Temperature-sensing discoloring cloth

A technology of temperature-sensitive discoloration and color paste, which is applied in the field of temperature-sensitive discoloration cloth, can solve the problems of three-layer structure manufacturing process difficulty, high cost, unfavorable promotion and application, etc., so as to improve living standards, wash fastness and discoloration The effect of vividness improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

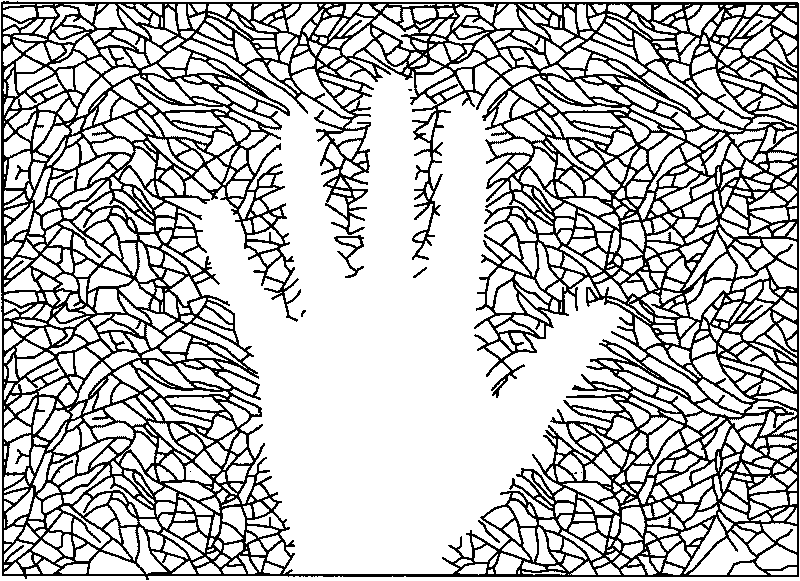

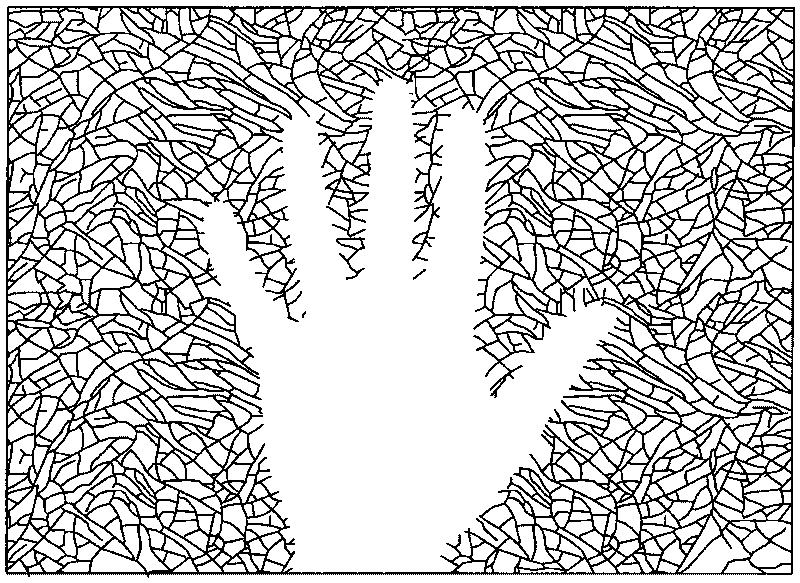

Image

Examples

Embodiment 1

[0044]Embodiment 1: a temperature-sensitive color-changing cloth, consisting of a base cloth and a printing coating or a full-board printing coating, the printing coating or the full-board printing coating is printed on the base cloth by a color paste through a printing process. On the surface, the formula of the color paste mainly contains the following ingredients:

[0045] (1) 45 parts by weight of carrier;

[0046] The carrier is a solvent-based polyurethane coating agent;

[0047] (2) Solvent

[0048] 6 parts by weight of dimethylformamide;

[0049] 15 parts by weight of butanone;

[0050] (3) 3 parts by weight of bridging agent;

[0051] Described bridging agent adopts polyisocyanate;

[0052] (4) 21 parts by weight of reversible thermochromic powder.

[0053] The reversible thermochromic powder is gray when developing, and becomes colorless at 30°C.

[0054] Solvent-based polyurethane coating agent, dimethylformamide, methyl ethyl ketone and reversible thermochro...

Embodiment 2

[0056] Embodiment 2. A temperature-sensitive color-changing cloth, consisting of a base cloth and a printing coating or a full-board printing coating, the printing coating or the full-board printing coating is printed on the base cloth by a color paste through a printing process. On the surface, the formula of the color paste mainly contains the following ingredients:

[0057] (1) 60 parts by weight of carrier;

[0058] The carrier is a solvent-based polyurethane coating agent;

[0059] (2) Solvent

[0060] 7 parts by weight of dimethylformamide;

[0061] 10 parts by weight of butanone;

[0062] 21 parts by weight of toluene;

[0063] (3) 5 parts by weight of bridging agent;

[0064] The bridging agent adopts blocked isocyanate;

[0065] (4) 23.5 parts by weight of reversible thermochromic powder;

[0066] (5) Accelerator 3 parts by weight.

[0067] The reversible thermochromic powder is colorless at 20°C and turns purple at 30°C.

[0068] The process of printing the ...

Embodiment 3

[0069] Embodiment 3. A temperature-sensitive color-changing cloth, which is composed of a base cloth and a printing coating or a full-board printing coating. The printing coating or the full-board printing coating is printed on the base cloth by a color paste through a printing process. On the surface, the formula of the color paste mainly contains the following ingredients:

[0070] (1) 50 parts by weight of carrier;

[0071] The carrier is a solvent-based polyurethane coating agent;

[0072] (2) Solvent

[0073] 5 parts by weight of dimethylformamide;

[0074] 25 parts by weight of toluene;

[0075] (3) 5 parts by weight of bridging agent;

[0076] The bridging agent adopts polyisocyanate, blocked isocyanate or trimethylolpropane;

[0077] (4) 18 parts by weight of reversible thermochromic powder.

[0078] (5) Accelerator 3 parts by weight.

[0079] The reversible thermochromic powder is red at 30°C, blue at 40°C, and purple at 70°C.

[0080] The process of printing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com