Side braking ratchet wheel tension compensation device of electrization railway

A technology for electrified railways and brake ratchets, which is applied in the field of compensation devices for compensating the anchor tension of catenary cables and contact wires, and side brake ratchet tension compensation devices. The effect of avoiding locomotive interruption and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

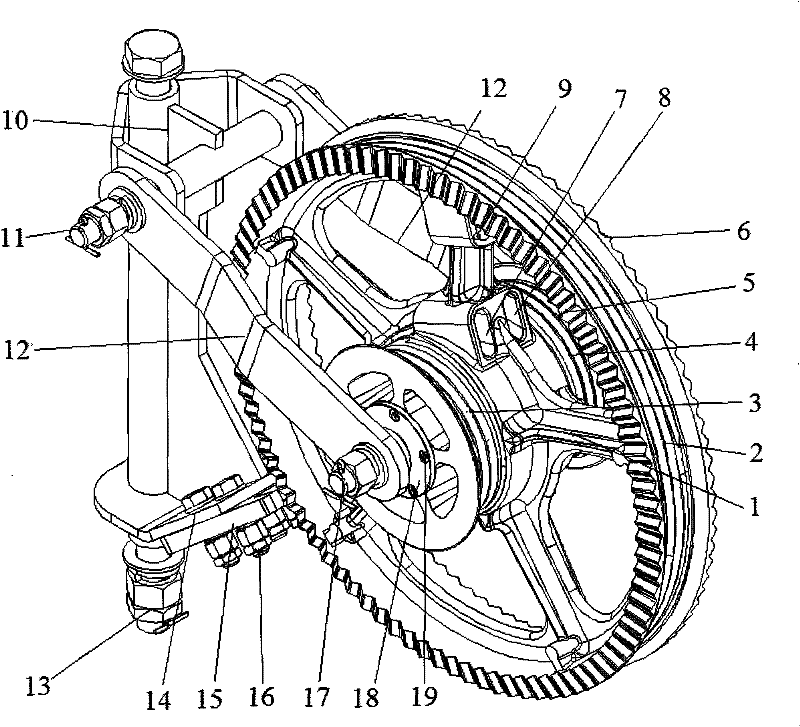

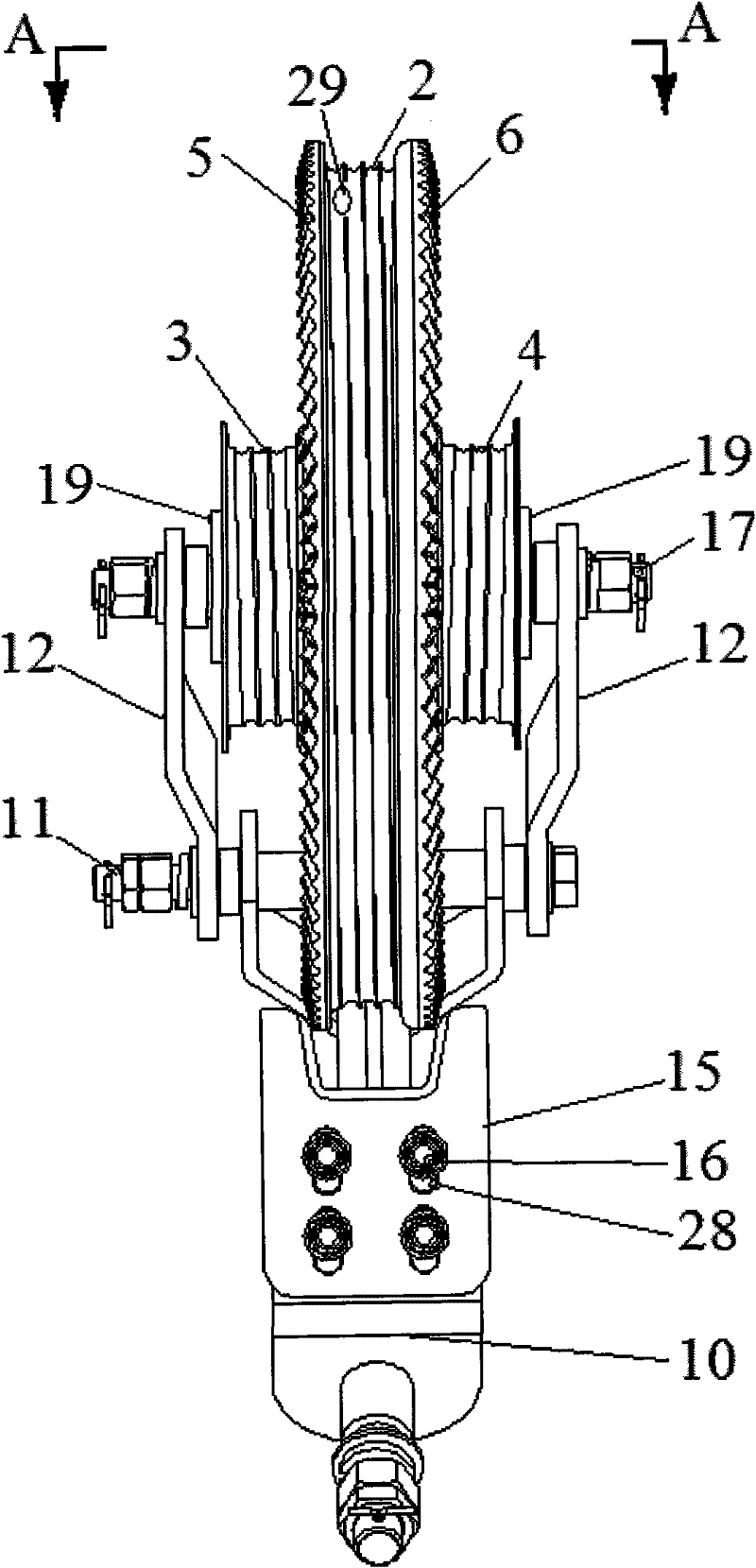

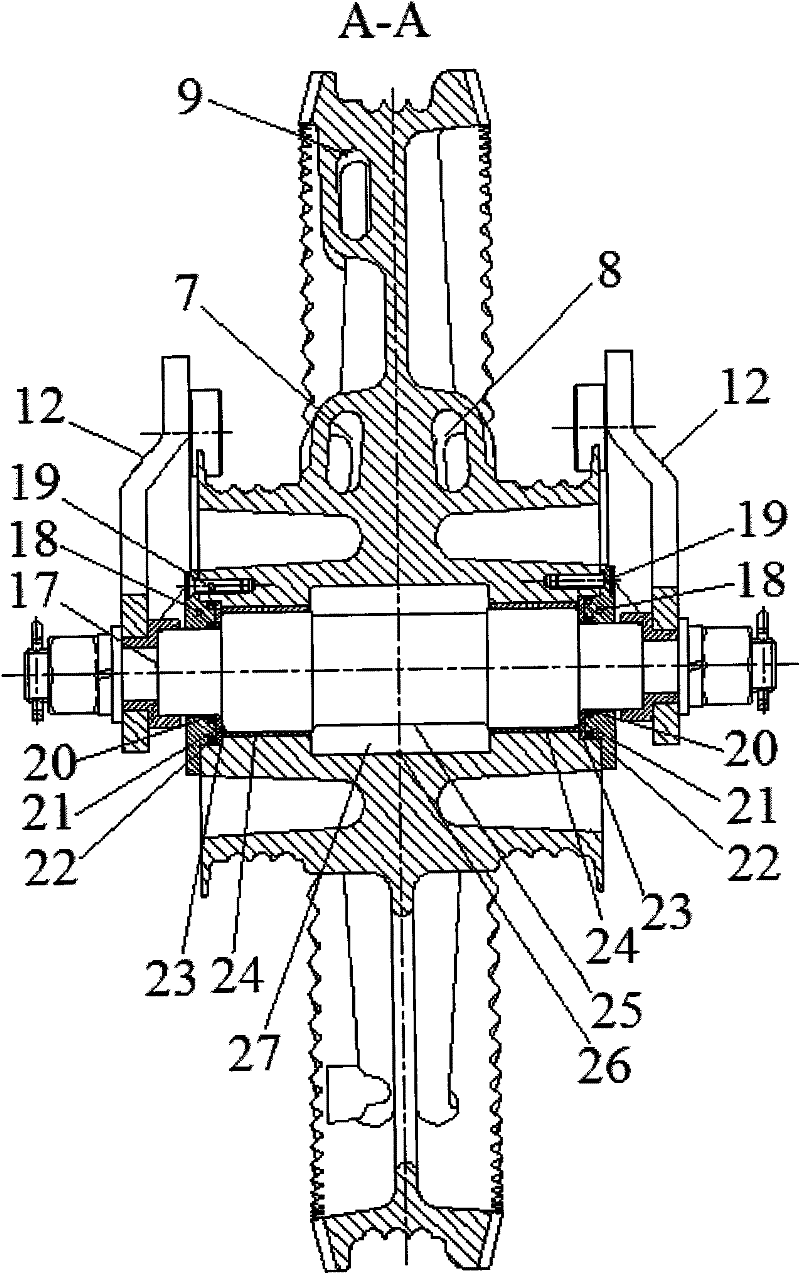

[0023] The structure of the side brake ratchet compensation device of the present invention, such as figure 1 , figure 2 , image 3 shown. Including a vertically arranged brake support frame 10, a bolt part A11 is arranged in the horizontal casing at the upper end of the brake support frame 10, and the bolts in the bolt part A11 pass through the horizontal casing, and the bolts are connected to one end of the two swing arms 12 respectively. The two swing arms 12 are respectively located at the two ends of the horizontal sleeve, and the other ends of the two swing arms 12 are respectively connected with the ratchet shaft 17. The ratchet shaft 17 is fixedly connected with the ratchet body 1, and the ratchet body 1 consists of a hub, a plurality of Composed of a spoke plate and a wheel rim, the two sides of the spoke plate of the ratchet bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com