Tunnel boring machine two-dimensional loading analog test device

A technology for a tunnel boring machine and a simulation test is applied in the field of an experimental device for simulating a two-dimensional rock-breaking process of a tunnel boring machine, so as to achieve the effects of more test data, optimization of equipment parameters and construction parameters, and improvement of construction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The present invention will be described in further detail below according to accompanying drawing:

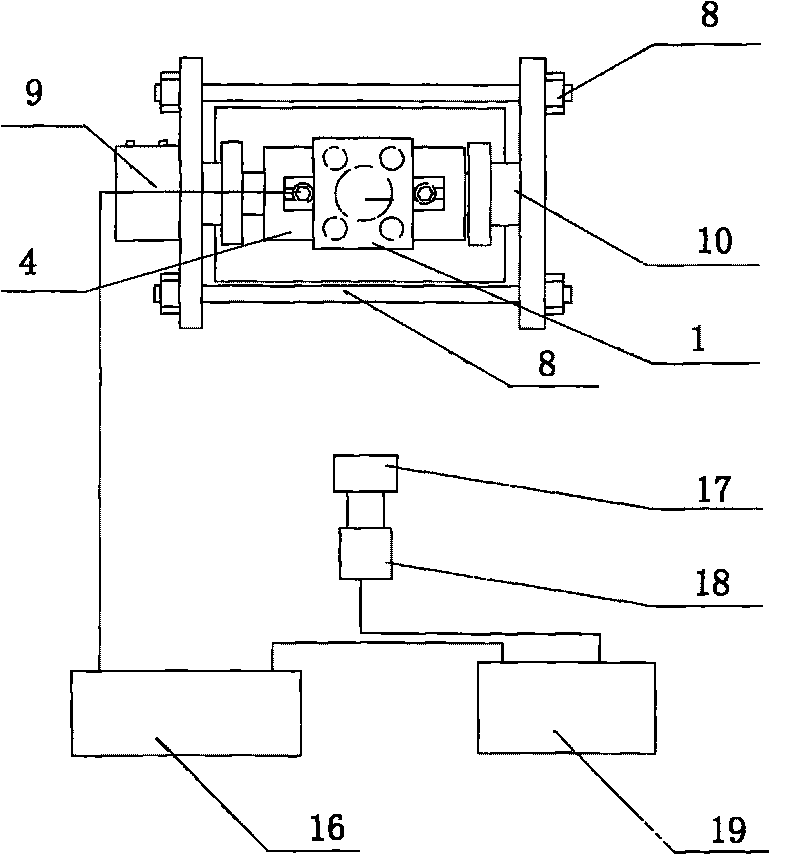

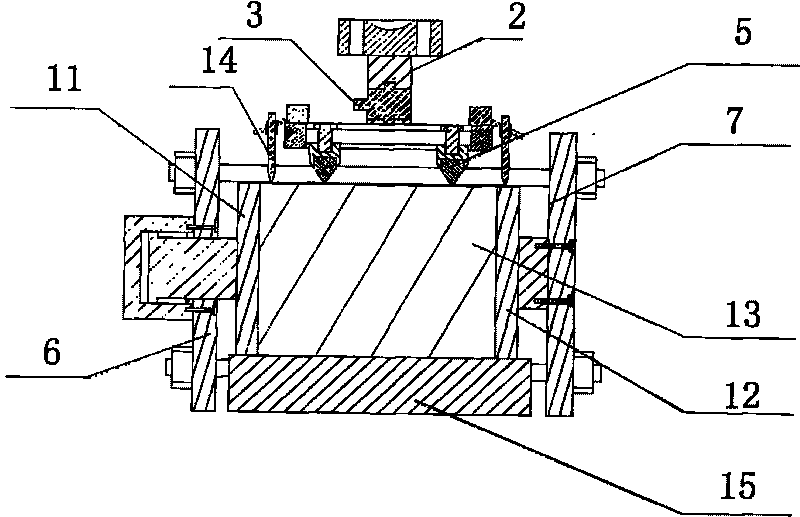

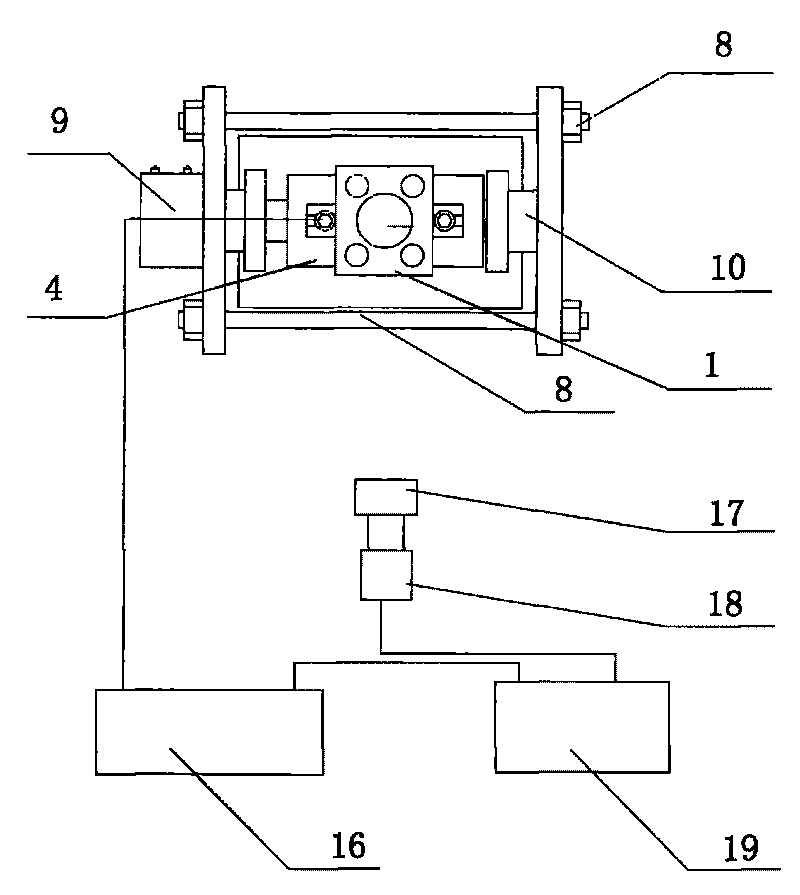

[0022] A two-dimensional loading simulation test device for a tunnel boring machine, which consists of a connection tester spherical pad 1, a vertical load transmission column 2, an axial load sensor (model: Interface WMC) 3, a tool holder 4, a tool 5, and a left side plate 6. Right side plate 7, tie rod 8, horizontal jack (model: YD-450) 9, horizontal load transmission column 10, left pressure plate 11 of test piece, right pressure plate 12 of test piece, test piece 13, Displacement sensor (model: WDB) 14, lower pressure plate of specimen 15, data sampler (model: CDSP) 16, zoom lens (model: Nikon AF-S DX) 17, high-speed CCD camera (model: BASLER A6411) 18 , computer 19, can be divided into 5 subsystems:

[0023]Vertical loading system: including spherical pad 1 connected to the testing machine, vertical load transmission column 2, axial load sensor 3, tool holder 4, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com