High-strength steel plate for super-thick 80,000-ton large-scale forging press brackets, and production method thereof

A high-strength steel plate and die forging press technology, which is applied in the field of steel smelting, can solve the problems of unreachable thickness and strength of the finished steel plate, and achieve the effects of uniform composition of the steel plate, good low-temperature toughness, good shape and surface quality of the steel plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

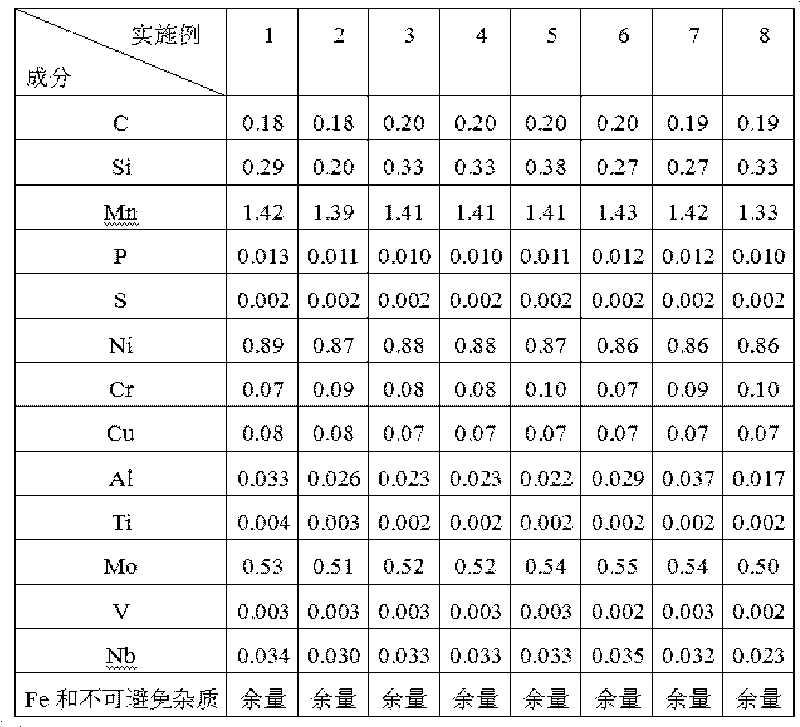

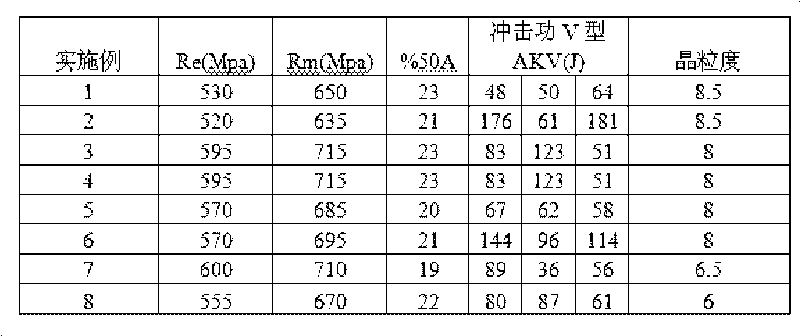

[0030] The high-strength steel plate used for the support of the large-scale die forging press with an extra-thickness of 80,000 tons is shown in Table 1.

[0031] A method for producing a high-strength steel plate for a support of an extra-thick 80,000-ton large die forging press includes the following steps:

[0032] (1) The molten steel containing the mass percentages shown in Table 1 is smelted in an electric furnace and sent to an LF refining furnace for refining. During refining, 300 meters of Al wire is fed, and the ladle temperature is 1600°C, C≤0.16%, P≤0.010%. Vacuum treatment in VD furnace, adding SiCa blocks before vacuuming, the amount of SiCa is 0.5kg / ton of steel, the vacuum degree is 60Pa, the vacuum is kept for 20 minutes, and then the vacuum is broken, which solves the problem of deoxidation of molten steel by Al wire alone and non-metallic inclusions in steel The phenomenon of high content ensures the purity of steel;

[0033] (2) After billet drawing, off-...

Embodiment 2

[0040] The high-strength steel plate used for the support of the large-scale die forging press with an extra-thickness of 80,000 tons is shown in Table 1.

[0041] A method for producing a high-strength steel plate for a support of an extra-thick 80,000-ton large die forging press includes the following steps:

[0042] (1) The molten steel containing the mass percentages shown in Table 1 is smelted in an electric furnace, refined in an LF refining furnace, fed with 500 meters of Al wire during refining, and placed in a VD furnace when the ladle temperature is 1800°C, C≤0.16%, and P≤0.010%. Vacuum treatment, adding SiCa blocks before vacuuming, the amount of SiCa is 1kg / ton of steel, the vacuum degree is 66.16Pa, the vacuum is kept for 30 minutes, and then the vacuum is broken;

[0043] (2) After billet drawing, off-line stacking is slowly cooled for 20 hours, cleaned with temperature, and transferred to electroslag remelting to make steel ingots. The melting rate during electr...

Embodiment 3

[0050] The high-strength steel plate used for the support of the large-scale die forging press with an extra-thickness of 80,000 tons is shown in Table 1.

[0051] A method for producing a high-strength steel plate for a support of an extra-thick 80,000-ton large die forging press includes the following steps:

[0052] (1) The molten steel containing the mass percentages shown in Table 1 is smelted in an electric furnace, refined in an LF refining furnace, fed with 400 meters of Al wire during refining, and placed in a VD furnace when the ladle temperature is 1800°C, C≤0.16%, and P≤0.010%. Vacuum treatment, add SiCa block before vacuum, the amount of SiCa is 1kg / ton of steel, vacuum degree 50Pa, keep vacuum for 20 minutes, and then break the vacuum;

[0053] (2) After billet drawing, off-line stacking is slowly cooled for 20 hours, cleaned with temperature, and transferred to electroslag remelting to make steel ingots. The melting rate during electroslag remelting is 20Kg / min,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com