Method for centrifugally separating oil soluble nano particles by organic density gradient

A nanoparticle and density gradient technology is applied in the field of advanced nanomaterial separation technology to achieve a wide range of separation sizes, simple purification and good separation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) First, use 10mg / ml of HAuCl 4 The oleylamine solution was reacted with 10ml cyclohexane at 80°C for 10h to generate a cyclohexane colloidal solution of about 1mg / ml Au nanoparticles.

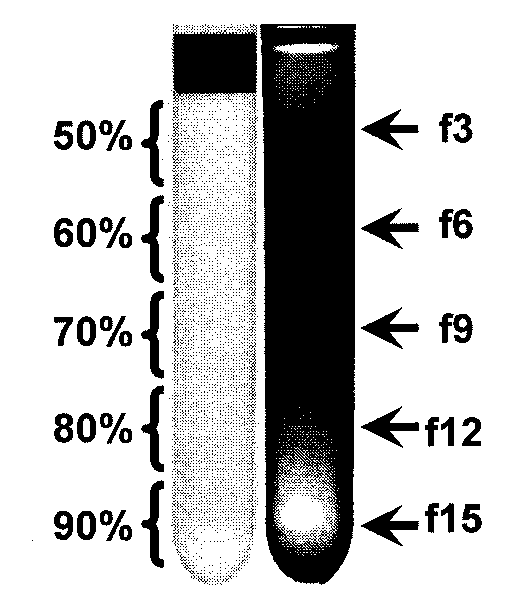

[0026] (2) Make a density gradient: use carbon tetrachloride and cyclohexane to prepare 50%, 60%, 70%, 80%, and 90% carbon tetrachloride-cyclohexane solutions by volume. Starting from 90%, gradually take 2ml of the solution and gently add it to the centrifuge tube to prepare a gradient solution.

[0027] (3) Add 0.4 ml cyclohexane dispersion of Au nanoparticles to the gradient liquid.

[0028] (4) 15°C, 100×10 -6 Atmospheric pressure, 25000rpm, high-speed centrifugation under the condition of 10min.

[0029] (5) Divide the centrifuged mixture into 16 parts, and suck it out from the top with a pipette. Finally, Au nanoparticle dispersions with different sizes were obtained.

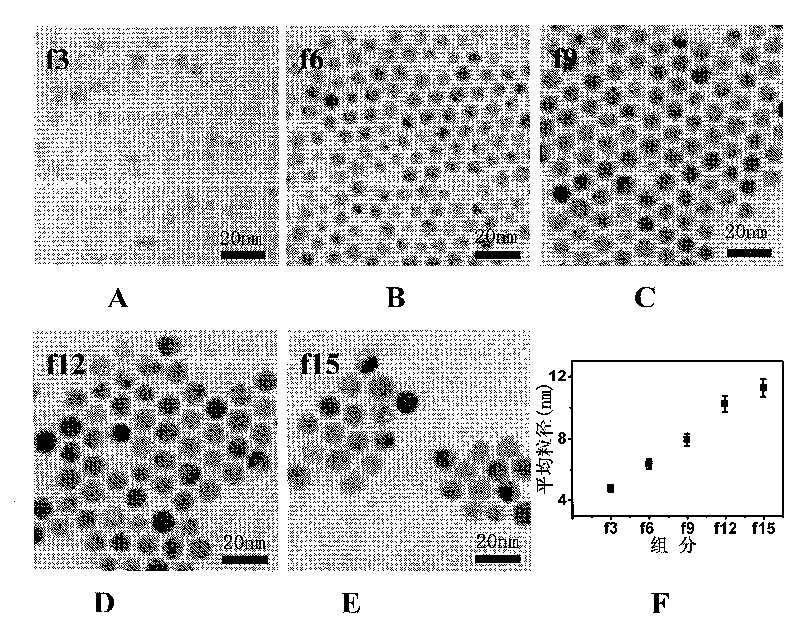

[0030] For separation results, see figure 1 ,2.

[0031] Change the separation conditions, change the de...

Embodiment 2

[0033] (1) First, use 10mg / ml of HAuCl 4 5ml of oleylamine solution was reacted with 5ml of cyclohexane at 50°C for 72h to generate a colloidal solution of about 5mg / ml Au nanowires / nanoparticles.

[0034] (2) Preparation of density gradient: use carbon tetrachloride and cyclohexane to prepare 50%, 60%, 70%, 80%, 90% carbon tetrachloride-cyclohexane solutions by volume. Starting from 90%, gradually take 2ml of the solution and gently add it to the centrifuge tube to prepare a gradient solution.

[0035] (3) Add 0.4 ml of the synthesized Au nanowire / nanoparticle colloidal solution to the gradient solution.

[0036] (4) 15°C, 100×10 -6 Atmospheric pressure, 30000rpm, high-speed centrifugation under the condition of 18min.

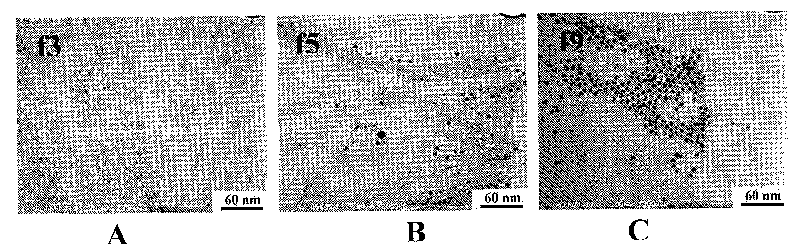

[0037] (5) Divide the centrifuged mixture into 26 parts, and suck it out from the top with a pipette. Finally, nanoparticle dispersions with different sizes and shapes are obtained.

[0038] For separation results, see image 3

[0039] Change the sepa...

Embodiment 3

[0041] (1) First, take 2ml of Fe wrapped in oleic acid 3 o 4 The cyclohexane colloidal solution of nanoparticles was ultrasonicated for 4 hours, and the water was changed every half hour.

[0042] (2) Make a density gradient: use carbon tetrachloride and cyclohexane to prepare 50%, 60%, 70%, 80%, and 90% carbon tetrachloride-cyclohexane solutions by volume. Starting from 90%, gradually take 2ml of the solution and gently add it to the centrifuge tube to prepare a gradient solution.

[0043] (3) Add 0.4ml of Fe 3 o 4 A colloidal solution of nanoparticles is added to the gradient.

[0044] (4) 15°C, 100×10 -6 Atmospheric pressure, 35000rpm, high-speed centrifugation under the condition of 35min.

[0045] (5) Divide the centrifuged mixture into 20 parts, and suck it out from the top with a pipette. Finally, Fe with different sizes is obtained 3 o 4 nanoparticle dispersion.

[0046] For separation results, see Figure 4

[0047] Change the separation conditions, change...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com