Muscle contracture prevention device for long-term bedridden patient

A patient and airbag technology, which is applied in the direction of hospital beds, medical science, hospital equipment, etc., can solve the problems of inconvenient disassembly, inability to care for the neck, and poor effect of preventing muscle contracture, so as to avoid muscle contracture, good effect of preventing muscle contracture, and avoid Effects of pressure ulcers and muscle contractures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

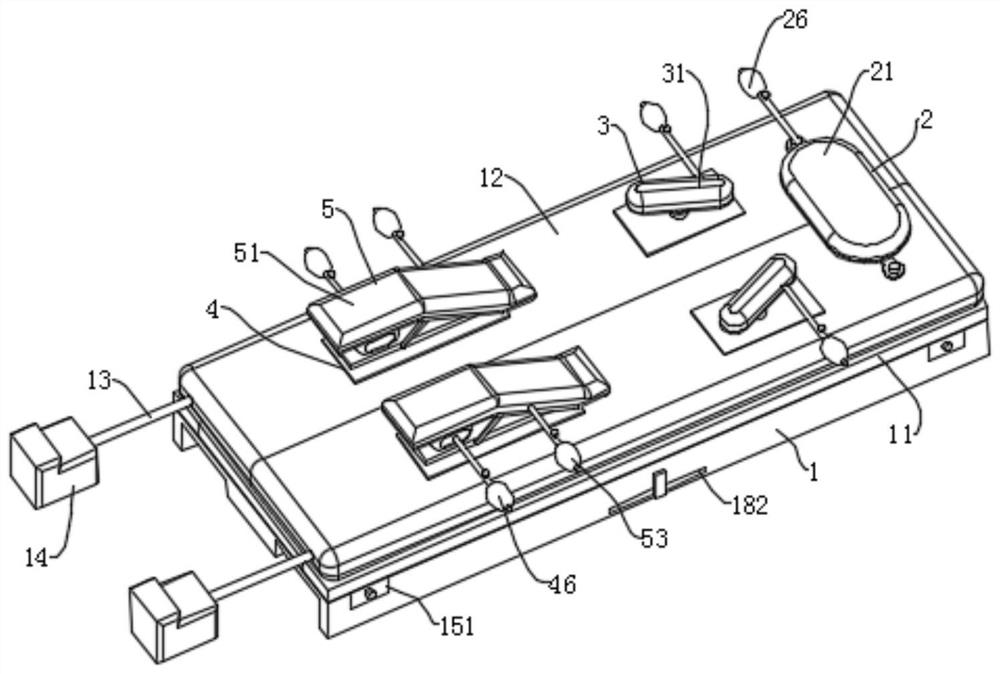

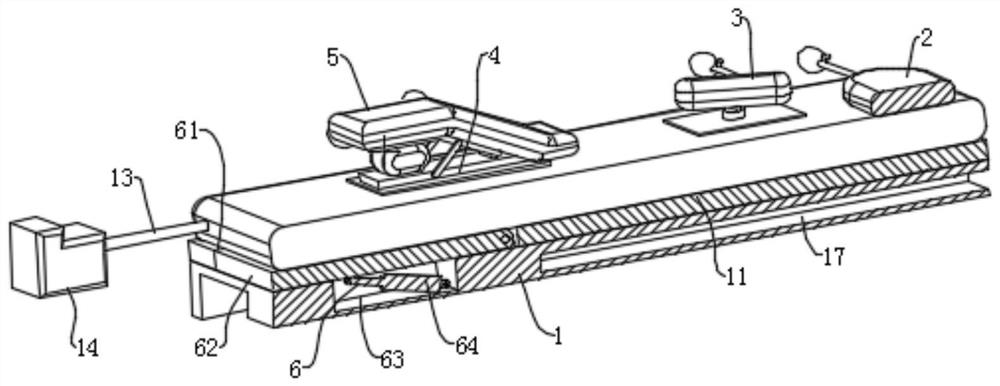

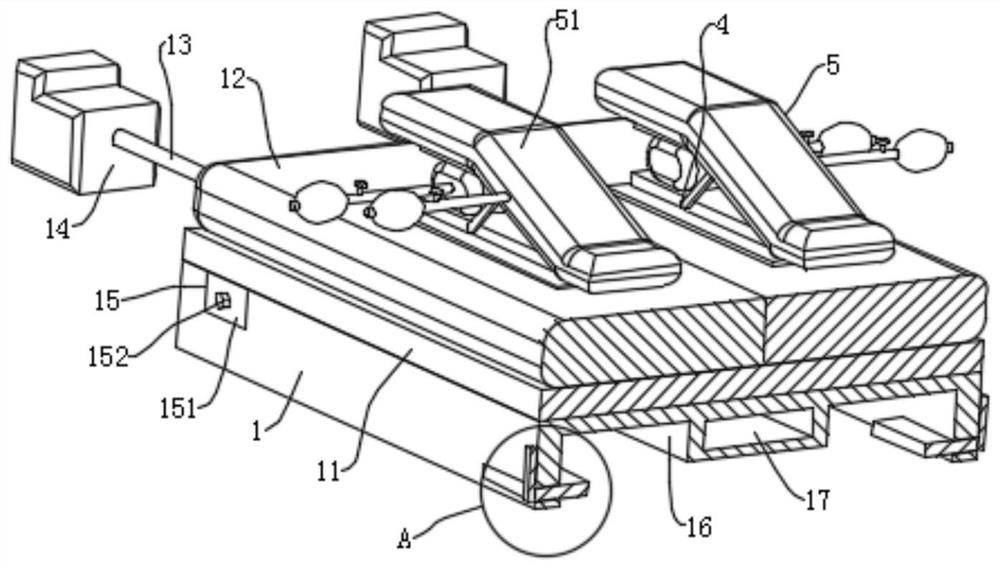

[0051] refer to figure 1 , figure 2 and image 3 , an anti-muscle contracture device for long-term bedridden patients, mainly includes the following parts:

[0052] Disassemble the connected substrate 1 and support plate 11;

[0053] Two reclining airbags 12 are fixed on the top of the support plate 11;

[0054] The first air tubes 13 connected to the two stretch airbags 12, the ends of the two first air tubes 13 are respectively connected with the air pumps 14 for inflating the stretch airbags 12;

[0055] Disassemble the head support air bag assembly 2 connected between the top surfaces of the two lying support air bags 12;

[0056] Disassemble the shoulder expansion airbag assembly 3 connected to the top surface of the two lying airbags 12;

[0057] Disassemble the leg raising assembly 4 connected to the top surface of the two lying airbags 12;

[0058] The leg raising airbag assembly 5 installed on the leg raising assembly 4;

[0059] And the airbag angle adjustmen...

Embodiment 2

[0074] The difference from Example 1 is that the surface of the stretcher airbag 12 is coated with a layer of antifouling coating. Since the stretcher airbag 12 needs to be cleaned with equipment, its surface is easy to become dirty. The surface of the airbag 12 is cleaned, so the surface is coated with an antifouling coating, wherein the antifouling coating is prepared by the following method:

