White corundum block waste heat utilization system

A white corundum and waste heat technology, applied in the field of white corundum block waste heat utilization system, can solve problems such as non-compliance and unfavorable health of staff

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

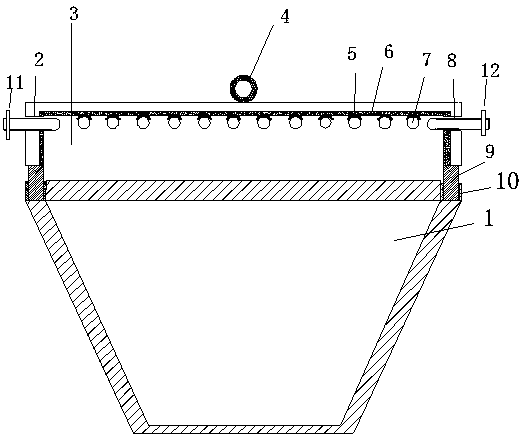

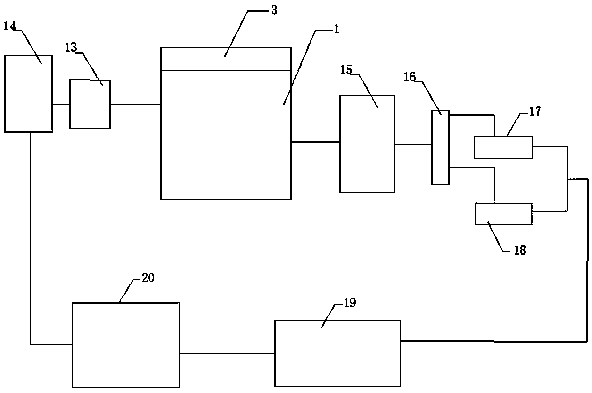

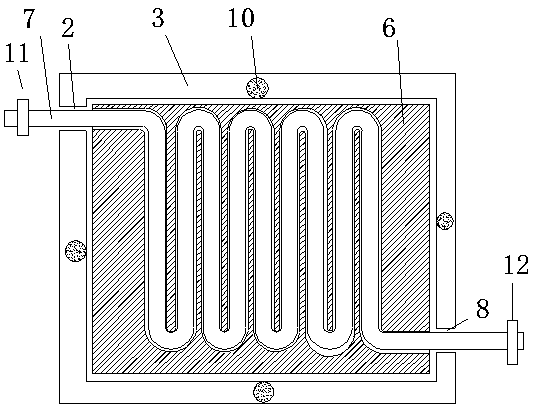

[0019] like figure 1 - Shown in 4: a white corundum block waste heat utilization system, including a cooling pool 1, the cooling pool 1 is a quadrangular pyramid structure with a large upper part and a smaller lower part, and a heat collecting cover is arranged above the cooling pool 1 3. The heat collecting cover 3 is a square frame structure, and the upper left side of the heat collecting cover 3 is provided with a pipe hole A2 for installing a quick heat pipe 7, and the fast heat water pipe 7 penetrates through the pipe hole A2 In the heat collecting cover 3, the part of the fast heat water pipe 7 placed in the heat collecting cover 3 is coiled on the upper wall of the heat collecting cover 3, and is led out through the pipe hole B8 provided under the right side of the heat collecting cover 3; The inner upper wall and the inner side wall o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com