Solar cell module

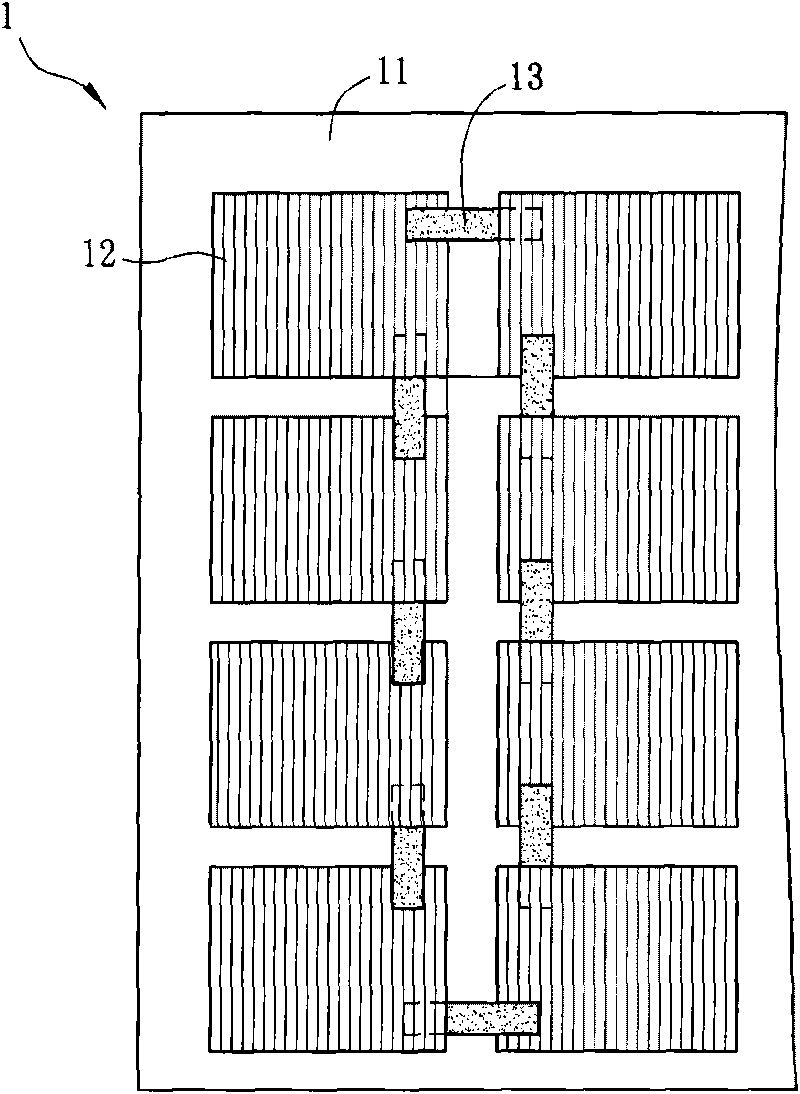

A solar cell and electrode technology, applied in photovoltaic modules, circuits, photovoltaic power generation, etc., can solve the problems of poor process efficiency of solar cell module 1, poor reliability of solar cell module 1, and defects of solar cell module 1, etc. The effect of improving reliability, avoiding cost, and reducing light-receiving area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

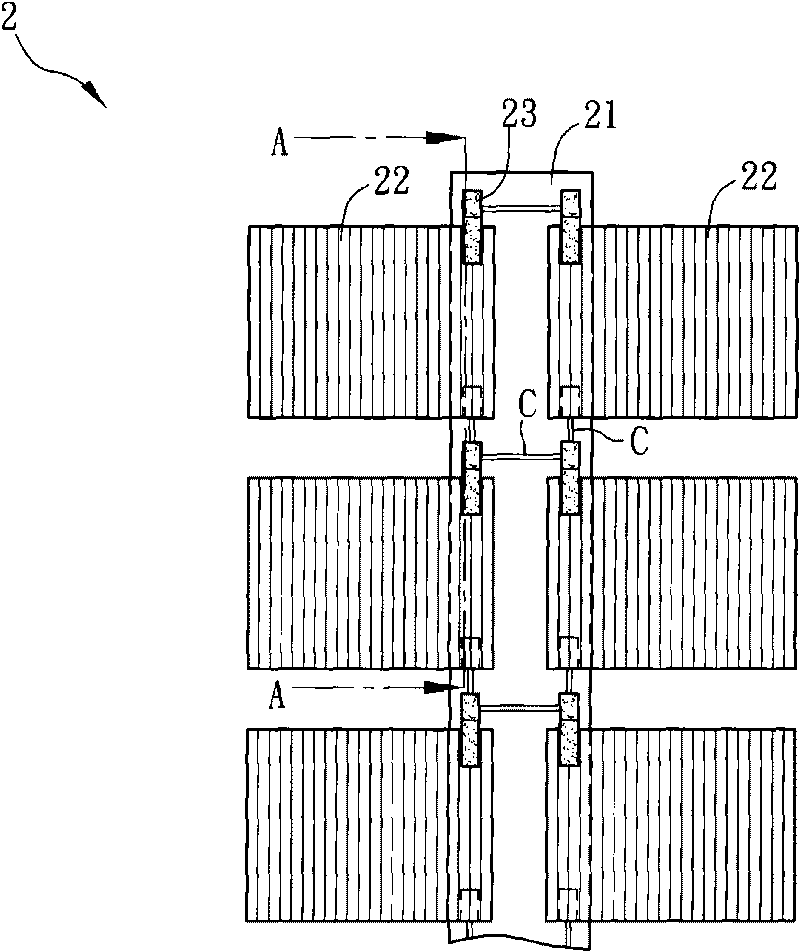

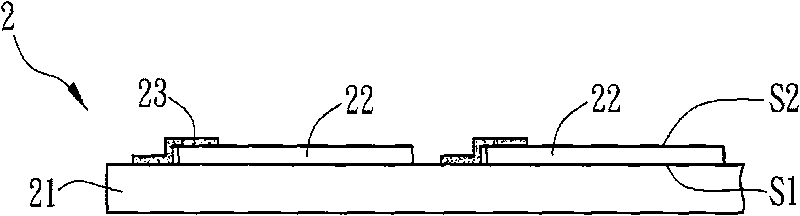

[0018] Figure 2A It is a schematic diagram of a solar cell module 2 in a preferred embodiment of the present invention, Figure 2B for the solar module 2 along Figure 2A The cross-sectional schematic diagram of the line A-A in the middle. The solar cell module 2 includes a circuit board 21 and a plurality of solar cell elements 22 .

[0019] The material of the circuit board 21 can be, for example, glass or sapphire or quartz or plastic.

[0020] The solar cell element 22 can also be called a photovoltaic cell device, and its type can be, for example, a thin film solar cell device, a mono-crystalline silicon solar cell device, Polycrystalline silicon solar cell device (poly-crystalline silicon solar cell device), or organic solar cell device (organic solar cell device). Wherein, the organic solar cell device may be, for example, a dye-sensitized solar cell device.

[0021] The solar cell element 22 is connected to the circuit board 21 , partly fixed on the circuit board...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com