A new type of side-lit backlight module assembly structure

A backlight module and assembly structure technology, applied in optics, nonlinear optics, instruments, etc., can solve the problems of wavy deformation, thermal deformation, thick film material, uneven force, etc., to increase the overall strength, save space, The effect of preventing deformation moiré

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention provides a novel side-lit backlight module assembly structure, which can effectively overcome the thicker film thickness and poor stress caused by fixing various optical film materials in the existing large-size backlight module. Unfavorable problems such as uniform wavy deformation and heat deformation, in order to make the purpose, technical solution and advantages of the present invention clearer and clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

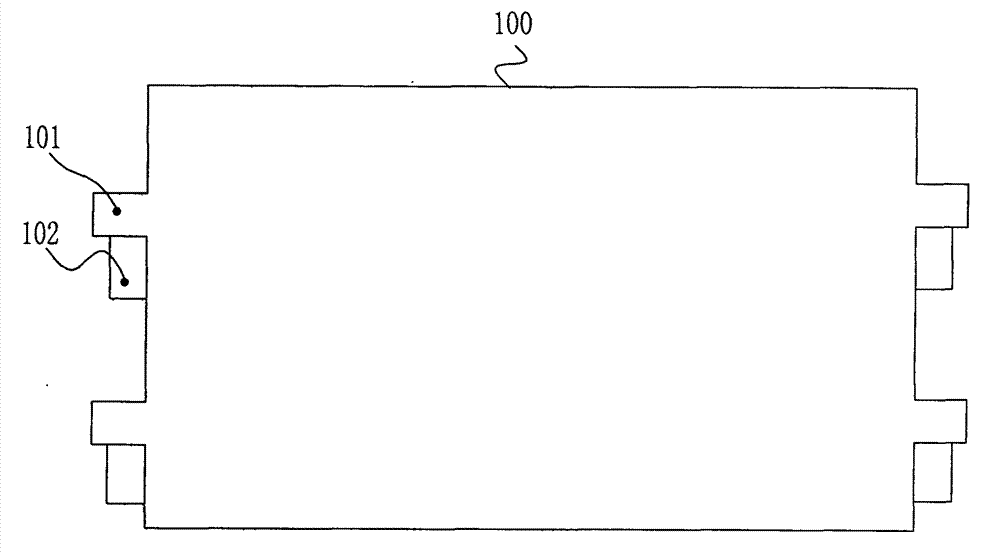

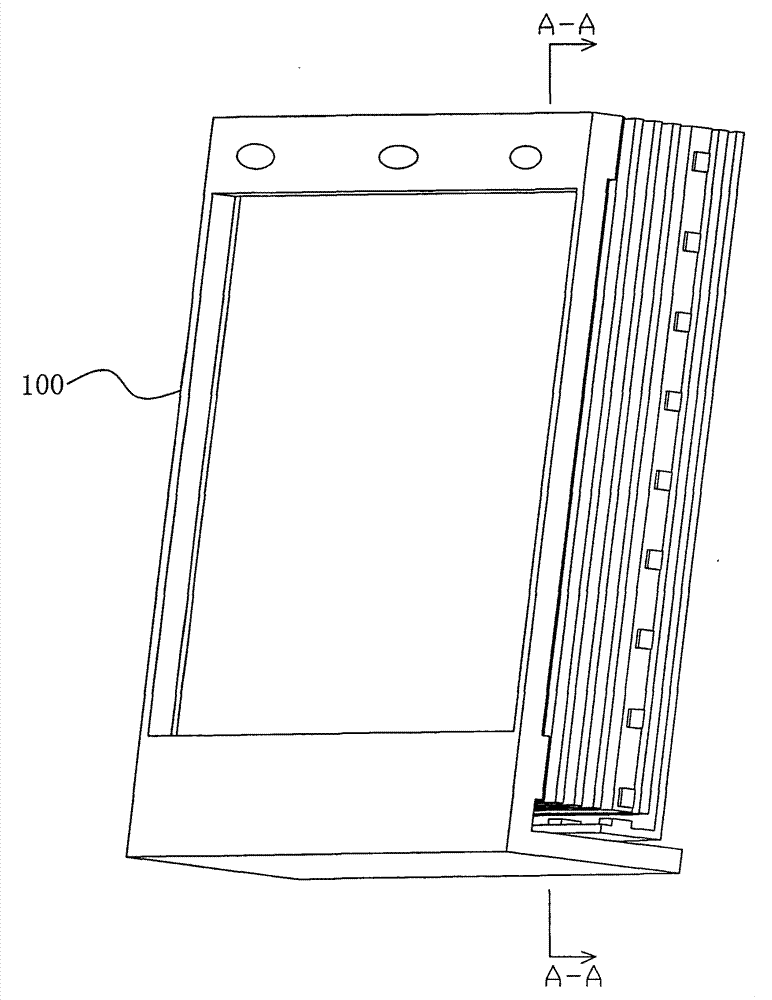

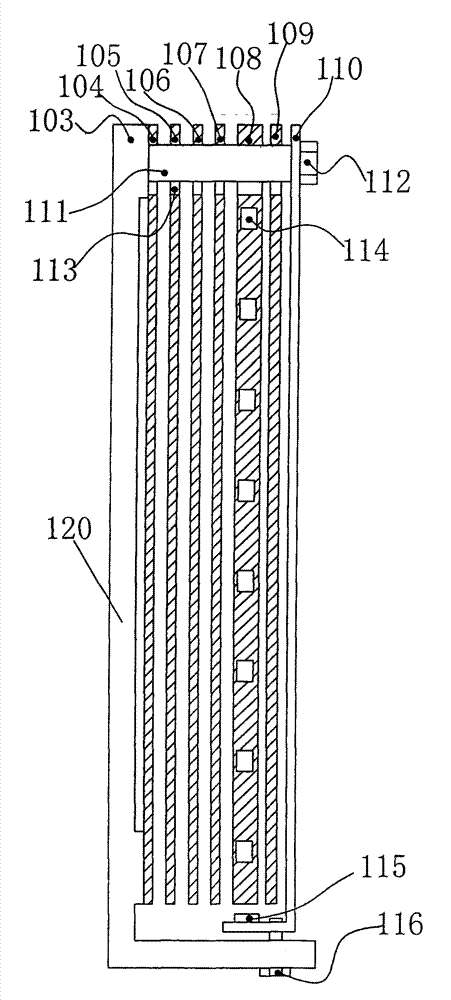

[0024] A novel side-light backlight module assembly structure provided by the implementation of the present invention, such as figure 2 and image 3 As shown, the side-lit backlight module assembly structure 100 includes a liquid crystal panel 104 sequentially assembled on the frame 120, a first diffusion film 105, a prism sheet 106, and a second diffusion film 107 according to the viewing direction of the human eye. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com