Development platform for automatic power station of ships

A technology for developing platforms and ships, which is applied in the system integration field of ship power system control and development platform construction, and can solve the problems of large changes in the hydrodynamic load of propulsion propellers, inability to meet ship power systems, and complex power systems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

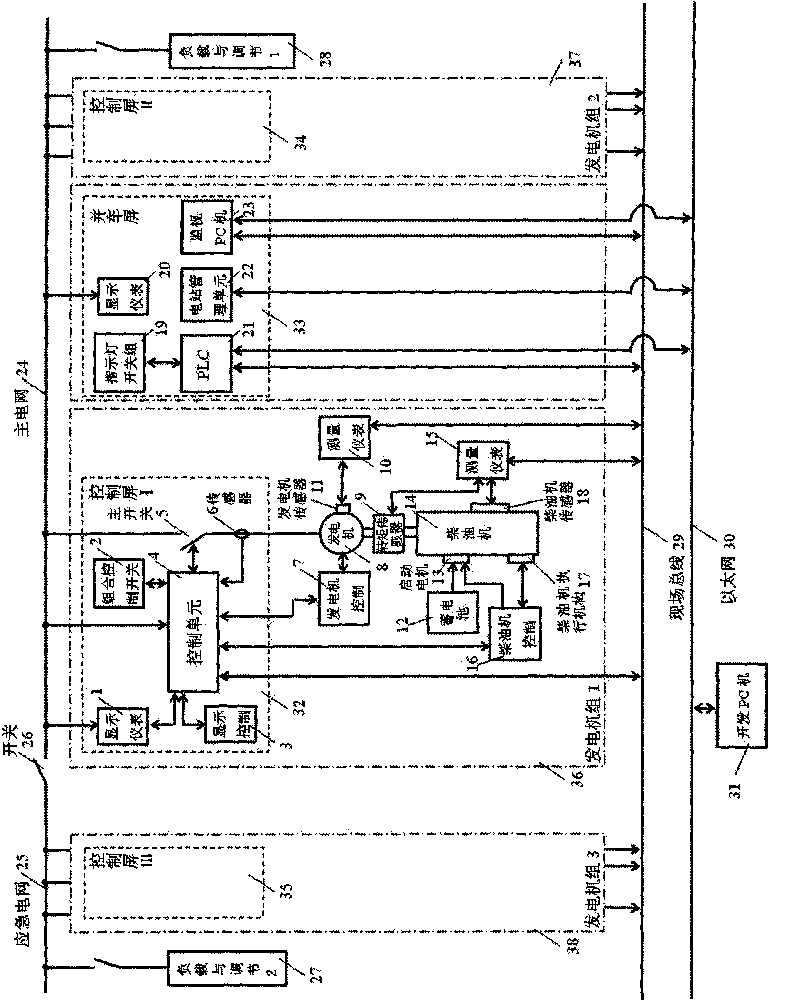

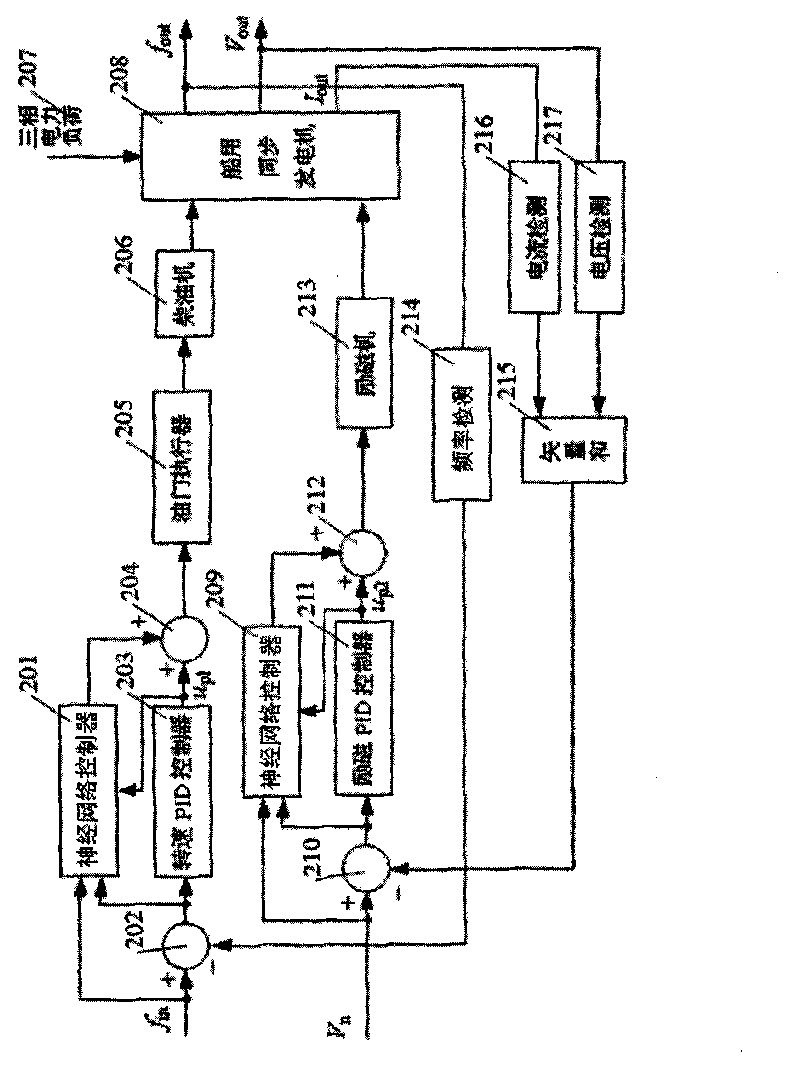

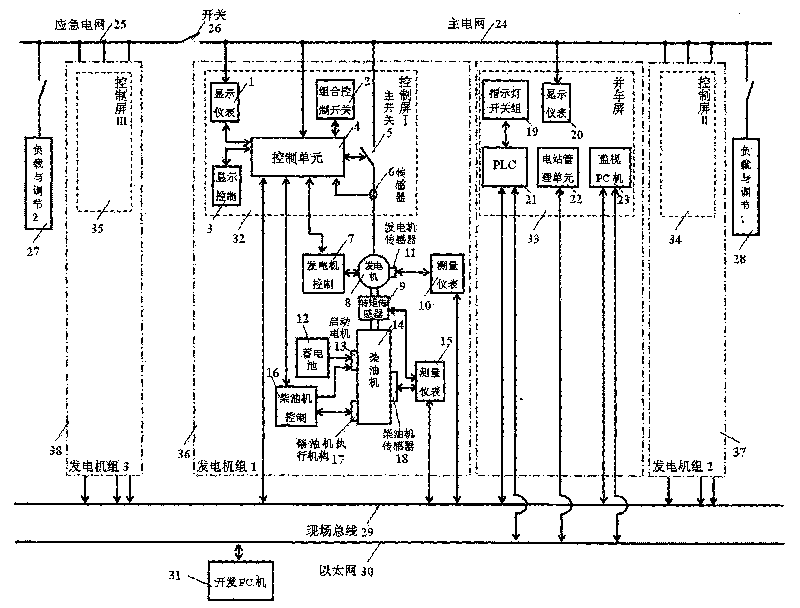

[0041]The specific implementation method is combined with the attached figure 1 and attached figure 2 It is described in two parts, with figure 1 The structure and composition of the system are described, with figure 2 described in the attached figure 1 The control method adopted by the control unit under the structure. (1) The first part (system structure and working process)

[0042] combined with figure 1 , the specific system structure of the present invention will be further described in detail. For system equipment configuration and labels, see figure 1 .

[0043] According to the structural composition diagram of the development platform of the ship automation power station ( figure 1 ), the working process of the device is as follows:

[0044] 1. Overall system

[0045] The ship automation power station development platform consists of 3 marine diesel generator sets, power network and load to form the basic ship power system; the operation of the ship autom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com