Ozone generating tube

A technology of ozone generating tube and inner bile tube, applied in ozone preparation and other directions, can solve problems such as no airflow distribution, and achieve the effects of improving discharge uniformity, high generation concentration, and high ozone generation amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

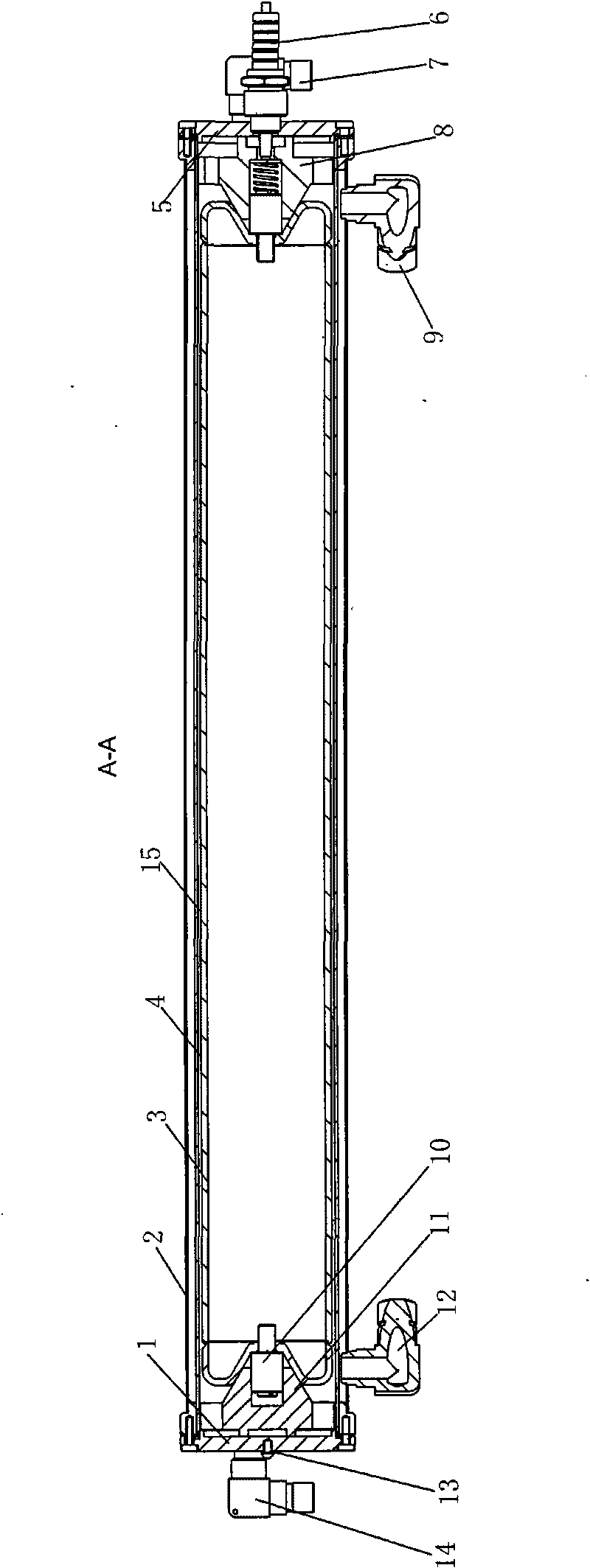

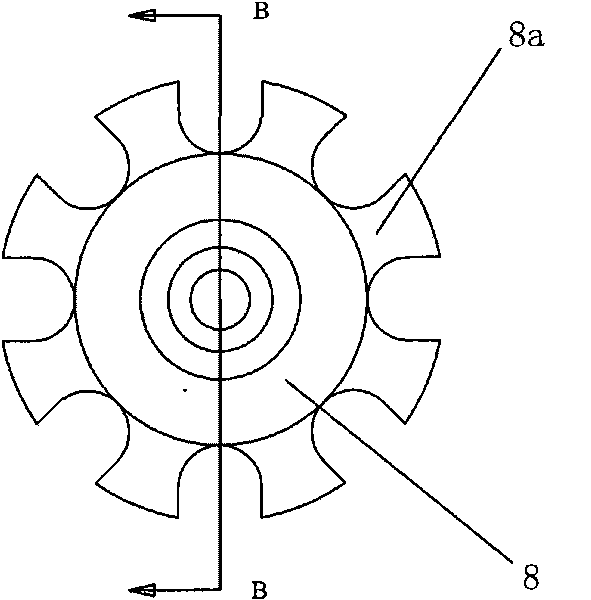

[0018] refer to Figure 1-6 , an ozone generating tube, comprising an inner spacer cover 2 and an inner bile duct 3 coaxially sleeved, the inner bile duct 3 is arranged in a hollow inner spacer 2, the inner spacer 2 and the inner bile duct 3 The air gap 15 for forming corona is formed between them, the dielectric insulating layer 4 is attached to the outer surface of the inner bile duct 3, and the front and rear cover joints 5, 1 are arranged at the two ends of the inner layer spacer sleeve 2, and the inner layer The two ends of the outer wall of the spacer 2 are respectively provided with cooling water inlet and outlet 12,9, and the front and rear cover joints 5,1 are respectively provided with inlet and outlet 7,14, and the air inlet 7 and the outlet The air ports 14 are all connected to the air gap 15, the back cover joint 1 is connected to the ground terminal 13, and the front cover joint 5 is connected to the high voltage input terminal 6; the inner electrode of the high ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com