Operation method of rubber block crushing system of waste truck tire outer tire crushing robot

An operation method and technology of a crushing system, which can be used in assembly machines, mechanical material recycling, plastic recycling, etc., can solve problems such as unbreakable and easily damaged blades, and achieve the effect of extending service life and improving working conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

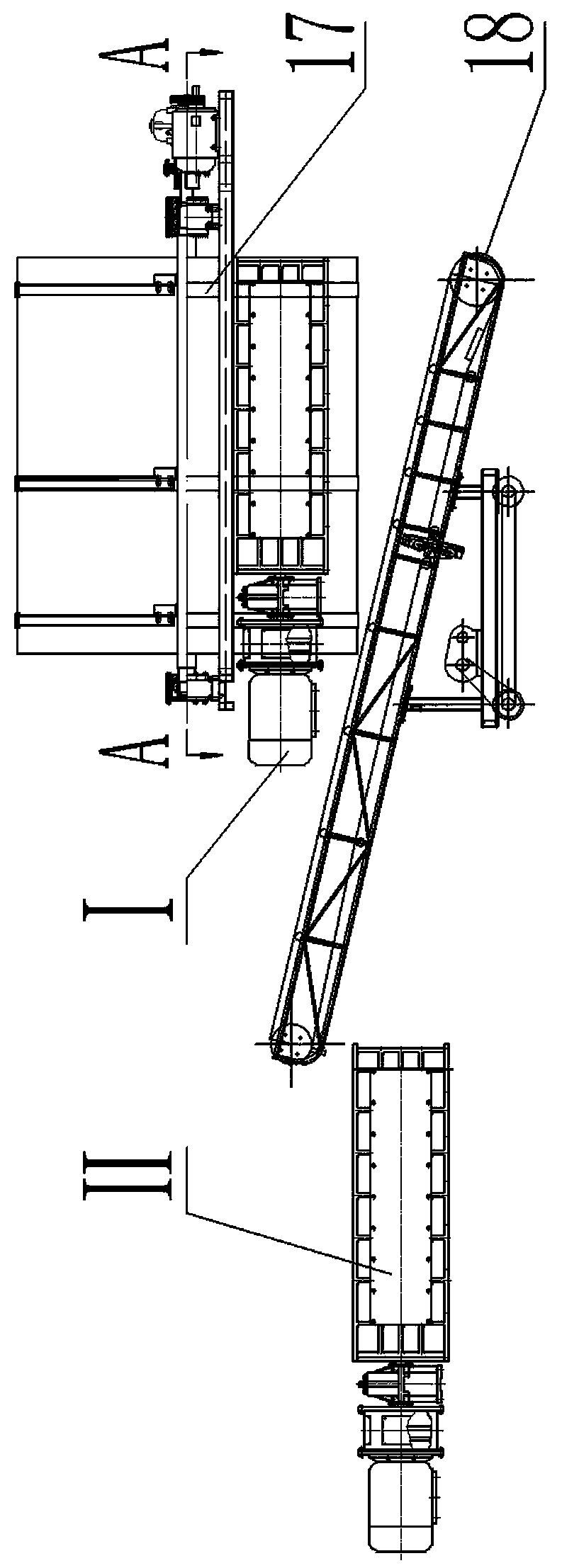

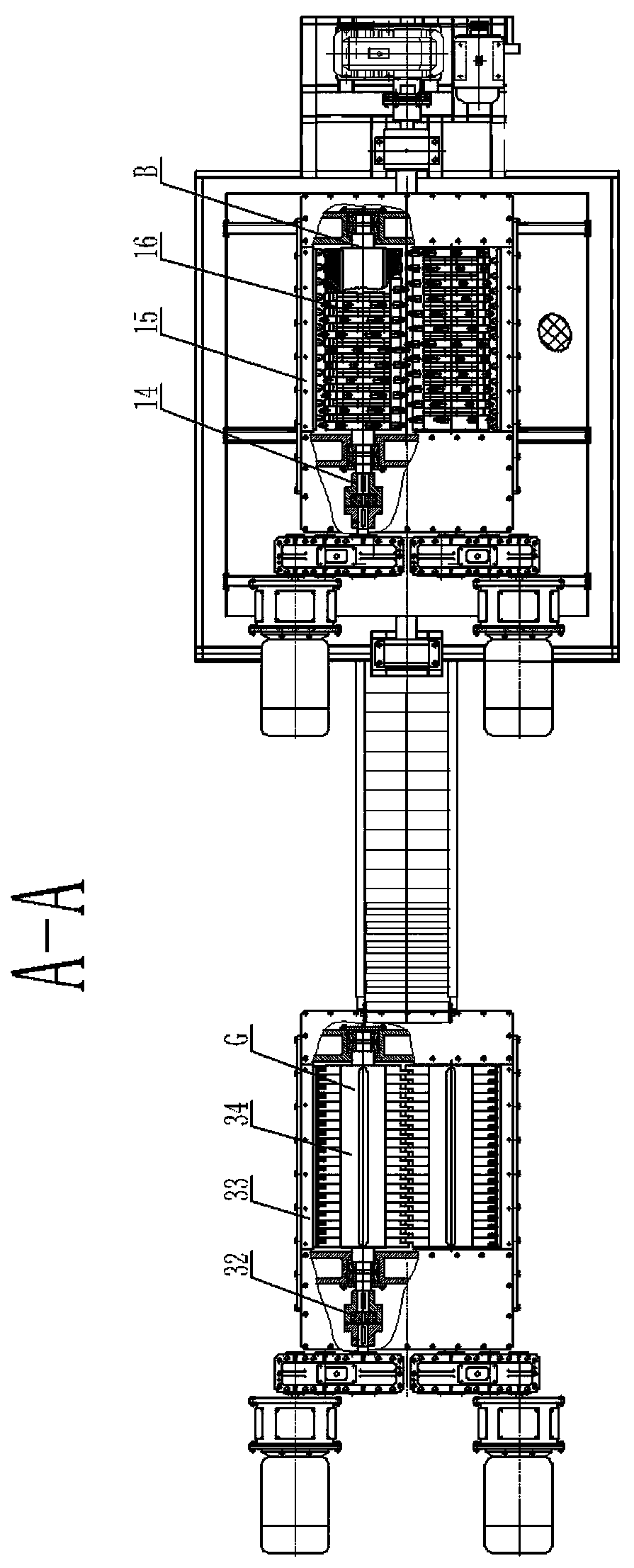

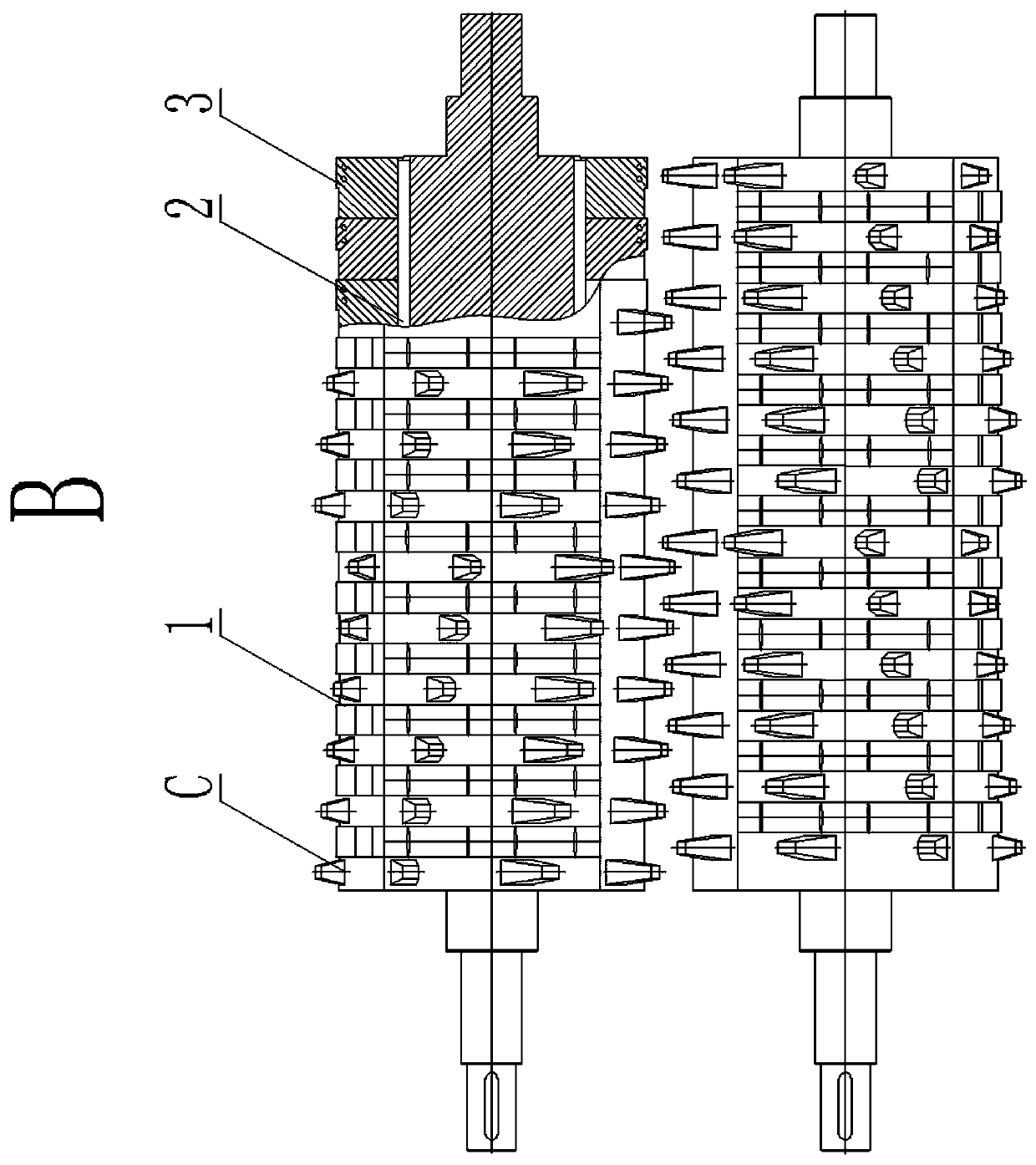

[0041] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 As shown, the operation method of the rubber block crushing system of the waste truck tire casing crushing robot is characterized in that:

[0042] Step 1, the coarse crushing gear roller 16 includes a roller 1, a key strip 2, a cutter wheel set 3, a prestressed ring anchor cable 4, and the prestressed ring anchor cable 4 tightly binds four cutter heads 8 into one cutter wheel 5 , and then the cutter wheel 5 is inserted into the roller 1 to form the cutter wheel group 3 according to the order of high and low order. Mold precision casting, the material is preferably ZG270-500, annealed after casting, quenched and tempered after finishing, quenched and tempered hard...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com