Sand-dust blowing environment test device

An environmental test device, sand and dust technology, applied in measurement devices, aerodynamic tests, vehicle tests, etc., can solve the problems of increasing the frequency of runner reduction, reducing work reliability, increasing energy consumption, and improving dehumidification efficiency. And the effect of dehumidification reliability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. Here, it should be stated that the embodiments described in this specification and the structures drawn in the accompanying drawings are only preferred embodiments of the present invention, and are not limited thereto. Therefore, those skilled in the art should understand that various changes can be made to the following embodiments.

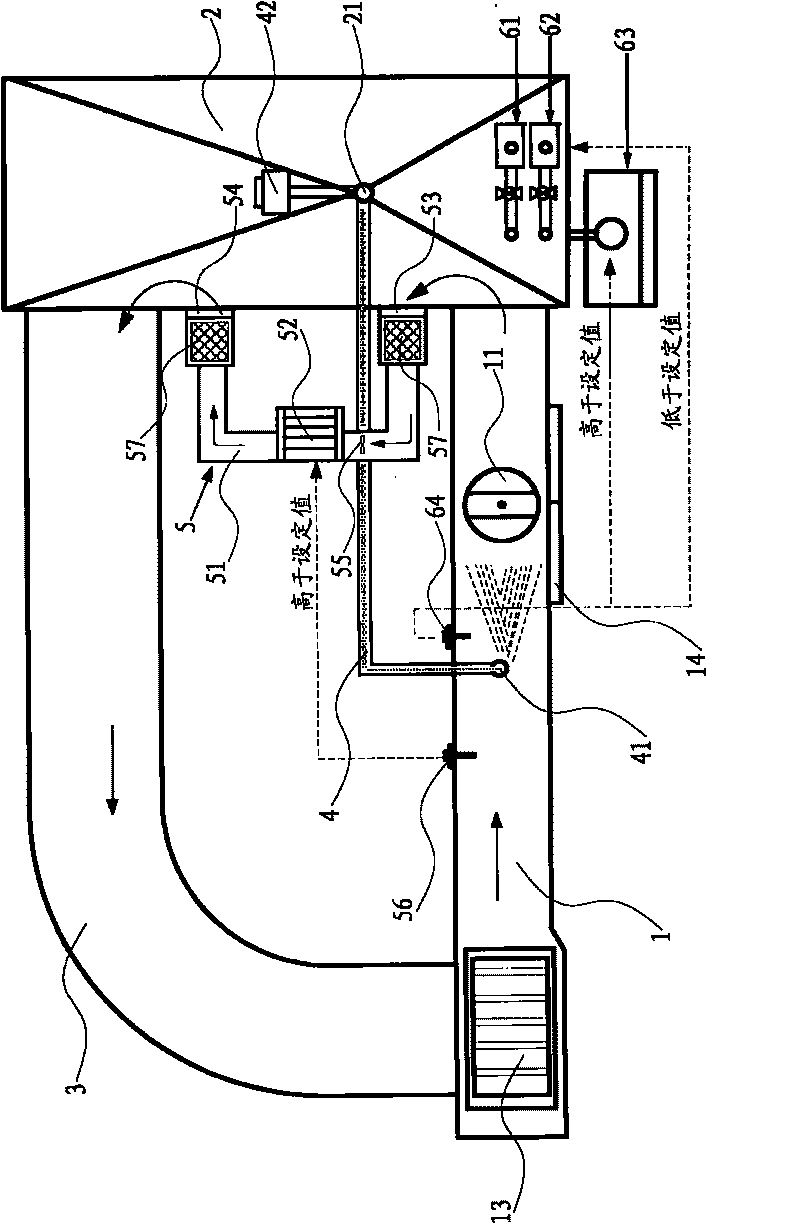

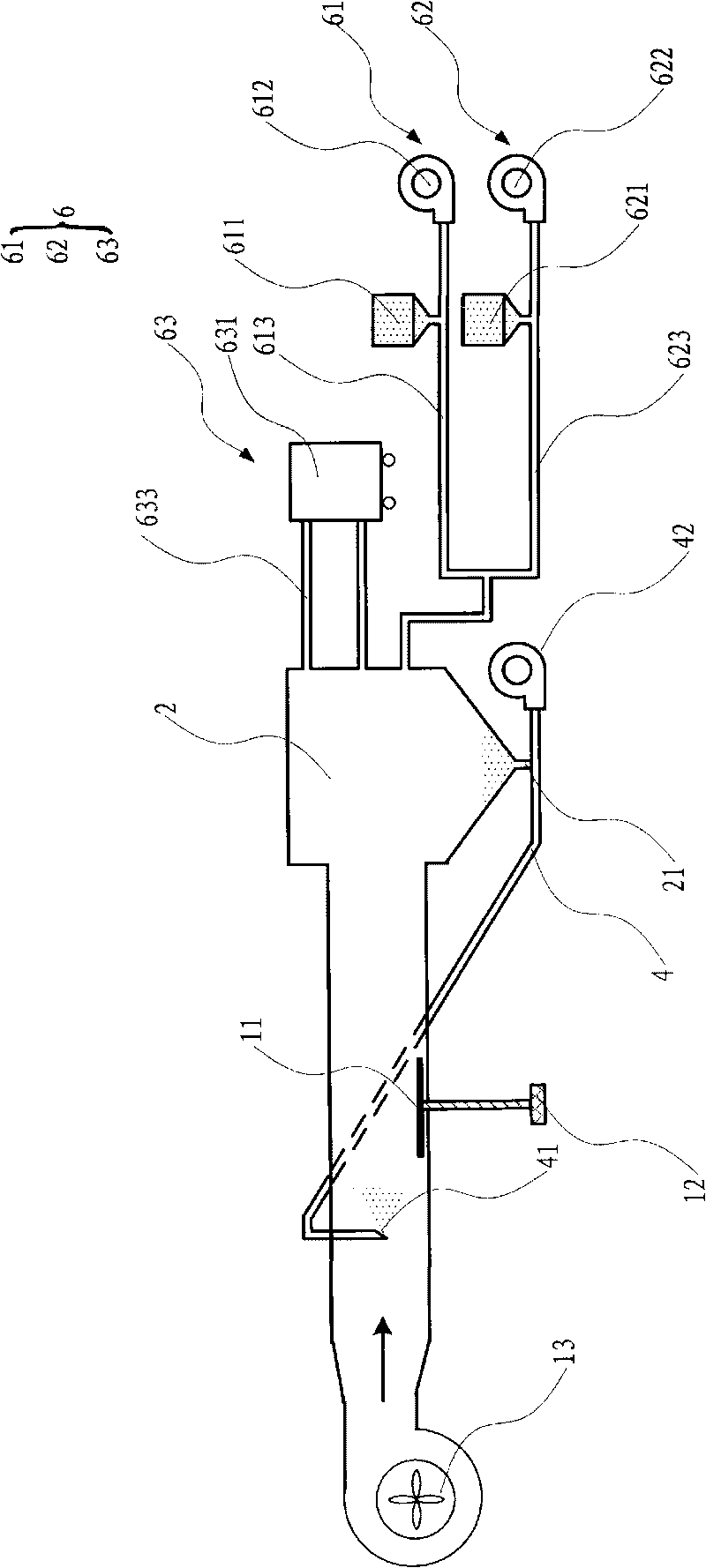

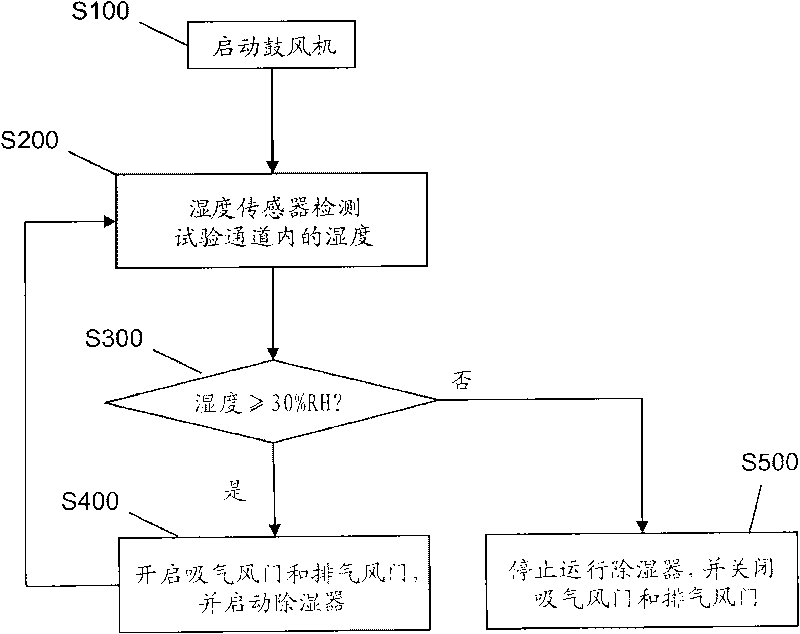

[0031] figure 1 It is a schematic plan view of the sand blowing dust blowing environmental test device of the present invention. Such as figure 1 As shown, the environmental test device for sand blowing and dust blowing of the present invention includes: a test channel 1 , a sand and dust separation device 2 , a return air channel 3 , a return pipe 4 and a dehumidification device 5 . Among them, the test passage 1, the sand and dust separation device 2 and the return air passage 3 are in closed-loop commun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com