Photoelectric double-edge bearing static balance measurer and measuring method

A measurement method and double-knife-edge technology, applied in static/dynamic balance testing, measuring devices, instruments, etc., can solve problems such as low automation, low measurement accuracy, and short service life, and achieve high precision, sensitivity, and measurement accuracy High and long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

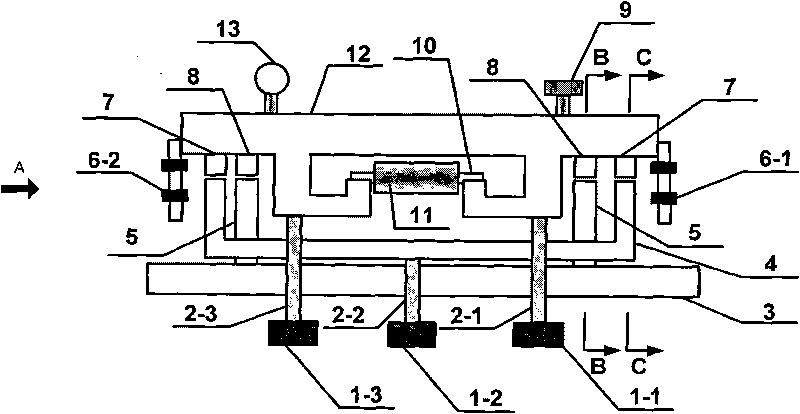

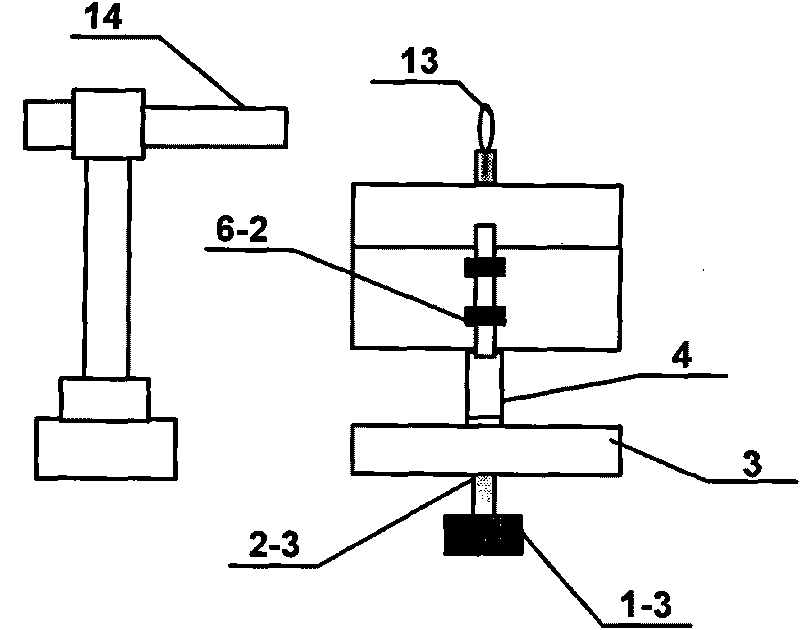

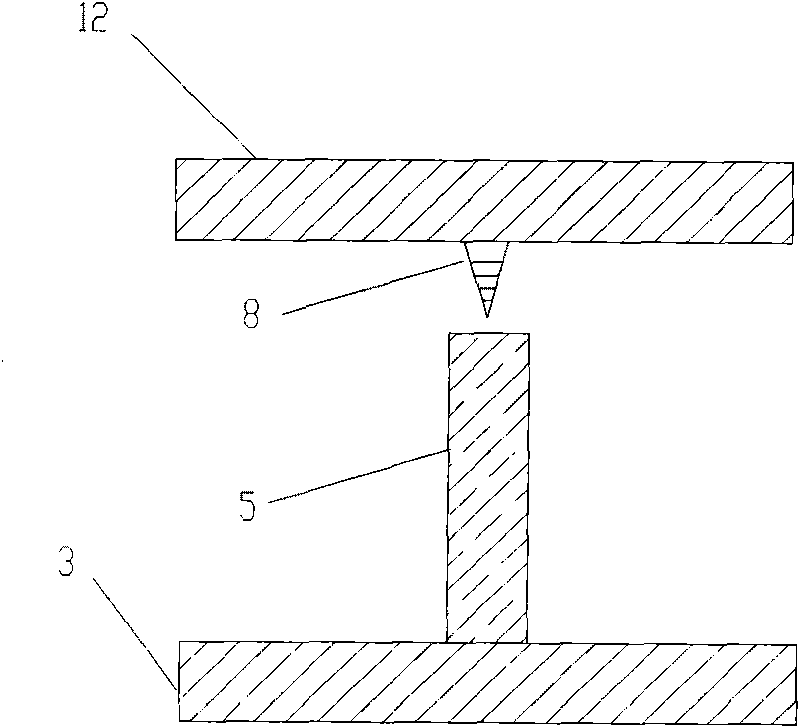

[0013] Specific implementation mode one: combine figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 Description of this embodiment, the photoelectric double-knife-edge static balance measuring instrument includes a first lifting mechanism 1-1, a second lifting mechanism 1-2, a third lifting mechanism 1-3, a first pillar 2-1, a second Pillar 2-2, third pillar 2-3, base 3, a pair of outer knife holders 4, a pair of inner knife holders 5, a pair of thick knife edges 7, a pair of thin knife edges 8, support 10, bracket body 12, Measuring mirror 13 and photoelectric collimator light pipe 14, the first pillar 2-1, the second pillar 2-2 and the third pillar 2-3 are respectively arranged on the first lifting mechanism 1-1, the second lifting mechanism 1 -2 and the third lifting mechanism 1-3, the first pillar 2-1 and the third pillar 2-3 are symmetrically supported on the lower end of the bracket body 12, and the second pillar 2-2 is supported on the center of the outer kni...

specific Embodiment approach 2

[0014] Specific implementation mode two: combination figure 1 , figure 2 and image 3 Describe this embodiment, the difference between this embodiment and specific embodiment 1 is that the photoelectric double-knife-edge support static balance measuring instrument also includes a calibration frame 9, a first balance weight 6-1 and a second balance weight 6-2, so The two balance weights are symmetrically arranged on the left and right ends of the bracket body 12 , and the calibration frame 9 is arranged on the upper surface of the bracket body 12 .

[0015] Before placing the rotor 11 under test, the center of gravity of the bracket 12 needs to be adjusted, and the function of the two balance weights adjusts the position of the center of gravity of the bracket 12 to the center of the bracket 12 .

[0016] The function of the calibration frame 9 is to establish the relationship between the static unbalance and the deflection angle of the bracket body 12 .

specific Embodiment approach 3

[0017] Specific implementation mode three: combination Figure 7 , Figure 8 , Figure 9 , Figure 10 and Figure 11 Describe this embodiment, the difference between this embodiment and specific embodiment 1 or 2 is that the photoelectric double knife-edge support static balance measuring instrument also includes three lifting assemblies 15, and each of the lifting assemblies 15 is supported by a support plate 15 -2 and three supports 15-1, the three lifting components 15 are respectively arranged on the upper end of the first pillar 2-1, the upper end of the second pillar 2-2 and the upper end of the third pillar 2-3, the three supports 15 -1 Two pairs are equidistantly arranged on the support plate 15-2, the three supports 15-1 are V-shaped support, plane support and conical support respectively, the part of the bracket body 12 in contact with the V-shaped support or the conical support Corresponding V-shaped protrusions or conical protrusions are provided so that the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com