Preparation method of wool self-cleaning fabrics

A self-cleaning and wool technology, applied in the field of wool self-cleaning fabric preparation, can solve problems such as hindering the practicality of wool fibers, difficult application of colloids, weak wettability of wool fibers, etc., achieving broad application prospects and development prospects, and low cost. , the preparation method is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

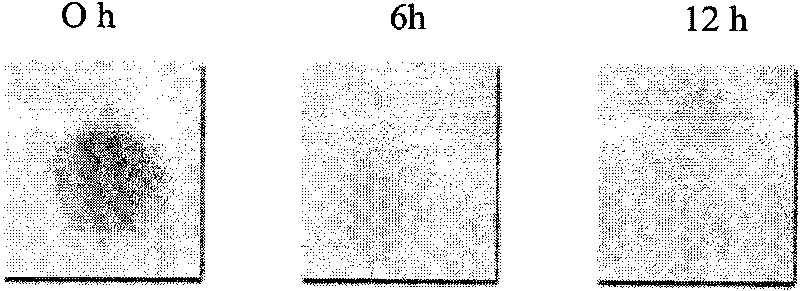

Image

Examples

Embodiment 1

[0032] (1) Preparation of anatase nano-titanium dioxide sol

[0033] Stir 4-isopropoxide titanium with a mass fraction of 97%, glacial acetic acid and 37% hydrochloric acid at 60°C for 12 hours to form a stable and transparent sol, then add wetting agent Tween 80, the molecular formula is as follows

[0034] Wherein the concentration ratio of titanium 4-isopropoxide, glacial acetic acid and hydrochloric acid is 1:1:0.28, and the wetting agent accounts for 0.1% of the mass of the sol;

[0035] (2) Surface self-cleaning finishing

[0036] The woolen fabric was pre-cleaned with Sandoclean PC non-ionic detergent, owf: 2%, at 40°C for 30 minutes to remove impurities before self-cleaning finishing, and the dried sample was soaked in titanium dioxide sol for 10 minutes, and washed at 1.75kg / cm 2 Roll the cloth on a padding car with a rotation speed of 7.5rpm, preheat the sample at 50°C for 2 minutes in the oven, and then bake the sample at 110°C for 2 minutes in the oven;

[0037...

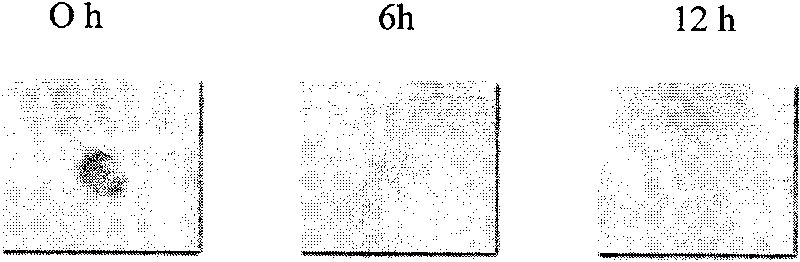

Embodiment 2

[0044] (1) Preparation of anatase nano-titanium dioxide sol

[0045] Stir 4-isopropoxide titanium, glacial acetic acid and 37% hydrochloric acid at 63°C for 14 hours with a mass fraction of 97% to form a stable and transparent sol, then add wetting agent Triton 100 Tween 80, its molecular formula is as follows :

[0046] Wherein the concentration ratio of titanium 4-isopropoxide, glacial acetic acid and hydrochloric acid is 1.2: 1.2: 0.35, and the wetting agent accounts for 0.3% of the mass of the sol;

[0047] (2) Surface self-cleaning finishing

[0048] The woolen fabric was pre-cleaned with Sandoclean PC nonionic detergent, owf: 3%, at 43°C for 37 minutes to remove impurities before self-cleaning finishing. Immerse the dried sample in titanium dioxide sol for 15 minutes, and 2 Roll the cloth on a paddle car with a rotation speed of 7.5rpm, preheat the sample at 60°C for 3 minutes in the oven, and then bake the sample at 115°C for 2.5 minutes in the oven.

[0049] (3) ...

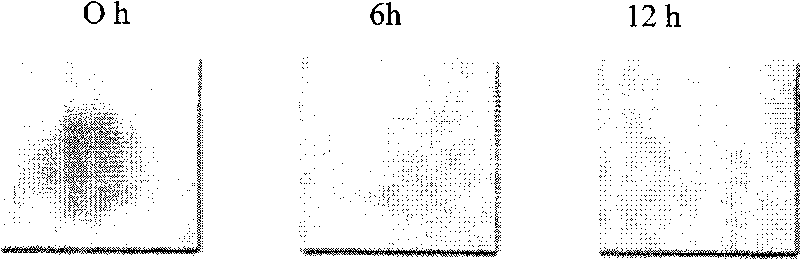

Embodiment 3

[0056] (1) Preparation of anatase nano-titanium dioxide sol

[0057] The mass fraction is 97% (titanium 4-isopropoxide, glacial acetic acid and 37% hydrochloric acid are stirred at 65 ℃ for 16 hours to form a stable and transparent sol, then add wetting agent Triton 100, its molecular formula is as follows :

[0058] Wherein the concentration ratio of titanium 4-isopropoxide, glacial acetic acid and hydrochloric acid is 1.5: 1.5: 0.45, and the wetting agent accounts for 0.5% of the mass of the sol;

[0059] (2) Surface self-cleaning finishing

[0060] The wool fabric was pre-cleaned with Kieralon OL non-ionic detergent, owf 4%, at 45°C for 45 minutes to remove impurities before self-cleaning finishing. The dried sample was immersed in titanium dioxide sol for 20 minutes, and the 2 Roll the cloth on a paddle car with a rotation speed of 7.5rpm, preheat the sample at 70°C for 5 minutes in the oven, and bake the sample at 120°C for 3 minutes in the oven.

[0061] (3) Silico...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com