Low-end adjusting mechanism for vehicle suspensions

A technology of adjusting mechanism and vehicle suspension, applied in the direction of suspension, elastic suspension, vehicle spring, etc., can solve the problems of non-self-locking, excessive size, drawing, etc., and achieve the improvement of switching time and response time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

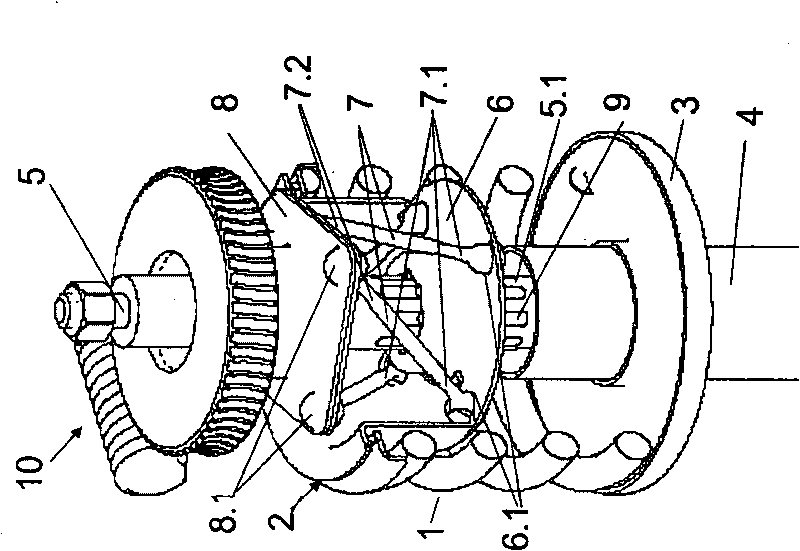

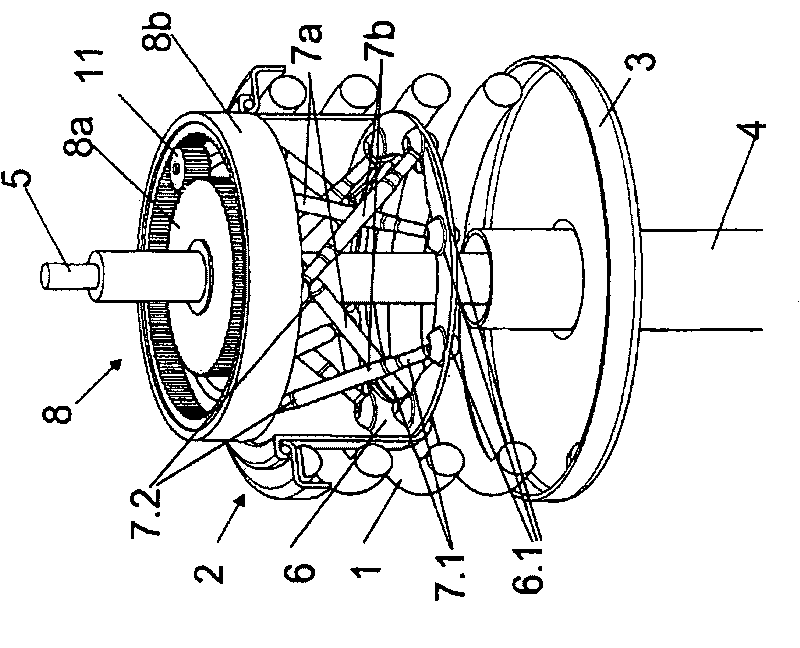

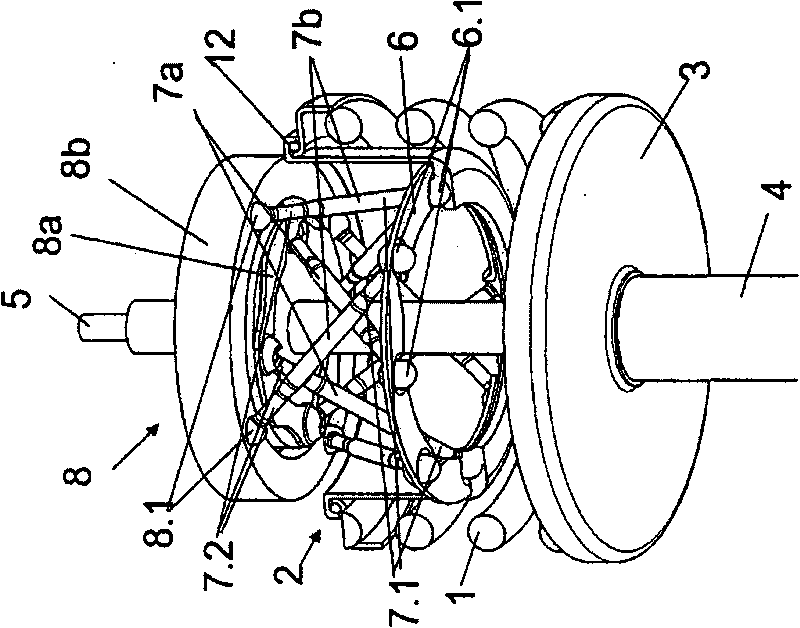

[0028] figure 1 The foot point adjustment mechanism of the spring 1 of the vehicle chassis is briefly shown. Here, a spring 1 in the form of a helical spring is provided. The helical spring is supported by each end on a spring retainer 2 , 3 . A shock absorber 4 is arranged centrally inside the spring 1 (coil spring), which shock absorber includes a piston rod 5 . At its other end, which is not shown, the shock absorber 4 is fastened to the wheel suspension. The first fastening element 6 is axially displaceable and mounted in a rotationally fixed manner and is coupled to the cup-shaped spring washer 2 of the spring 1 (helical spring), and the second fastening element 8 is drivable via a worm gear 10, wherein The coupling element 7 is arranged between the first and the second fixing element 6 , 8 . The spring retainer 2 placed above is pot-shaped. The first fixing element 6 forms the bottom of the basin. A seat 6 . 1 is provided in the first fastening element 6 for the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com