Heat accumulation and heat slow-release composite floor module

A composite floor, heat buffer technology, applied in central heating, can solve the problem of the floor has no heat storage and heat slow release function, can not effectively use the heat source, poor heat storage performance, etc., to improve the utilization rate and added value, broad development Utilize the foreground, the effect of small heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

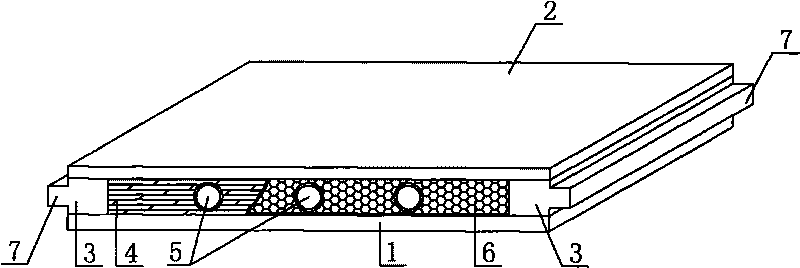

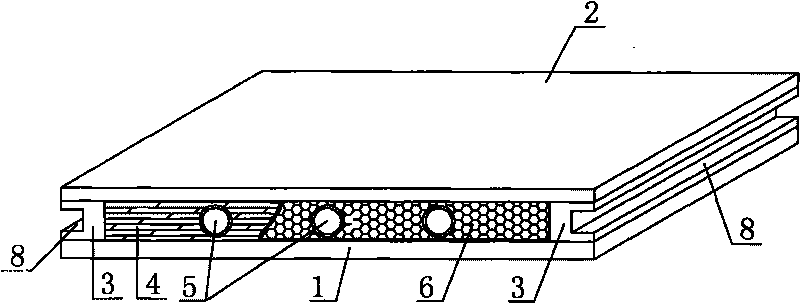

[0034] Such as figure 1 with figure 2 As shown, the heat storage and heat sustained release composite floor module of the present invention has a thermal insulation bottom plate and a bamboo floor surface layer 2; between the thermal insulation bottom plate 1 and the bamboo floor surface layer 2 and on both sides of the module There are wooden squares 3 respectively, and the wooden squares 3 are provided with a connecting structure for connecting with adjacent modules; the two ends of the modules are respectively provided with a thermal insulation floor 1 and a bamboo floor surface 2 End plate 4; a through bamboo tube 5 is installed between the thermal insulation bottom plate 1 and the bamboo floor surface 2 and the two ends of the round bamboo tube 5 are respectively placed in the corresponding circular holes of the two end plates 4, A phase change heat storage material 6 is also filled between the thermal insulation bottom plate 1 and the bamboo floor surface layer 2.

[0035]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com