Spatial three-dimensional translational degree of freedom (DOF) combination drive flexible cable parallel mechanism

A hybrid drive, three-dimensional translation technology, applied in the direction of manipulators, manufacturing tools, etc., can solve the problems of driving parallel robots with flexible cables, etc., and achieve the effects of wide practicability, easy disassembly and assembly, and large working space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

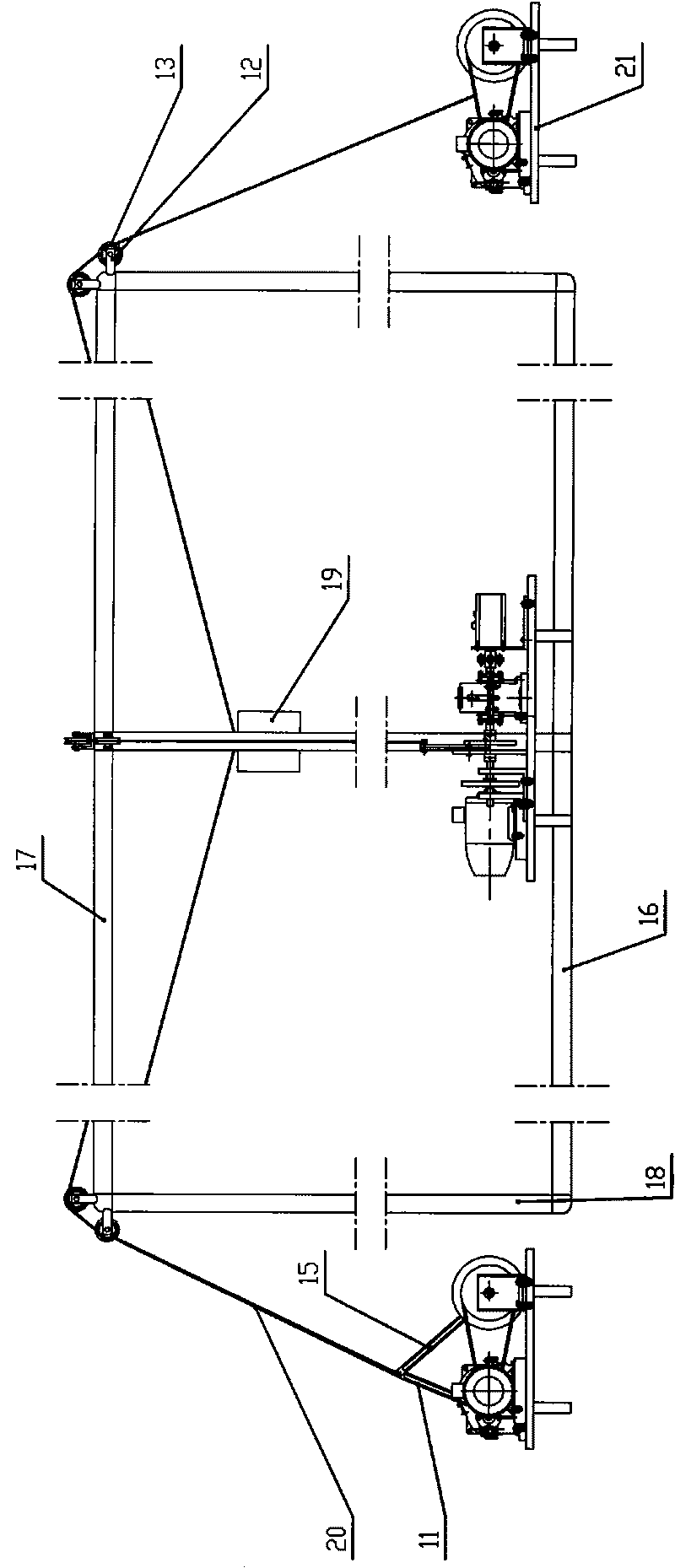

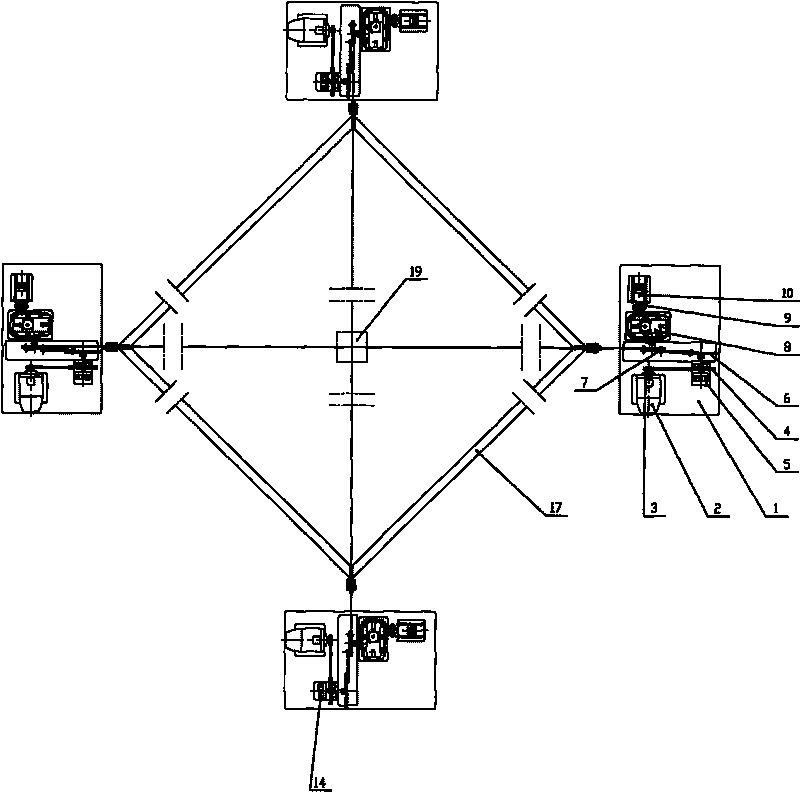

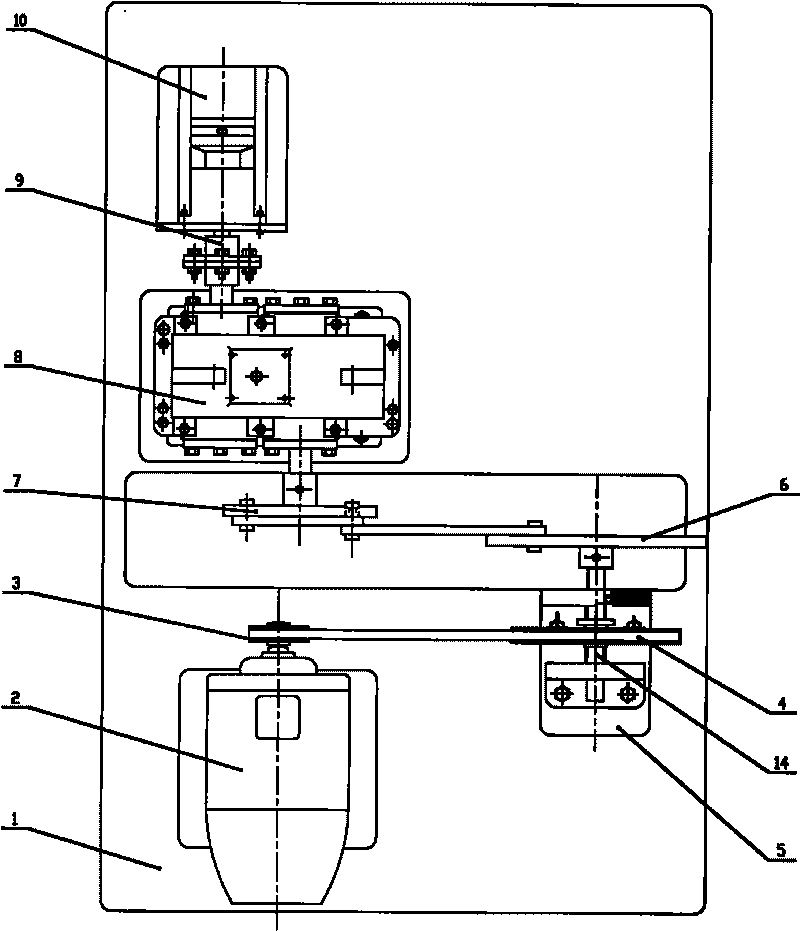

[0012] The present invention will be further described below in conjunction with the embodiment in the accompanying drawings:

[0013] The present invention realizes the space three-dimensional translation degree of freedom hybrid drive flexible cable parallel mechanism, which is composed of four sets of hybrid drive double crank five-link mechanism 1 with the same structure, a cable tower bracket 18 and four flexible cables 20 for pulling heavy objects 19 . Four sets of hybrid drive double crank five linkage mechanisms 1 are symmetrically arranged in a cross shape, and the cable tower bracket 18 is arranged on the inner side of four sets of hybrid drive double crank five linkage mechanisms. Crossbeam 16 under the tower and crossbeam 17 on pylon constitute, are parallelogram, all are provided with soft cable guide pulley 13 on every column, flexible cable guide pulley 13 is two, arranges at right angles, is fixed on column by pulley support 12. The hybrid drive double-crank f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com