Automobile glass steel plastic instrument platform and manufacturing technology thereof

A manufacturing process, fiberglass technology, applied in the direction of instrument panels, glass/slag layered products, decorative arts, etc., can solve the problems that the general appearance cannot meet the decoration of luxury passenger cars, and the cost of luxury passenger car instrument panels is expensive, so as to achieve luxurious surface, The effect of low cost and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

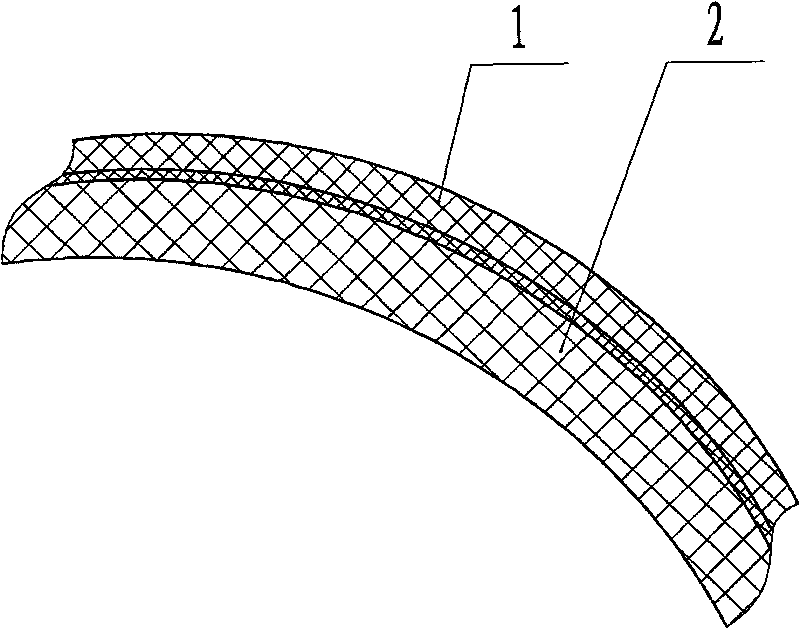

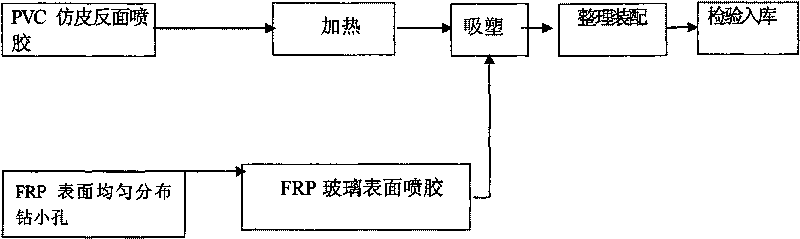

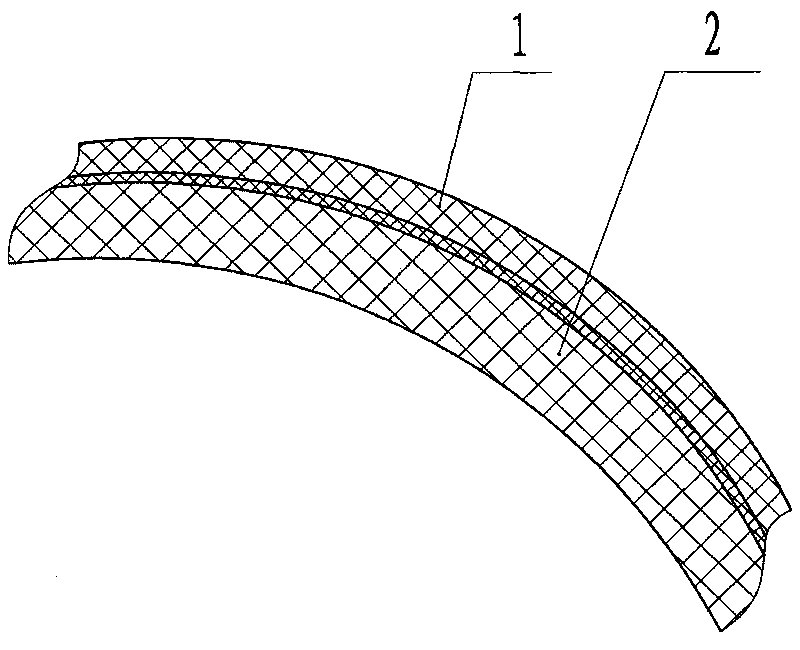

[0041] Such as figure 1 As shown, the body of the automobile instrument panel of the present invention is composed of a glass fiber reinforced plastic inner layer 2 and a PVC imitation leather surface layer 1 arranged on the surface of the glass fiber reinforced plastic inner layer 2 . Such as figure 2 As shown, during production, on the blister mold of the automobile dashboard, the processed FRP parts sprayed with polyurethane glue and the PVC imitation leather that has been heated and sprayed with polyurethane glue are absorbed, bonded and cured. Its specific manufacturing process steps are as follows:

[0042] 1. Processing of the inner layer of FRP

[0043] (1) Waxing and polishing the mold of the FRP instrument panel;

[0044] (2) Evenly paint the surface of the instrument panel mold with the adjusted unsaturated polyester resin;

[0045] (3) Lay a layer of glass fiber chopped strand mat on the first layer of the mold surface, and brush the adjusted unsaturated polye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com