Method for preparing octenylsuccinate potato starch ester

A technology of octenyl succinic acid and potato starch, applied in the field of preparation of octenyl succinate potato starch ester, can solve the problem of low overall benefit, weak construction of industrial technology support system, insufficient development of potato industry superiority and potential, etc. problem, to achieve the effect of overcoming the difficulty of emulsification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

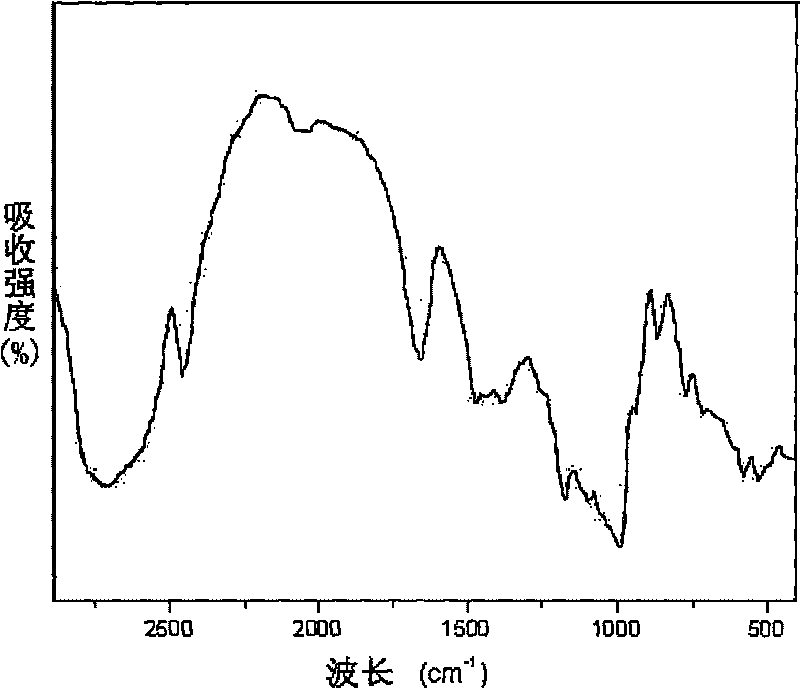

[0071] Embodiment 1 A kind of preparation method of octenyl potato starch succinate comprises the following steps:

[0072] (1) Mix 20kg of potato starch produced by Gansu Tengsheng Starch Co., Ltd. with 38kg of water, and stir at 30°C with a 100LBLD1.1-100 stainless steel steam heating constant temperature stirring reactor produced by Wuxi Dongguan Machinery Manufacturing Co., Ltd. A starch emulsion with a concentration of 35% is formed, and the pH value is adjusted to 7.5 with a sodium hydroxide solution having a mass concentration of 2%.

[0073] (2) Dilute 0.6 kg of octenyl succinic anhydride with 20 kg of Tween mixture to a solution with a concentration of 3%, wherein the Tween mixture refers to a mixture of 3 parts by mass of Tween and 95 parts by mass of water.

[0074] (3) Mix the starch emulsion with the diluted alkenyl succinic anhydride in the step (2), and put it into a 100LBLD1.1-100 type stainless steel steam heating constant temperature stirring reactor to react...