[0075]Take the following raw materials of each component by weight for later use: 80 parts of polytetrafluoroethylene, 60 parts of polypropylene, 60 parts of water-based polyurethane, 40 parts of formaldehyde, 40 parts of polydimethylsiloxane, 10 parts of epoxy resin emulsion, oxidation 10 parts of zirconium fiber, 10 parts of lactic acid, 10 parts of hydroxyethylated fatty amine, 10 parts of ethyl acetate;

[0076] S1. Make antifouling coating pre-preparation solution; stir polytetrafluoroethylene, polypropylene, water-based polyurethane, formaldehyde, polydimethylsiloxane, and epoxy...

Embodiment 3

[0081] The difference from Example 2 lies in the preparation of the antifouling coating on the surface of the stretcher airbag 12, wherein the antifouling coating is prepared by the following method:

[0082] Take the following raw materials of each component by weight for later use: 85 parts of polytetrafluoroethylene, 65 parts of polypropylene, 65 parts of water-based polyurethane, 40 parts of formaldehyde, 40 parts of polydimethylsiloxane, 10 parts of epoxy resin emulsion, oxidation 15 parts of zirconium fiber, 15 parts of lactic acid, 10 parts of hydroxyethylated fatty amine, 10 parts of ethyl acetate;

[0083] S1. Prepare anti-fouling coating pre-preparation solution; stir polytetrafluoroethylene, polypropylene, water-based polyurethane, formaldehyde, polydimethylsiloxane, and epoxy resin emulsion evenly, add to the reaction kettle and heat to 254°C , and then keep warm for 30min;

[0084] S2. Preparation of antifouling coating solution: Cool the antifouling coating pre-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com