Rubbish compressor

A garbage compressor and garbage technology, which is applied in the field of compressors for collecting, compressing and processing garbage in garbage transfer stations. It can solve the problems that the main machine cannot be moved, the capital investment increases, and the garbage is easy to be plugged in, so as to increase the amount of garbage processed and eliminate safety issues. Hidden dangers, manpower and time saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

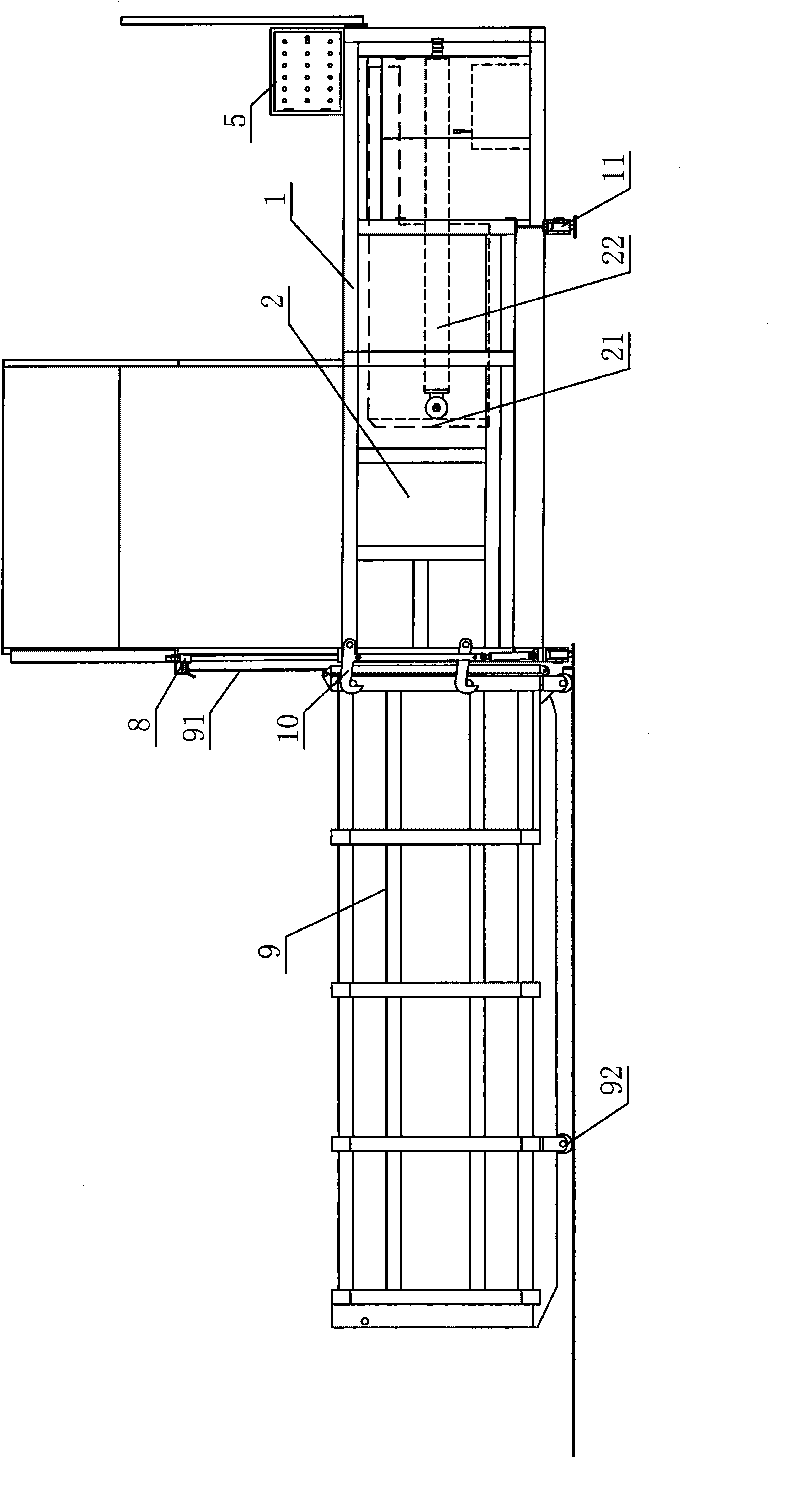

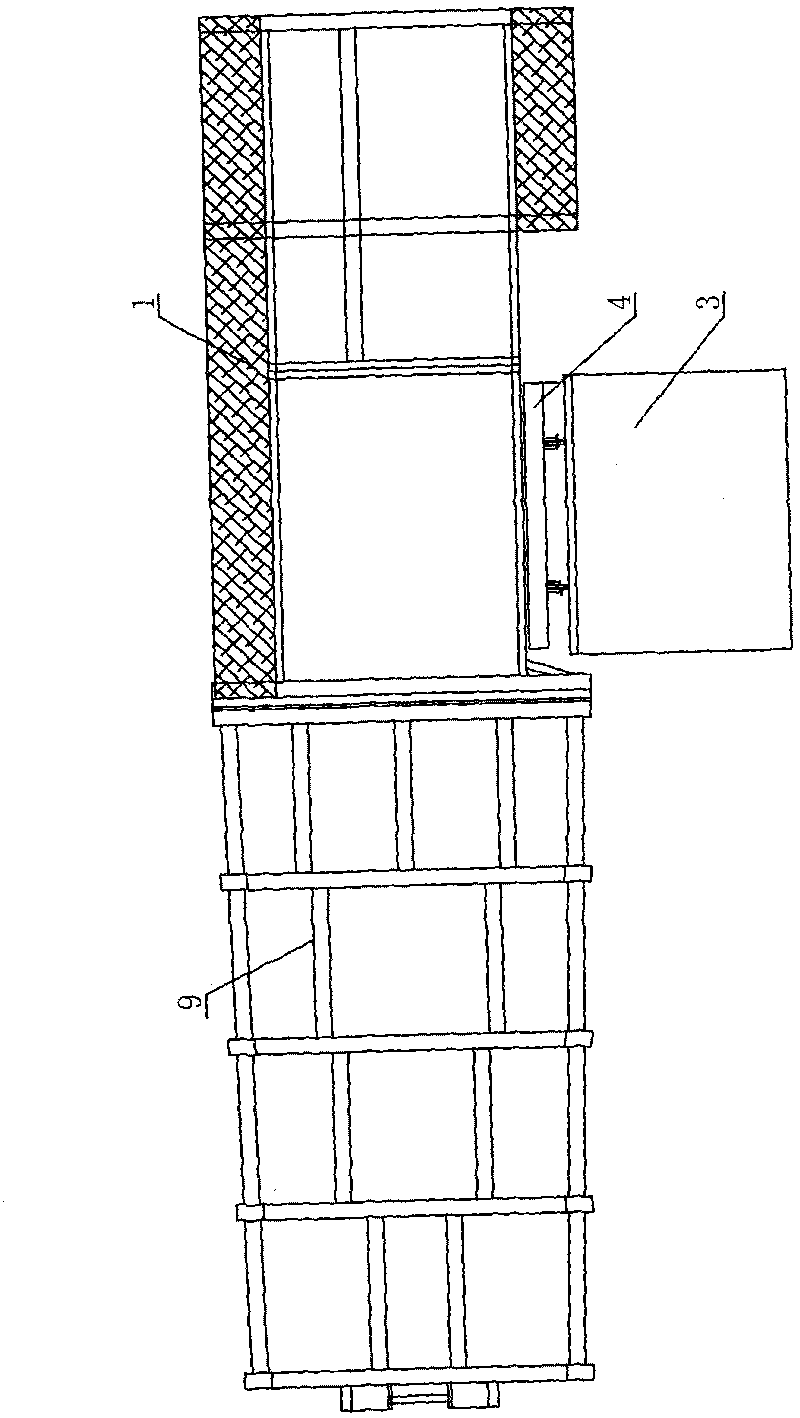

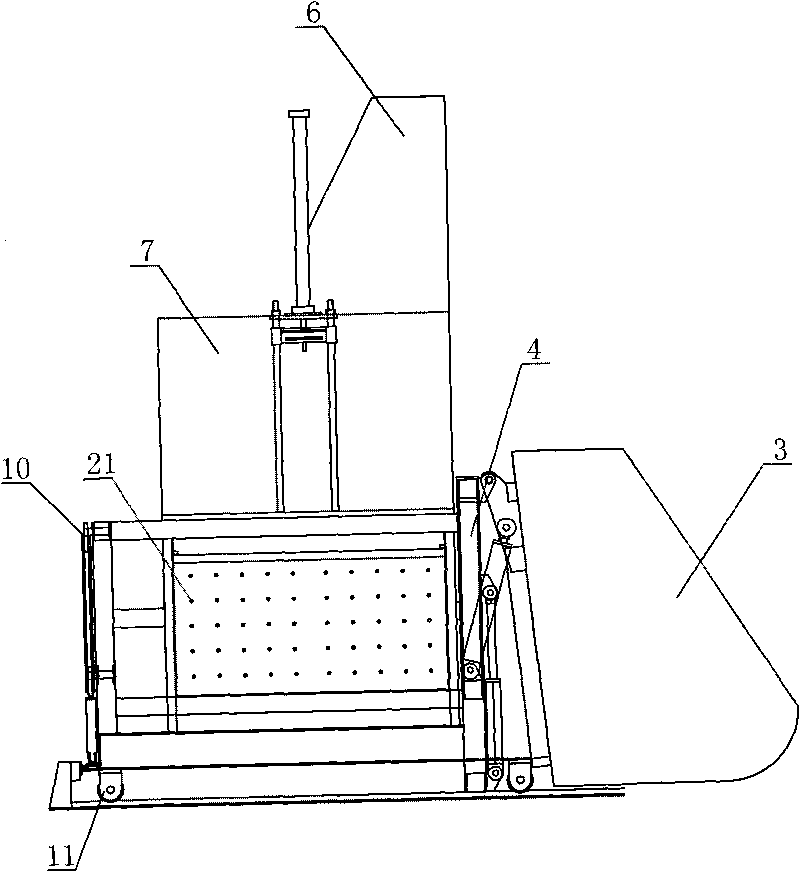

[0019] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0020] like Figure 1 to Figure 6 A kind of garbage compressor shown, comprises movable compression host 1, movable garbage compression container 9 and electric control device 5, and compression host 1 comprises the box body 2 that holds garbage and the movable box body 2 that can compress the garbage in box body 2. Move the pressing plate 21, the pressing plate 21 is provided with a sewage diversion mesh, the compression host 1 also has a main oil cylinder 22, the base of the main oil cylinder 22 is installed on one end of the casing 2, and the piston rod of the main oil cylinder 22 is connected to the pressing plate 21. The container 9 is arranged at the ot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com