Polarizing film locking unit on front frame of liquid crystal display

A technology for locking devices and liquid crystal display panels, which is applied in the directions of instruments, optics, nonlinear optics, etc., can solve problems such as locking device shaking, film scrapping, and slanting, and achieve the effect of reducing the number of scrapping and enhancing safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manners of the present invention will be described in further detail below with reference to the accompanying drawings. Throughout the description, like reference numerals refer to like parts.

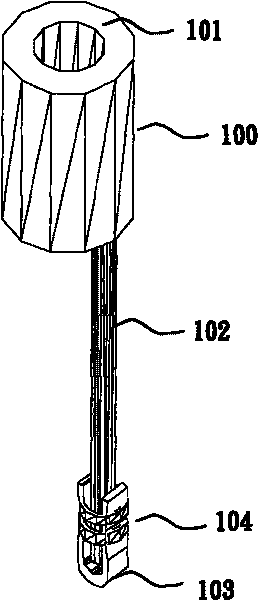

[0020] Figure 1a A schematic diagram of a locking device kit is shown. refer to Figure 1a , the locking device kit includes: an integral component 100 of a sleeve and an insulating rod, a sleeve 101 , an insulating rod 102 , elastic terminals 103 and nylon cable ties 104 . Wherein, the sleeve 101 and the insulating rod 102 are fixedly connected, for example, integrally formed. The end of the insulating rod 102 away from the sleeve 101 and the elastic terminal 103 are fixedly connected with a nylon cable tie 104. The insulating rod 102 is made of a cylindrical plastic material, and the elastic terminal 103 can be a rubber strip, a plastic strip, etc. Elastic material.

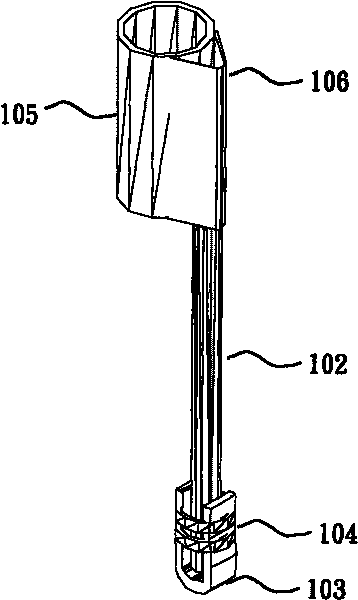

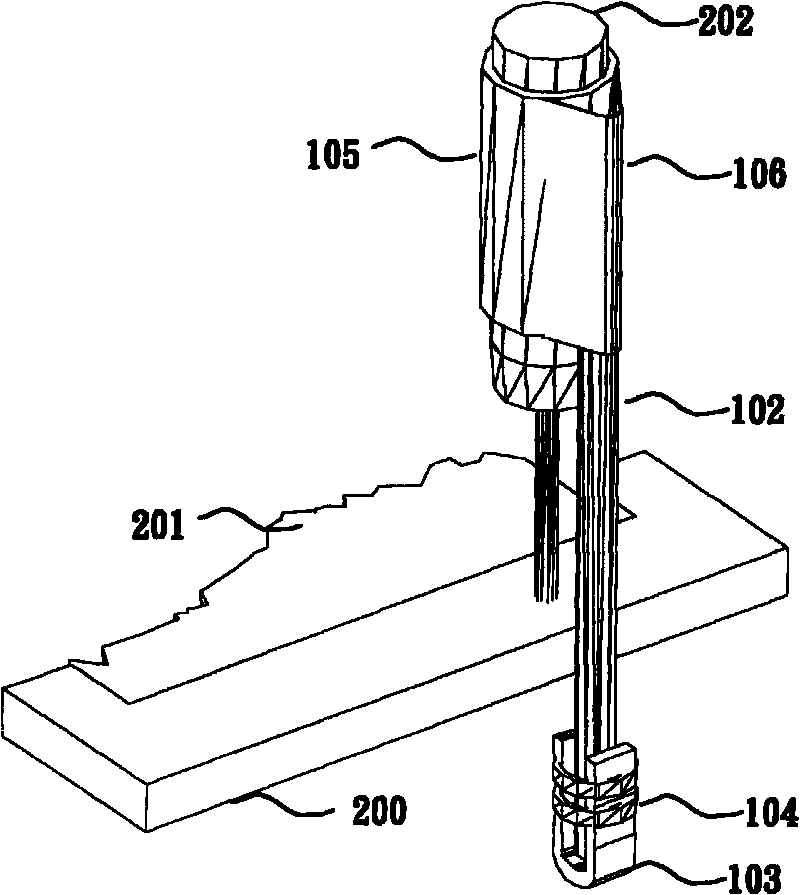

[0021] Figure 1b A schematic diagram of another locking device kit is shown....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com