Method for preparing wide wave reflective film by using polymer stabilized cholesteric phase liquid crystal material

A cholesteric liquid crystal and polymer technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of complex equipment, difficult process control, sensitivity to ultraviolet radiation intensity, etc., and achieve the effect of wide material sources and simple material system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

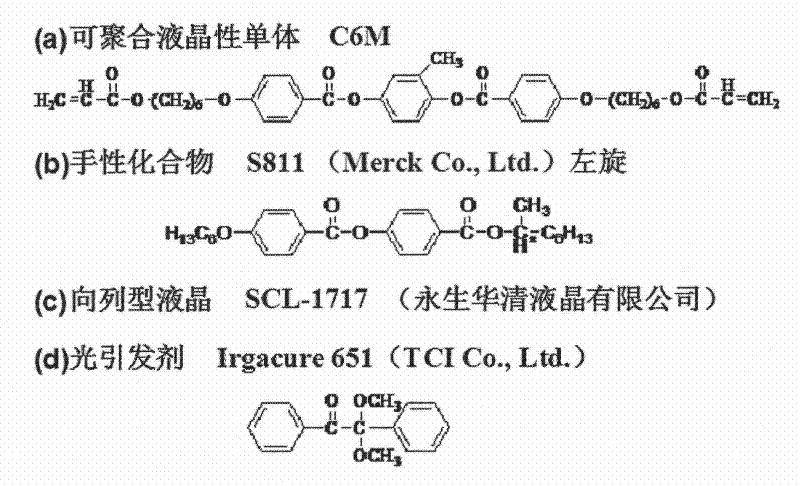

[0027]Mix C6M / SCL-1717 / S811=35.0% / 47.5% / 17.5% by mass ratio, then add photoinitiator and mix homogeneously (photoinitiator accounts for 0.5% of C6M gross weight) in the system, make mixed The ligand system is used as "mixture 1"; then C6M / SCL-1717 / S811=5.0% / 80.0% / 15.0% is mixed evenly according to the mass ratio, and then the photoinitiator is added to the system and mixed evenly (the photoinitiator accounts for the total amount of C6M 0.5% by weight), and a compounded system was prepared as "sample 2". The structural formulas or trade names of the materials used above are as follows: figure 1 shown.

[0028] The above-mentioned "mixture 1" was injected into a liquid crystal cell which had been planarly oriented in advance, and the thickness of the liquid crystal cell was 25.0 μm. Afterwards, heat-preserve the perfused liquid crystal cells at 343.2K for 15 minutes, so that the perfused compound system forms a stable planar texture, and irradiate the liquid crystal cells afte...

Embodiment 2

[0031] Mix C6M / SCL-1717 / S811=35.0% / 55.0% / 10.0% by mass ratio, then add photoinitiator and mix homogeneously (photoinitiator accounts for 0.5% of C6M gross weight) in the system, make mixed The ligand system is used as "mixture 2"; then C6M / SCL-1717 / S811=5.0% / 87.6% / 7.4% is mixed evenly by mass ratio, then photoinitiator is added to the system and mixed evenly (photoinitiator accounts for the total amount of C6M 0.5% by weight), and a compounded system was prepared as "Sample 5". The structural formulas or trade names of the materials used above are as follows: figure 1 shown. The pure polymer network of "Mixture 2" prepared according to the method of Example 1 is referred to as "Sample 4".

[0032] Inject the above "sample 5" into "sample 4", and irradiate with ultraviolet light again to cause polymerization and crosslinking between the molecules of photopolymerizable monomers, and record the diffusion process of "sample 5" in "sample 4" , at this point we call it "Sample 6"...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com