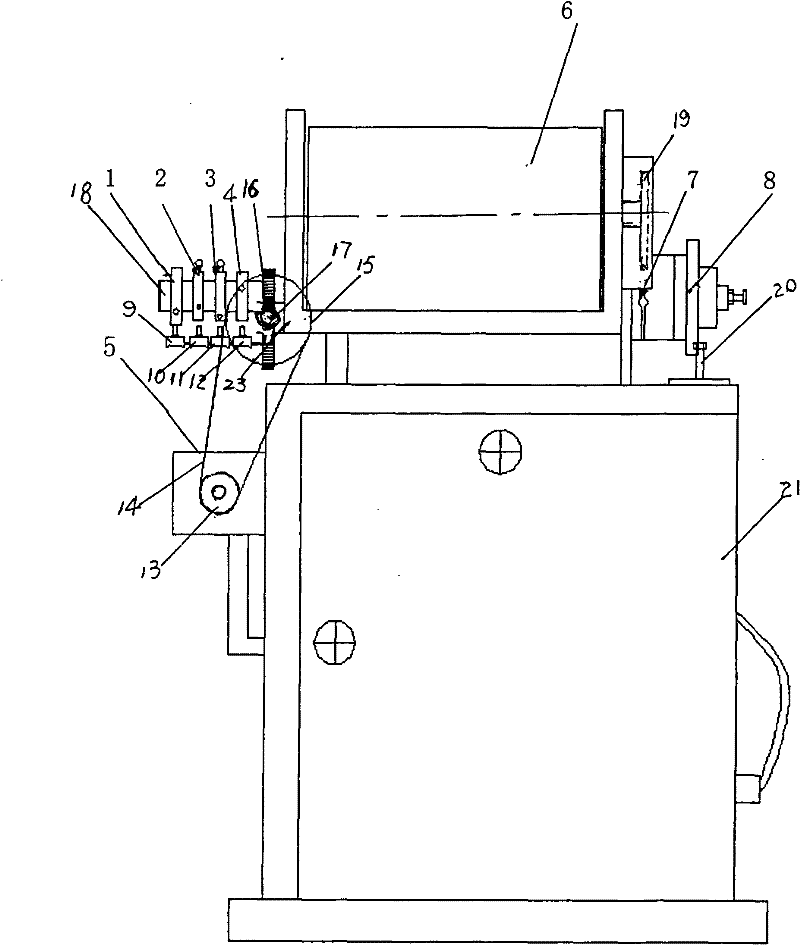

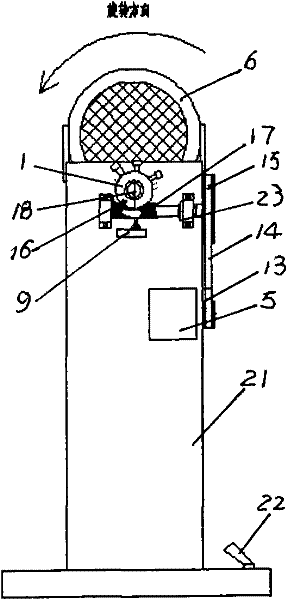

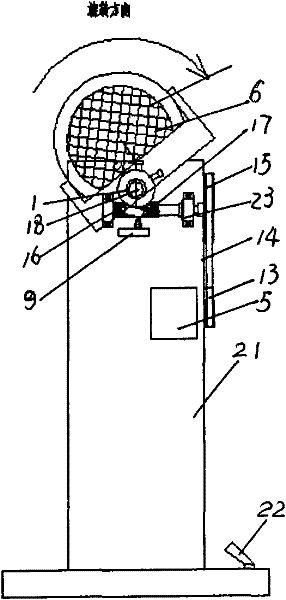

[0020] Refer to attached Figure 1~5 , a parrot beak-shaped hanging pre-twisted wire forming equipment includes a chassis 21, a main motor 5, a worm wheel 16, a worm 17, a cutting motor 6, a contact switch, a control cam, a guide rail groove 7, a tightening wheel 8, a bracket 20 and feet Step switch 22; Worm gear 16, worm screw 17 are installed on cabinet 21 side tops by mounting bracket 23, and four control cams are housed on the worm gear shaft 18, are respectively the first control cam 1, the second control cam 2, the third Control cam 3, the fourth control cam 4; four contact switches are installed at the lower part of the control cam, respectively the first contact switch 9 (main motor switch), the second contact switch 10 (cutting motor switch), the third One contact switch 11 (return switch), the fourth contact switch 12 (parking switch), four control cams correspond to four contact switches respectively; the main motor 5 is installed on the cabinet 21 side, and the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com