Embodiment 2

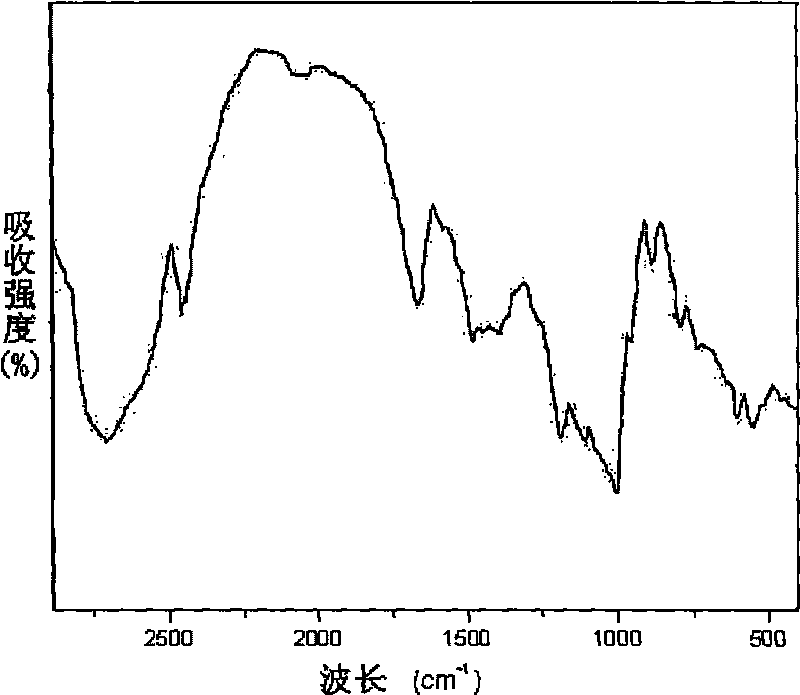

[0077] Embodiment 2 A kind of preparation method of octenyl potato starch succinate comprises the following steps:

[0078] (1) 20kg potato starch is mixed with 32.6kg water, and at 35 DEG C, it is stirred into a starch emulsion with a milk concentration of 38% with a stainless steel steam heating constant temperature stirring reactor, and the pH value is adjusted with a mass concentration of 2% sodium hydroxide solution to 7.7.

[0079] (2) Dilute 0.6 kg of octenyl succinic anhydride with 15 kg of Tween mixture to a 4% solution; wherein the Tween mixture refers to a mixture of 4 parts by mass of Tween and 96 parts by mass of water.

[0080](3) The starch emulsion is mixed with the alkenyl succinic anhydride diluted in the step (2), and put into a stainless steel steam heating constant temperature stirring reactor to react to form a reaction system, and then use a 2% NaOH solution with a mass concentration The pH value was kept at 7.7, and the reaction time was 3.5 hours unti...

Embodiment 3

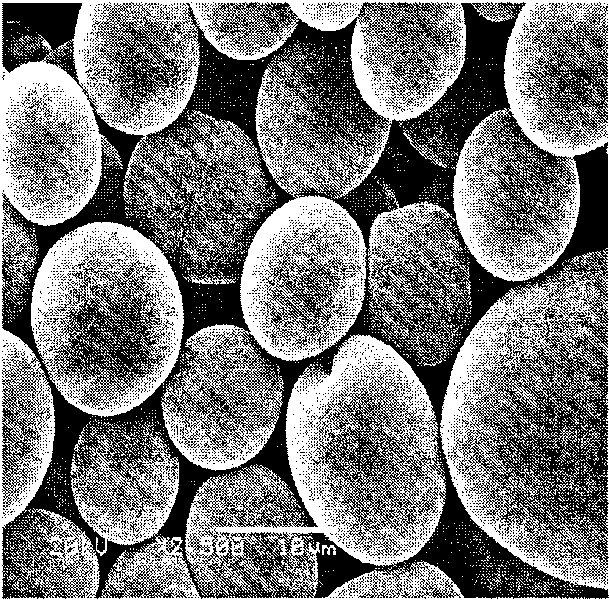

[0083] Embodiment 3 A kind of preparation method of octenyl potato starch succinate comprises the following steps:

[0084] (1) 20kg potato starch is mixed with 28kg water, and at 40 DEG C, it is a starch emulsion with a milk concentration of 42% to be stirred with a stainless steel steam heating constant temperature stirring reactor, and the sodium hydroxide solution with a mass concentration of 2% is used to adjust the pH value to 7.8.

[0085] (2) Dilute 0.6kg octenyl succinic anhydride with 12kg Tween mixed solution into a solution with a concentration of 5%; wherein the Tween mixed solution means that the solid-to-liquid ratio is 5 parts by mass of Tween and 97 parts by mass of water of the mixture.

[0086] (3) The starch emulsion is mixed with the alkenyl succinic anhydride diluted in the step (2), and put into a stainless steel steam heating constant temperature stirring reactor to react to form a reaction system, and then use a 2% NaOH solution with a mass concentrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com