Fatigue testing device for lateral dynamic bending of piston rod of vibration damper

A dynamic bending and fatigue test technology, applied in measuring devices, using repetitive force/pulse force to test the strength of materials, instruments, etc. Convenience and the effect of ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

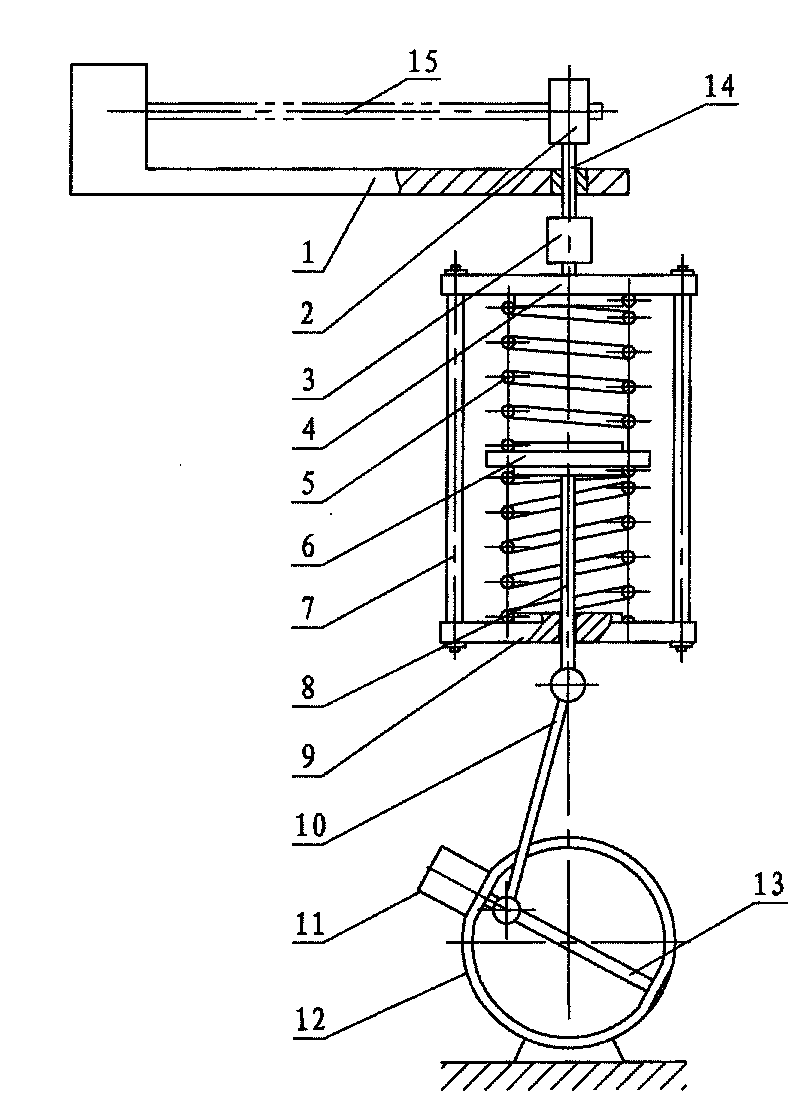

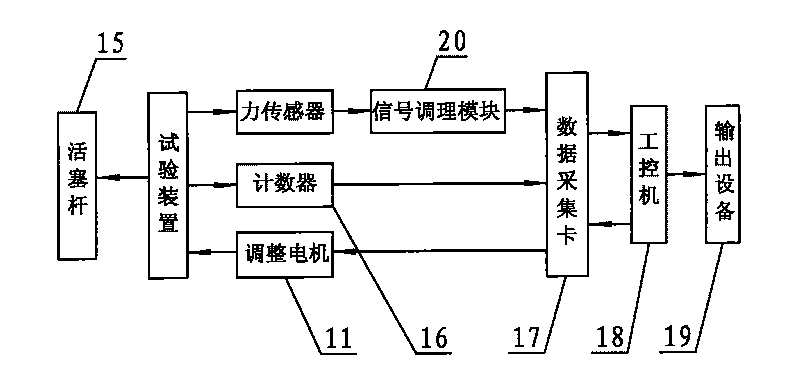

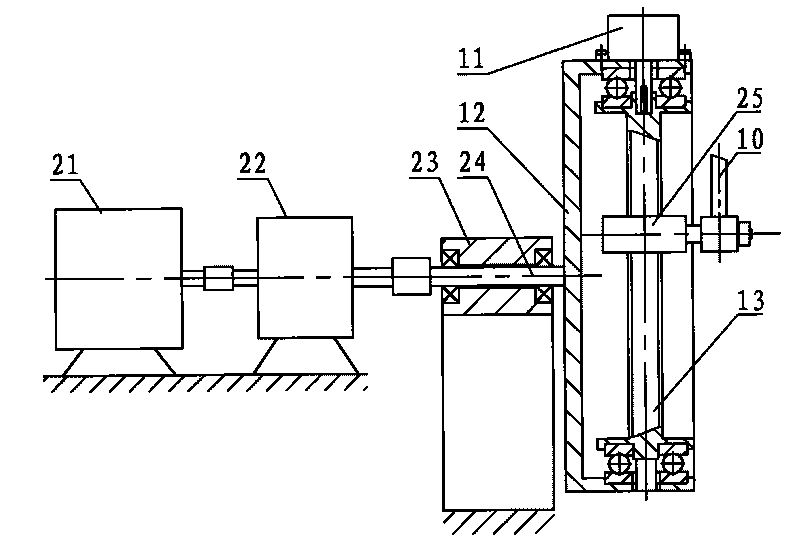

[0014] As shown in the figure, the shock absorber piston rod lateral dynamic bending fatigue test device has a simple harmonic motion mechanism driven by a driving device to provide simple harmonic excitation, and the driving device is composed of a driving motor 21 and a reducer 22 The simple harmonic motion mechanism is a crank-link slider mechanism, and a cam mechanism, a sheave mechanism or other mechanisms that can realize simple harmonic motion can also be used. This embodiment takes the crank-link slider mechanism as an example . The crank-link slider mechanism includes a shaft seat 23, on which a rotatable drive shaft 24 is installed, one end of the drive shaft 24 is connected with the speed reducer 22, and the other end is fixedly connected with the turntable 12, on the turntable 12 An adjusting screw 13 is installed on the radial direction through two sets of bearings. An adjusting motor 11 is fixed at one end of the adjusting screw 13 on the outer edge of the turnta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com