Horizontal shaft magnetic suspension wind driven generator

A wind turbine and magnetic levitation technology, which is applied to wind turbines, wind turbine combinations, and wind turbines in the same direction as the wind, can solve the problem of affecting the starting wind speed and wind energy conversion efficiency of the wind turbine, and cannot greatly reduce the starting wind speed of the wind turbine. The rotor system is completely suspended and other problems, to achieve the effect of reducing the number of control systems, reducing the complexity of the system, and reducing the difficulty of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

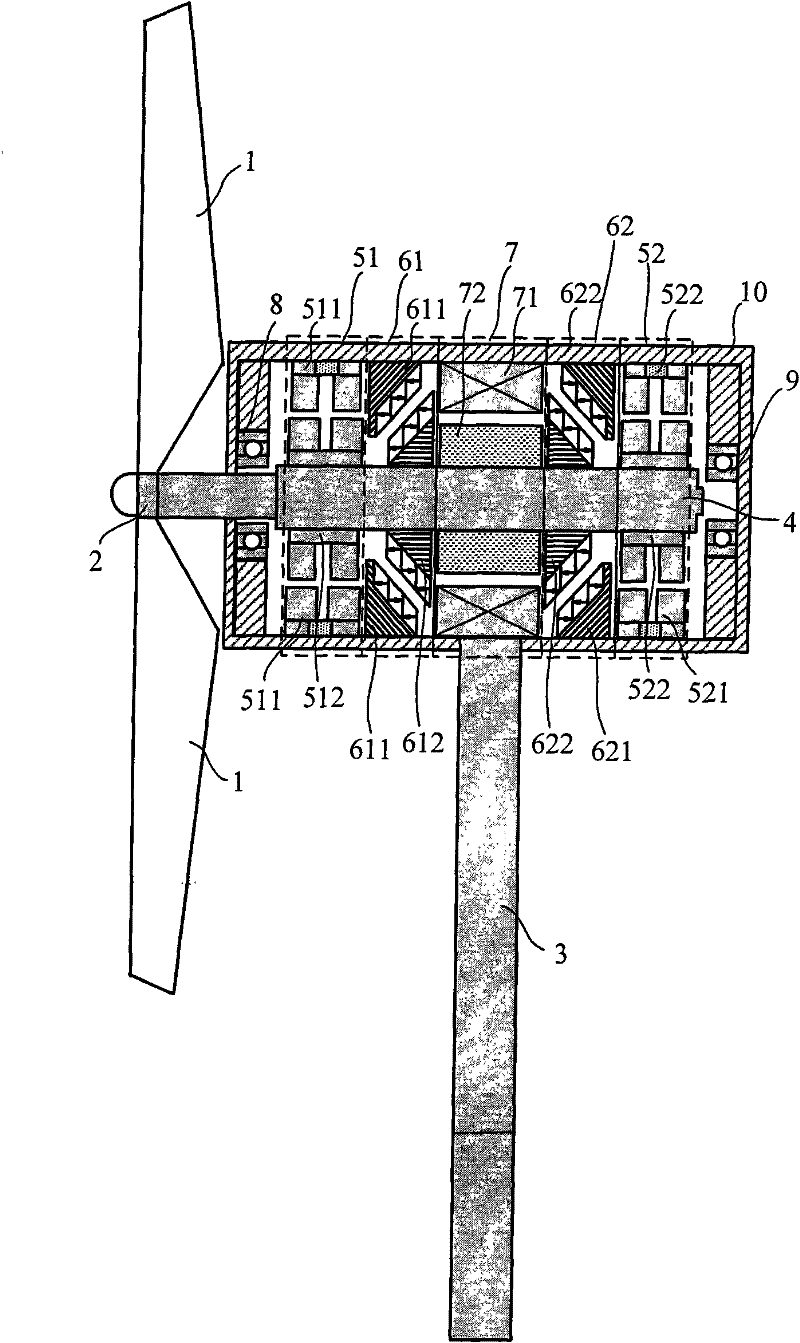

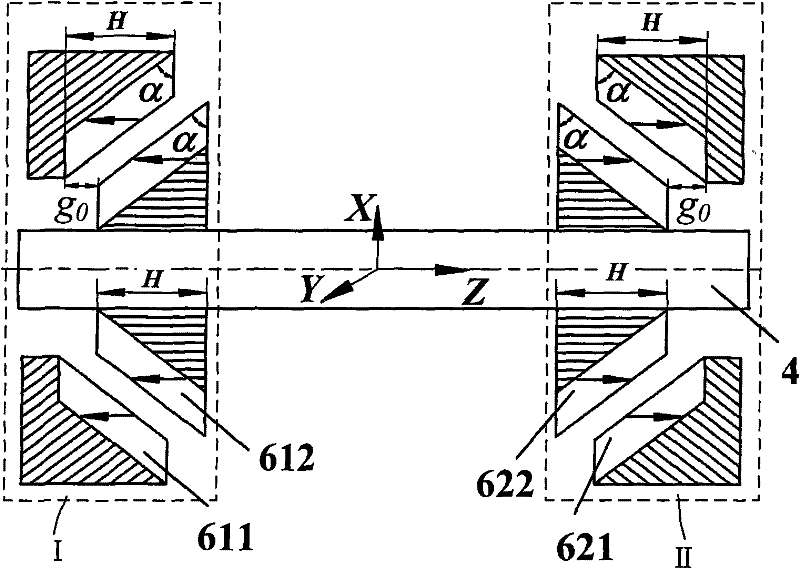

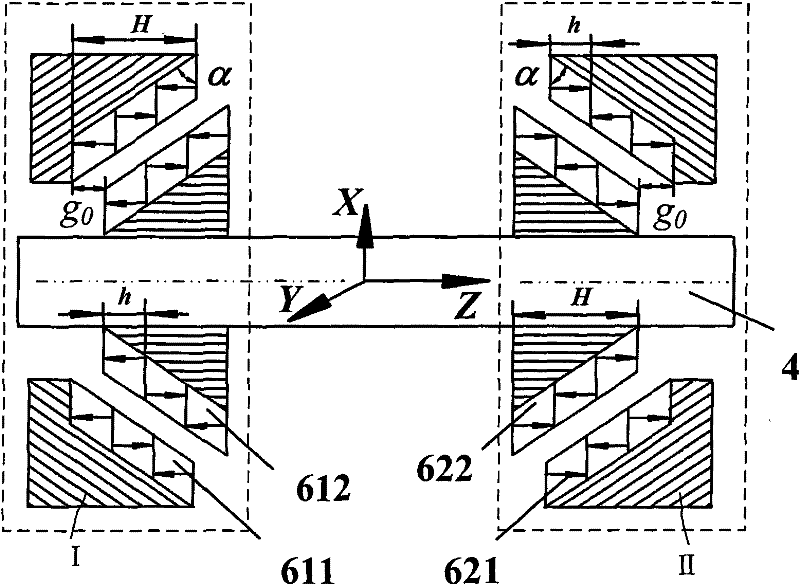

[0013] Such as figure 1 As shown, a horizontal-axis magnetic levitation wind power generator is composed of a stationary part and a rotating part. It is characterized in that the stationary part includes radial magnetic bearing stators 511 and 521, axial magnetic bearing stators 611 and 621, and front protective bearing 8 , Rear protective bearing 9, generator stator 71, stator housing 10 and wind turbine tower 3; the rotating parts include: blade 1, hub 2, radial magnetic bearing rotors 512 and 522, axial magnetic bearing rotors 612 and 622, power generation The rotor 72 and the rotating shaft 4; the fan blade 1, the front protective bearing 8, the front radial magnetic bearing 51, the front axial magnetic bearing 61, the generator 7, the rear axial magnetic bearing 62, the rear radial magnetic Bearing 52, rear protective bearing 9; where the fan blade 1 is installed on the hub 2, and the hub 2 is fixedly connected to the rotating shaft 4; the front protective bearing 8 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com