Method for producing dress one-piece flow

A production method and single-piece flow technology, applied in the field of garment production, can solve the problems that the production department cannot correctly formulate the production plan, cannot accurately calculate the completion date in advance, and the quality problems are not easy to find in time, so as to improve the output straight-through rate and process The effect of smooth, short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

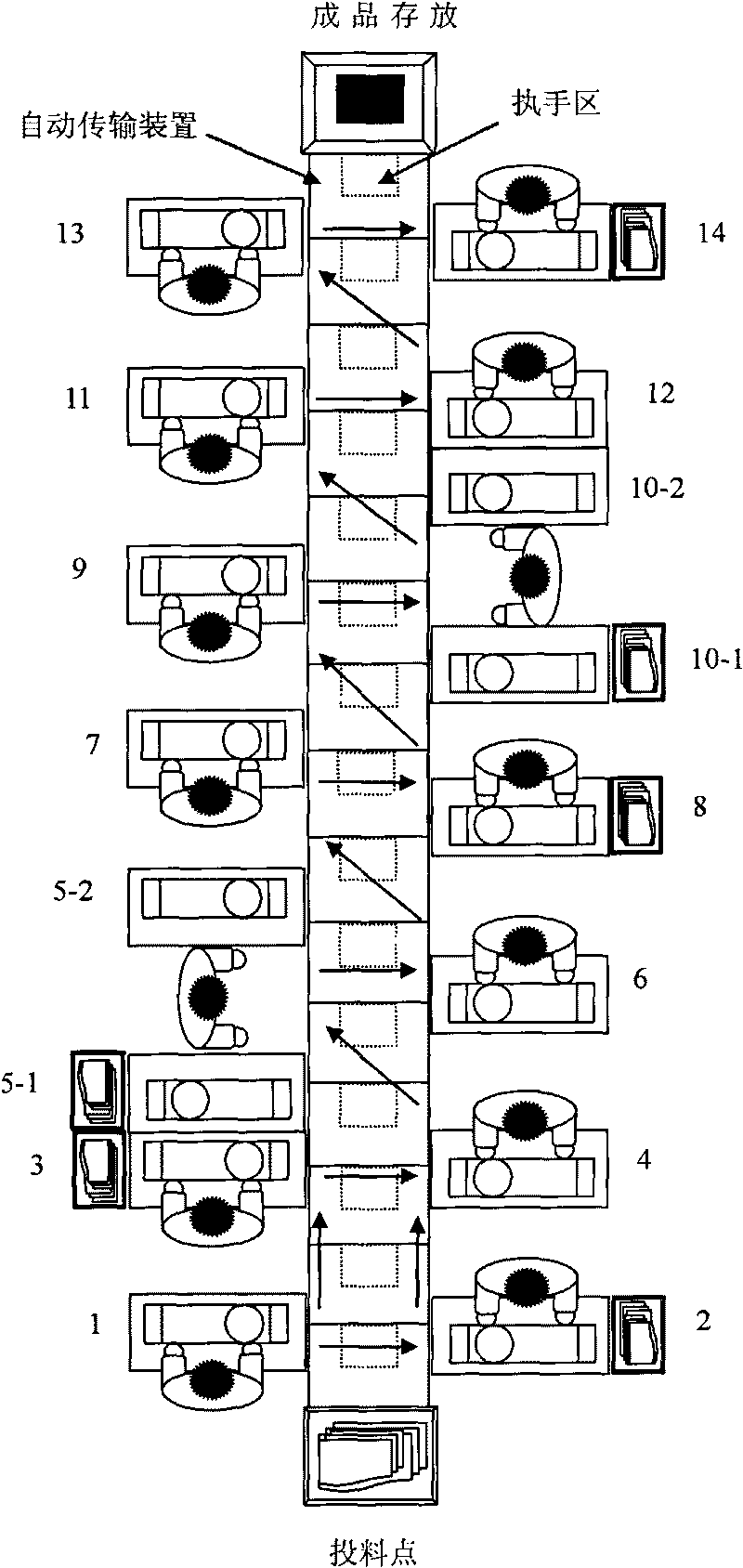

[0043] like figure 1 As shown, the present embodiment takes the production of sports pants as an example, and adopts the following production method:

[0044] a) Configure an automatic transmission device: This embodiment adopts an automatic transmission belt as the automatic transmission device. The transmission belt can continuously circulate in a certain direction, and the movement rhythm of the transmission belt is adjustable. Before production, the movement rhythm of the conveyor belt should be preset first, and then further fine-tuned according to the production situation.

[0045] b) Division of workstations on the automatic transmission device: The equal-spaced workstations are divided on the conveyor belt with paint or tape.

[0046] c) Divide the handle area on the station grid: divide the handle area on each station grid.

