Coal water slurry process burner with long service life and method for manufacturing same

A process burner and processing method technology, which is applied in the direction of granular/powdered fuel gasification, etc., can solve the problems of high repair frequency and short service life, and achieve the effect of increasing start-up time, reducing production cost, and reducing the number of parking maintenance times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

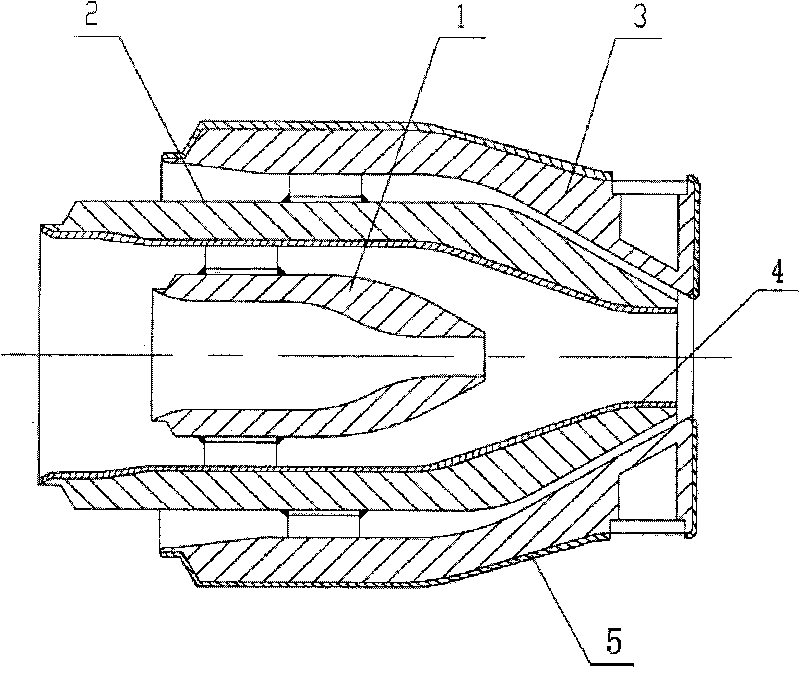

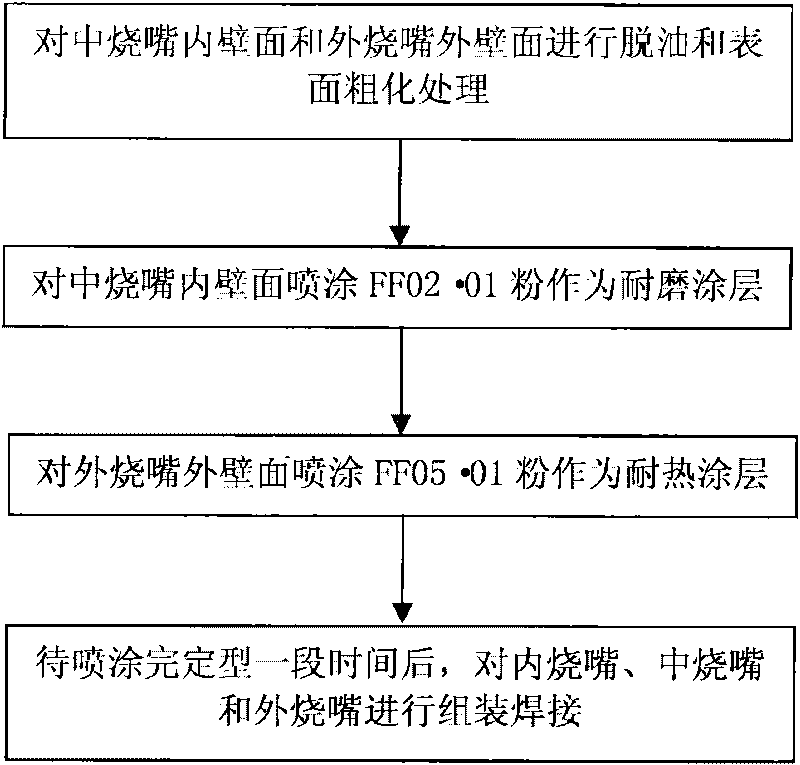

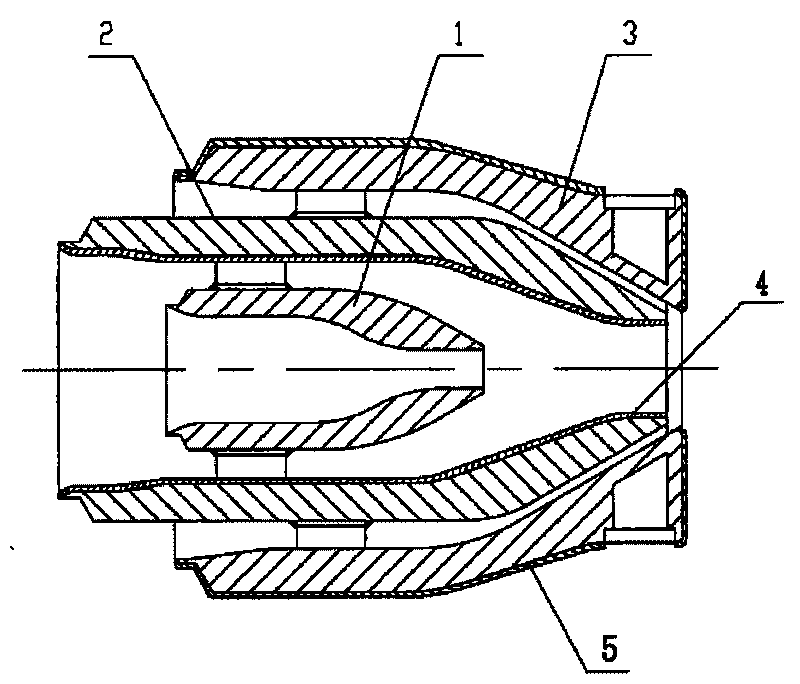

[0022] The structure of the coal-water slurry process burner provided by the present invention with long cycle service life is as follows: figure 1 As shown, it consists of an inner burner 1, a middle burner 2 and an outer burner 3 coaxially sleeved with a streamlined front end. The inner burner 1, the middle burner 2 and the outer burner 3 are fixedly connected by a welding process. Wear-resistant coatings are sprayed on the inner wall surface of the middle burner 2 and the outer wall surface of the outer burner 3 respectively.

[0023] The coating 4 on the inner wall of the middle burner is made of tungsten-based alloy powder. The components and mass percentages of FF02·01 tungsten-based alloy powder are: Co23-28%, C4-10%, W62-70% ; The thickness of the coating 4 on the inner wall of the middle burner is 0.2mm-0.6mm, and the optional range is 0.2m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com