Device and method for testing absorbance by electric quantity method

A technology of testing devices and testing methods, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problem that it is difficult to accurately measure changes in the quality of adsorbents, it is impossible to simulate changes in the adsorption capacity of adsorbents, and it is impossible to accurately measure the temperature of adsorbents, etc. problem, to achieve the effect of cheap measuring equipment, wide range of test conditions and low test cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

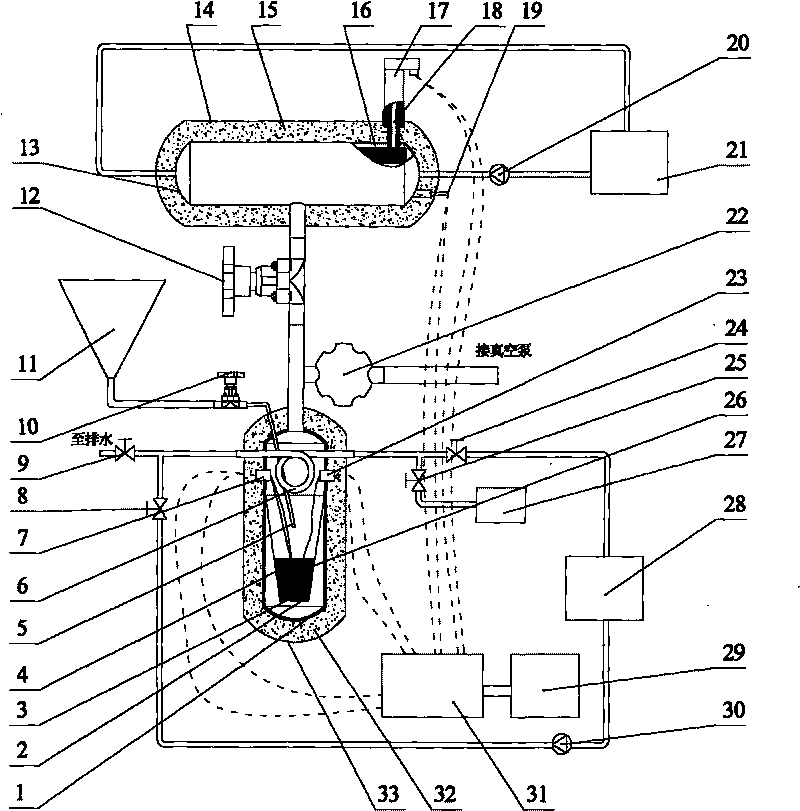

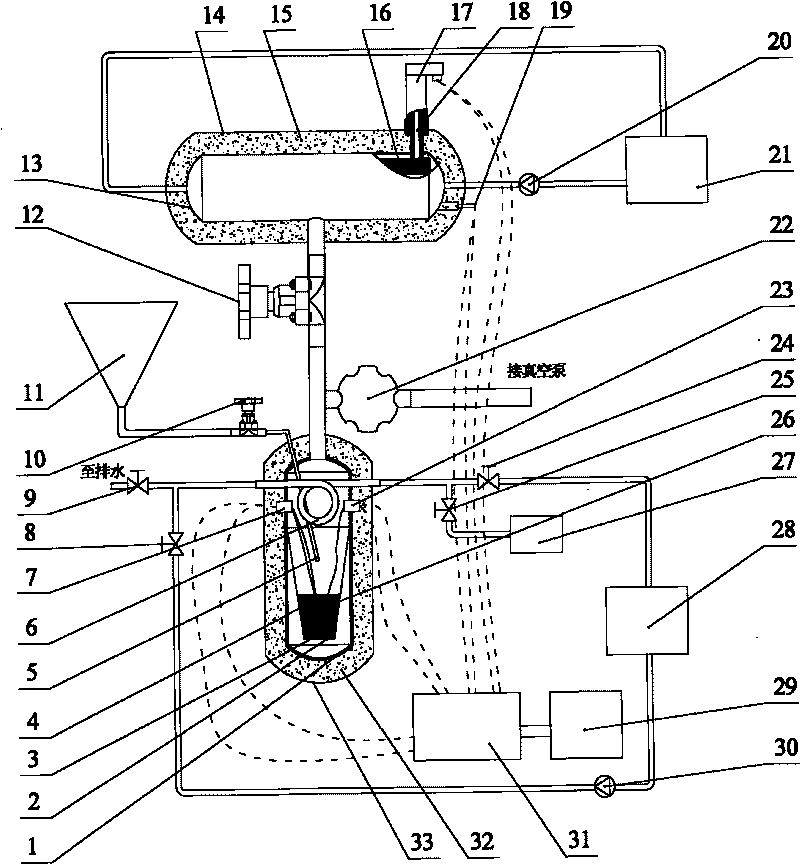

[0036] see figure 1, an electric quantity method adsorption capacity test device, including adsorber 14, evaporation / condenser 33, adsorber heating / cooling circuit composed of water pump 20 and constant temperature hot / cold water bath 21 and corresponding pipes, water pump 30 and constant temperature water bath 28 Evaporator / condenser cooling water circuit, compressed air purging system, data acquisition and heater control system composed of corresponding pipelines, and also includes the evacuation vacuum valve 22 and the switching vacuum valve 12 between the adsorber and the evaporator / condenser . The adsorber 14 and the evaporator / condenser 33 are connected by piping.

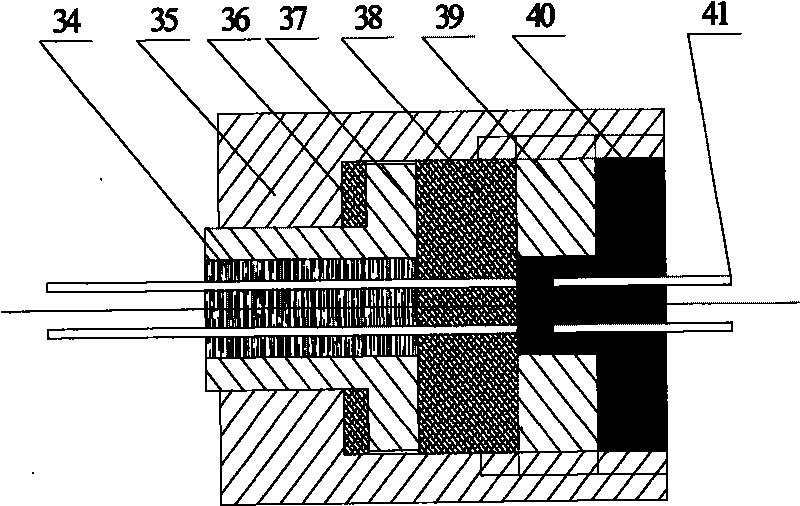

[0037] The above-mentioned adsorber 14 is formed by sealing the adsorber core group 16 with the adsorber shell 13, and is provided with a temperature sensor 19 for measuring the temperature of the adsorbent and a pressure sensor 17 for measuring the pressure in the adsorber. The pressure sensor 17 and the ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com