[0047] d) Configure station machines on both sides of the automatic transmission device: according to the formulated production process and proc...

Embodiment 2

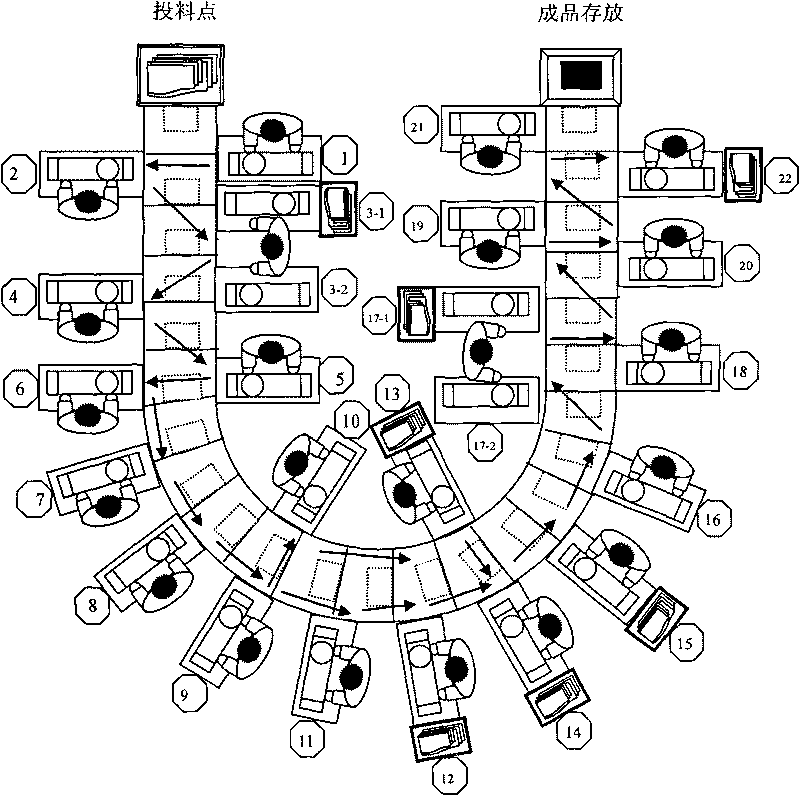

[0061] like figure 2 As shown, this embodiment takes the production of men's sweatshirts as an example. The difference from Example 1 is that the automatic conveyor belt is placed in a "U" shape, the station machines are arranged in a "U" shape at the same time, and the process of producing garments is changed accordingly. figure 2 Among them, the number of "1"-"22" is the number of the processing station. Table 2 shows the types and quantities of machines corresponding to each process and processing station in this embodiment. Among them: 3-1 processing station, 12 processing station, 13 processing station, 14 processing station, 15 processing station, 17-1 processing station, 22 processing station need to be attached Material feeding.

[0062]

[0063]

[0064] Table 2

[0065] Such single-piece flow production can not only make reasonable use of the production site, but also can greatly reduce the movement caused by the communication, positioning or transfer bet...

Embodiment 3

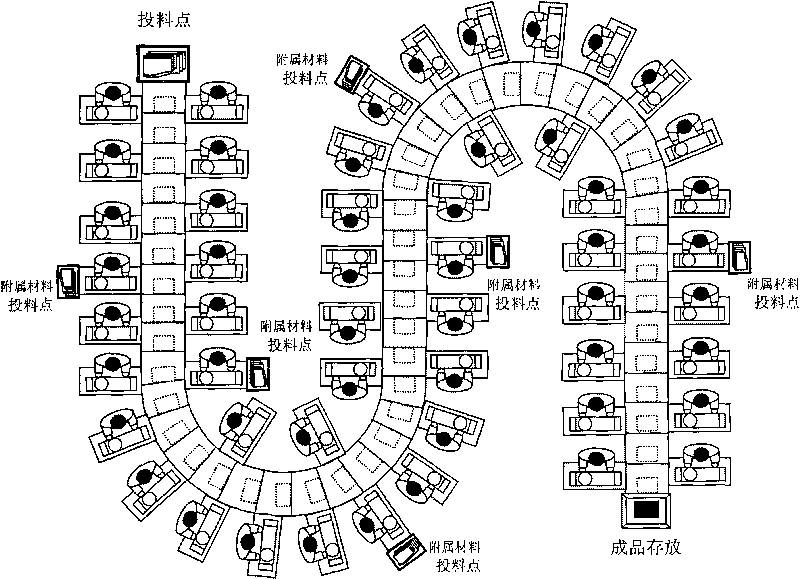

[0067] It is easy to think that the automatic conveyor belt can also be placed in an "S" shape, such as image 3 As shown, the orientation and working methods of personnel, such as sitting and standing, can also be formulated according to the actual situation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com