Tundish nozzle quick-change hydraulic control system of continuous casting machine

A technology of hydraulic control system and water inlet, applied in casting equipment, manufacturing tools, casting melt containers, etc., can solve the problems of economic loss, endanger the safety of on-site personnel, product scrapping, etc., and achieve product quality assurance and high movement. Accuracy, the effect of improving the quality of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

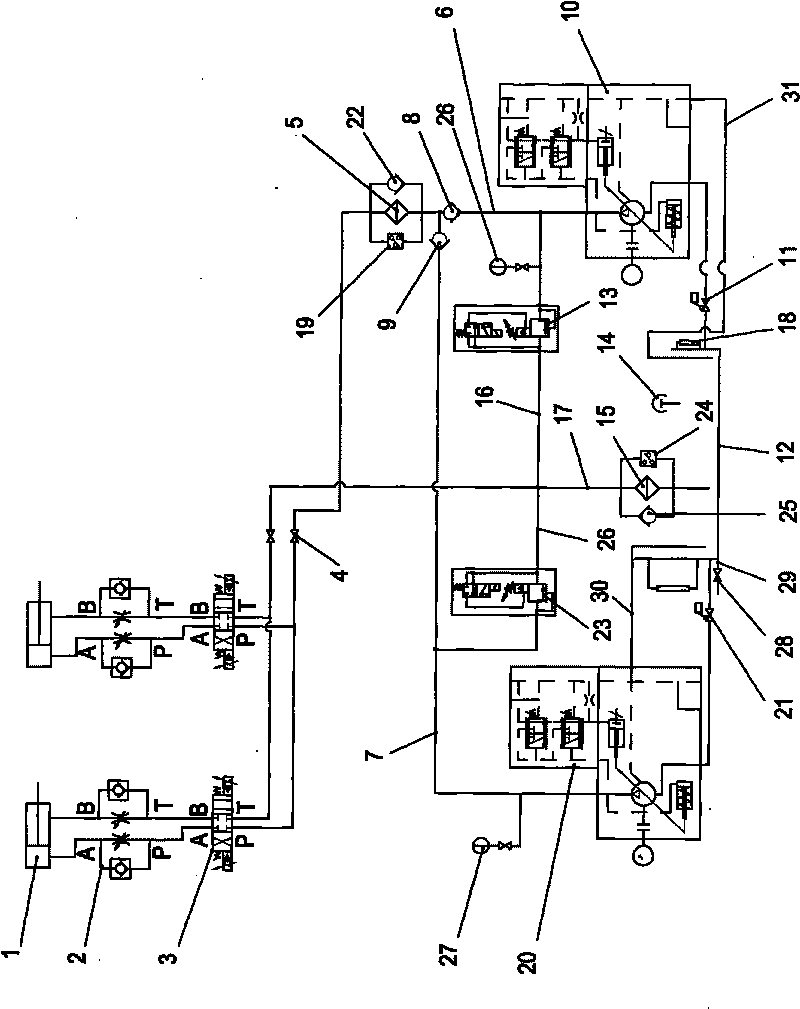

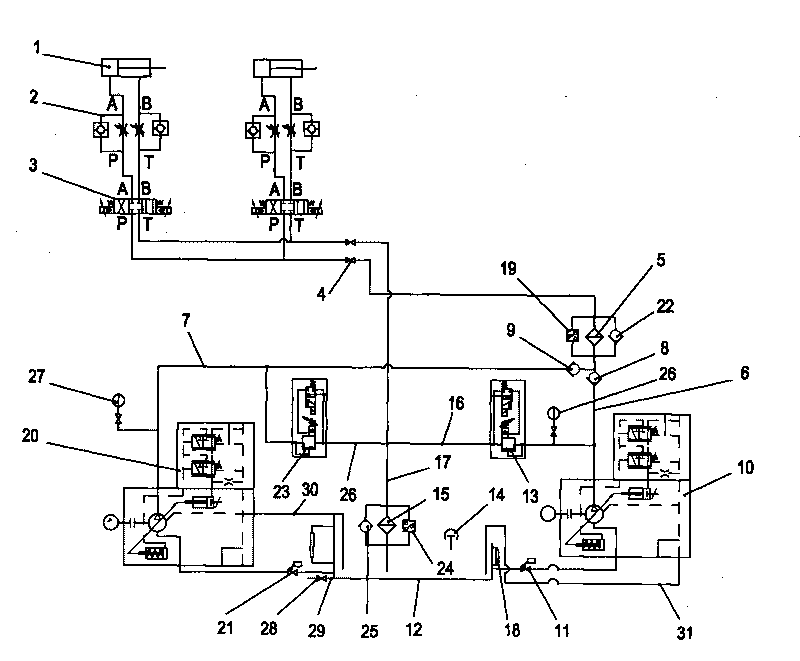

[0011] Such as figure 1 As shown in the upper part of the figure, the continuous casting machine tundish nozzle quick-change hydraulic control system of the present invention includes two driving cylinders 1, and the piston rods of the driving cylinders 1 are connected to the nozzle gates (not shown in the figure), each The propulsion working chamber of the driving cylinder 1 is respectively connected with the oil port A of a double one-way throttle valve 2 through the hydraulic pipeline, and the return working chamber of each driving cylinder 1 is respectively connected with the double one-way throttle valve through the hydraulic pipeline. The oil port B of 2 is connected, and the oil supply port P of each double one-way throttle valve 2 is respectively connected with the oil port A of a three-position four-way solenoid valve 3 through a hydraulic pipeline, and each double one-way throttle valve The oil drain port T of the valve 2 communicates with the oil port B of the three...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com