Tea microwave and ultrasonic wave combined dynamic countercurrent extraction method and equipment

A technology of dynamic countercurrent and extraction equipment, applied in the direction of tea extraction, etc., can solve the problems of easy chemical changes of active ingredients in tea, weak fragrance, high cost, etc., achieve automatic adjustment and online control, reduce the loss of active ingredients, and improve production yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

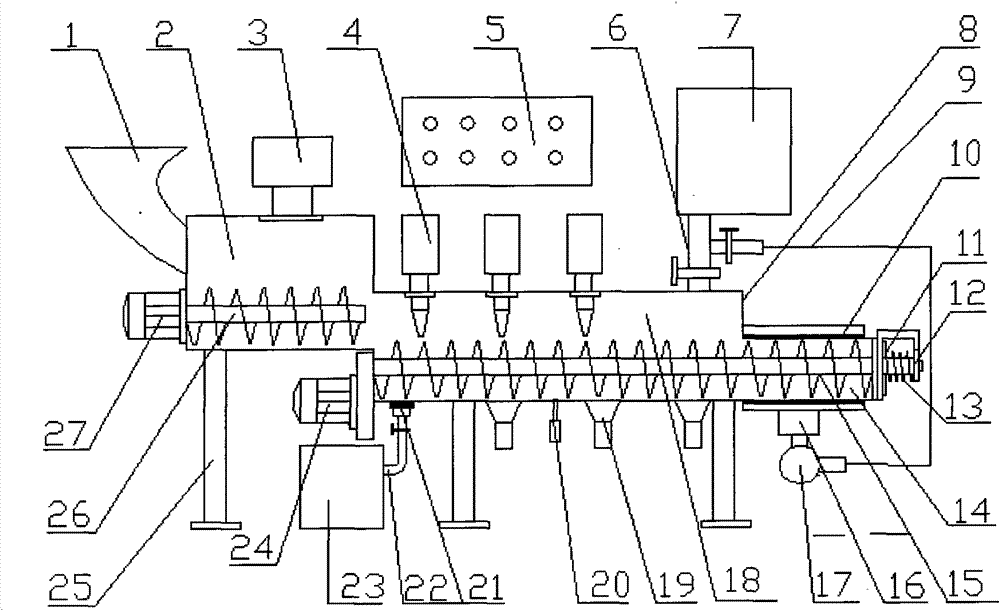

[0029] see figure 1 A tea microwave and ultrasonic combined dynamic countercurrent extraction equipment includes a frame 25 on which a housing 8 is fixed, and the housing 8 includes a microwave extraction chamber 2, an ultrasonic extraction chamber 18 and a solid-liquid separation chamber 14. It is in the shape of steps that decrease step by step. The side wall of the microwave extraction chamber 2 is provided with a feed inlet, connected to the hopper 1, and a rotating shaft is arranged in the microwave extraction chamber 2, and the first auger 26 is set on the rotating shaft. The microwave extraction chamber 2 is provided with a microwave generator 3 facing the first auger 26; a rotating shaft is also provided in the ultrasonic extraction chamber 2, and the rotating shaft passes through the ultrasonic extraction chamber 2 and the solid-liquid separation chamber 14 and extends out of the solid-liquid separation chamber 14 Outside, the end of the rotating shaft is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com