Hydraulic damping supporting roller

A technology of hydraulic damping and supporting rollers, which is applied in the direction of rollers, earthwork drilling, underground transportation, etc. It can solve the problem of continuous sliding of the belt on the load, achieve smooth braking, avoid a large amount of accumulation, and use safe and reliable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

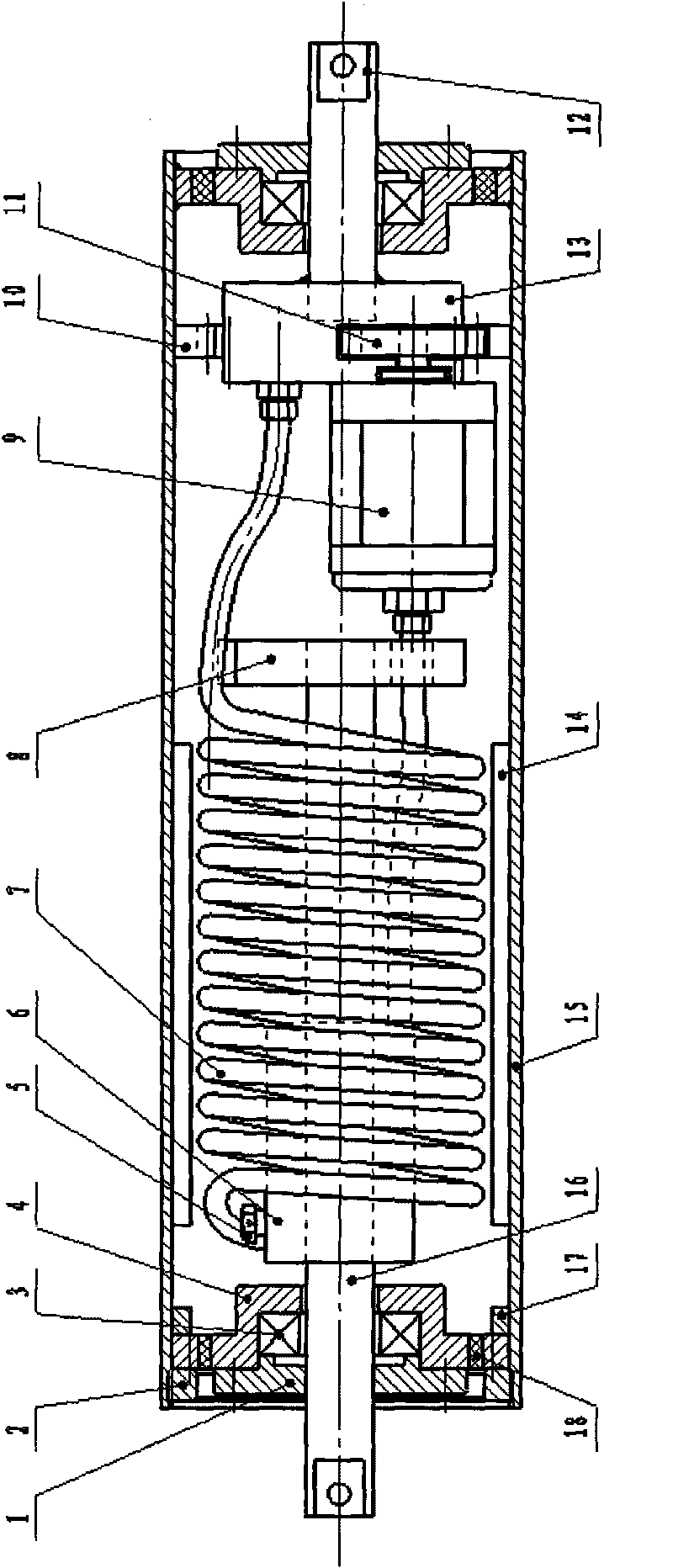

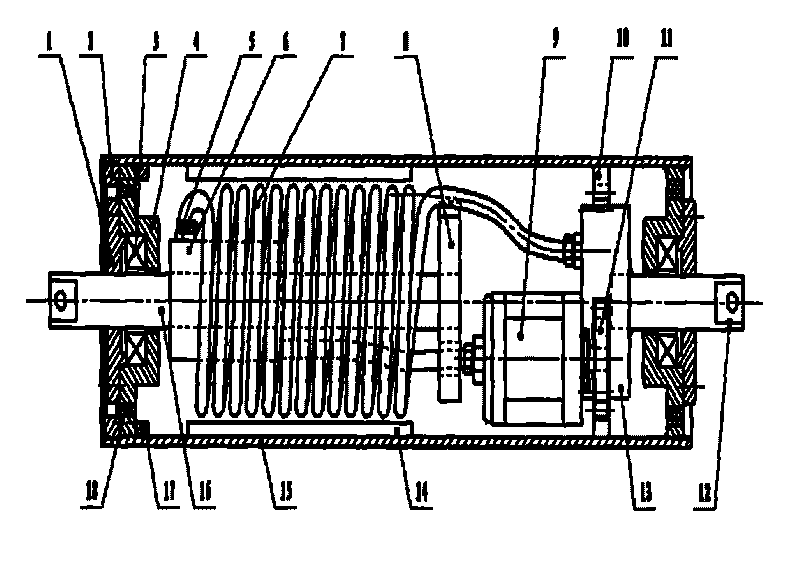

[0014] Such as figure 1 As mentioned above, the hydraulically adjustable damping roller of the present invention includes a mechanical device part and a hydraulic system part.

[0015] The mechanical device part includes bearing end cover 1, end face locking ring 2, snap ring 17, deep groove ball bearing with dust cover 3, bearing seat 4, idler tube body 15, internal meshing gear 10, external meshing gear 11, Ventilation dust filter 18, connecting fixed shaft I 12, fan blade 14, connecting fixed shaft II 16, pump fixing frame 13 and liquid pipe fixing frame 8.

[0016] The hydraulic system part includes oil tank, liquid pipe, positive displacement pump and air filter.

[0017] The composition wherein is that the bearing block 4 that cooperates with the connecting fixed shaft I 12 is welded together with the idler tube body 15, the pump fixing frame 13 is welded and fixed on the connecting fixed shaft I 12, and the liquid pipe fixing frame 8 is fixed on the connecting fixed sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com