Liquid crystal mixture with low negative dielectric

A negative dielectric and mixture technology, applied in liquid crystal materials, chemical instruments and methods, etc., can solve the problems of good mutual solubility of liquid crystal and dyes, achieve uniform display effect, good absorbance and dichroic ratio, and improve display contrast. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

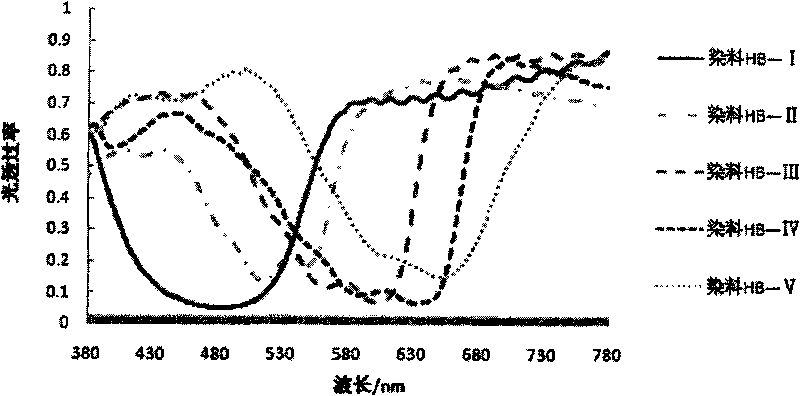

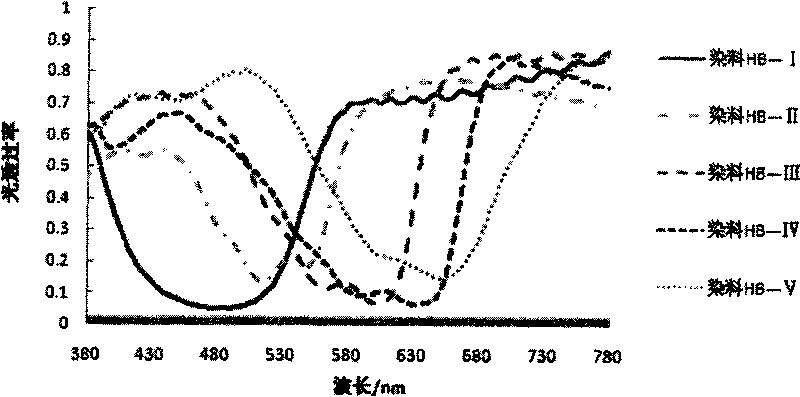

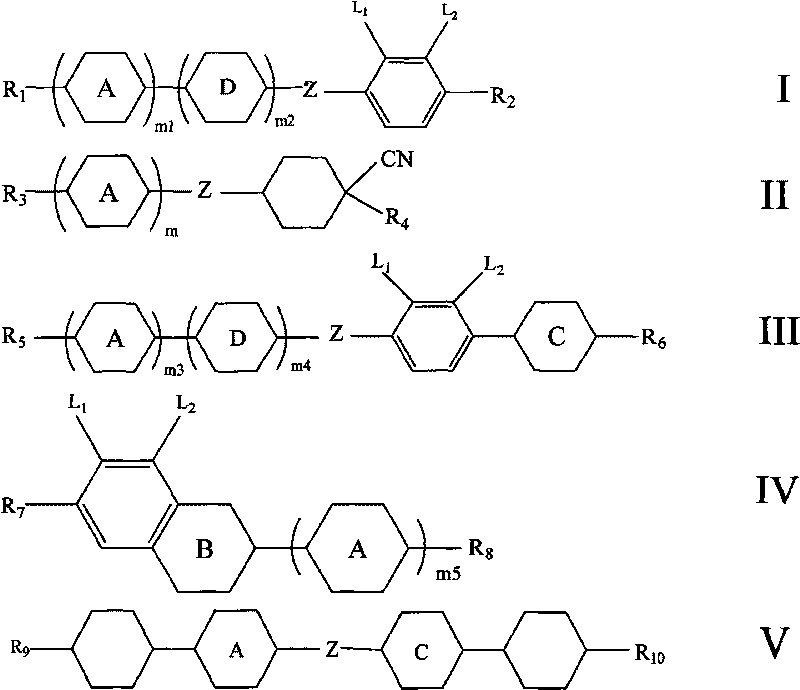

[0090] Add mixed violet dye-1 composed of dichroic dye monomers to 100 g of negative host liquid crystals of the present invention to form dye liquid crystals, and the composition ratio is shown in Table 2-1.

[0091] The composition of mixed purple dye-1 (1.6g) is:

[0092] Dichroic dye HB-I: 0.2000g

[0093] Dichroic dye HB-III: 0.8000g

[0094] Dichroic dye HB-IV: 0.6000g

[0095] Table 2-1 Main liquid crystal composition and proportion of Example 1

[0096] Liquid crystal compound (indicated by code)

parts by weight

3AAEMO2

6

3AEMO1

20

4AAEAA3

3

5AAEAA3

3

3AMO2

10

2AMPO2

8

3AMO4

9

5AMO4

9

[0097] Liquid crystal compound (indicated by code)

parts by weight

3AAMO2

7

5AAMO2

6

4AAMO2

7

3AAMO3

6

3AAM1

6

Mix Purple Dye - 1

1.6

[0098] The dye liquid crystal is poured b...

Embodiment 2

[0102] Add mixed blue dye-2 composed of dichroic dye monomers to 100 g of negative host liquid crystals of the present invention to form dye liquid crystals, and the composition ratio is shown in Table 3-1.

[0103] The composition of mixed blue dye-2 (1.9g) is:

[0104] Dichroic dye HB-I: 0.2000g

[0105] Dichroic dye HB-III: 0.2000g

[0106] Dichroic dye HB-IV: 1.5000g

[0107] Table 3-1 Main liquid crystal composition and proportion of Example 2

[0108] Liquid crystal compound (indicated by code)

[0109] The dye liquid crystal was poured between the two substrates of the liquid crystal display for performance testing, and the data are shown in Table 3-2.

[0110] Table 3-2 Performance test data of Example 2

[0111] Test items

[0112] Test items

Embodiment 3

[0114] Add mixed black dye-3 composed of dichroic dye monomers to 100 g of negative host liquid crystals of the present invention to form dye liquid crystals, and the composition ratio is shown in Table 4-1.

[0115] The composition of mixed black dye-3 (2.0g) is:

[0116] Dichroic dye HB-I: 0.4000g,

[0117] Dichroic dye HB-II: 0.7500g,

[0118] Dichroic dye HB-IV: 0.8500g;

[0119] Table 4-1 Main liquid crystal composition and proportion of Example 3

[0120] Liquid crystal compound (indicated by code)

parts by weight

3AAEMO2

8

3AEMO1

13

4AAEAA3

1

5PTM3

3

3AAEN1

5

3PPEN2

4

3AMO2

7

2APMO2

5

3AMPO2

5

[0121] Liquid crystal compound (indicated by code)

parts by weight

3AMO4

8

5AMO4

8

3AW(5)

8

5AAMO2

8

4AAMO2

8

3AAMO3

9

Mixed Black Dye - 3

2.0

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com