Cable connector using insulation-piercing mode to connect cables

A cable connector and cable connection technology, which is applied in the direction of needle point/slotted plate contact pieces and cable joints used to penetrate insulated wires/cable core wires, and can solve the problem of insufficient torque nut connection pressure, continuous increase in temperature rise, Shell thermal deformation and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

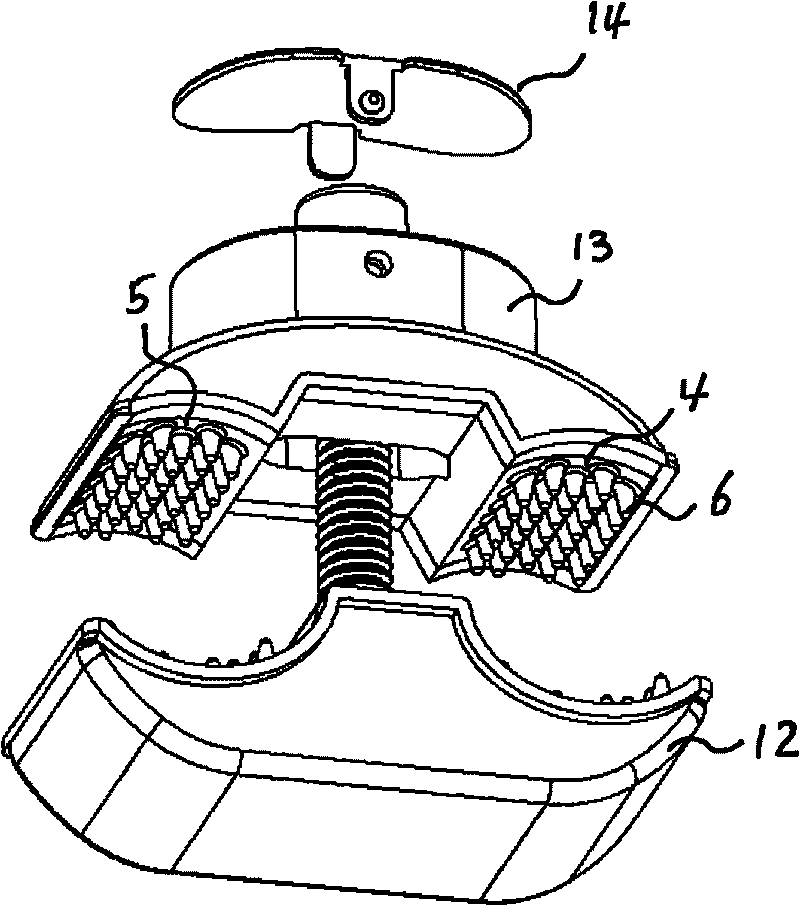

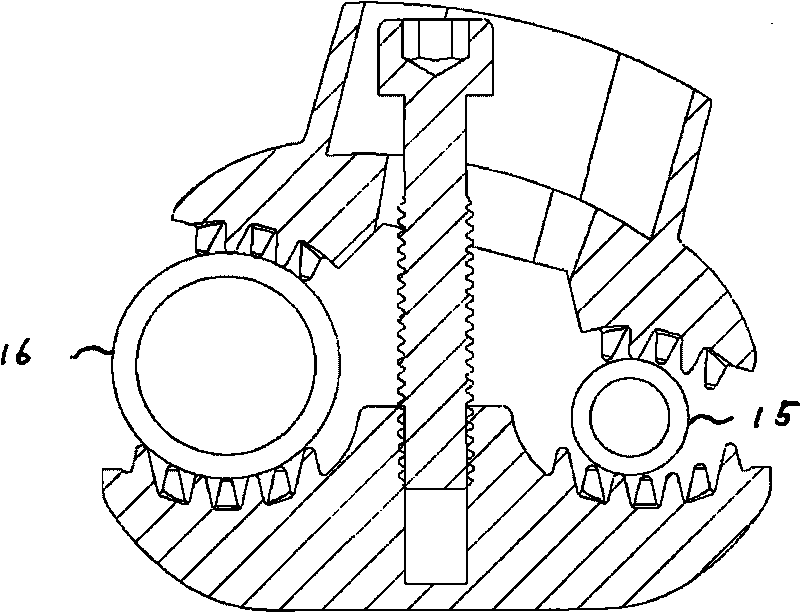

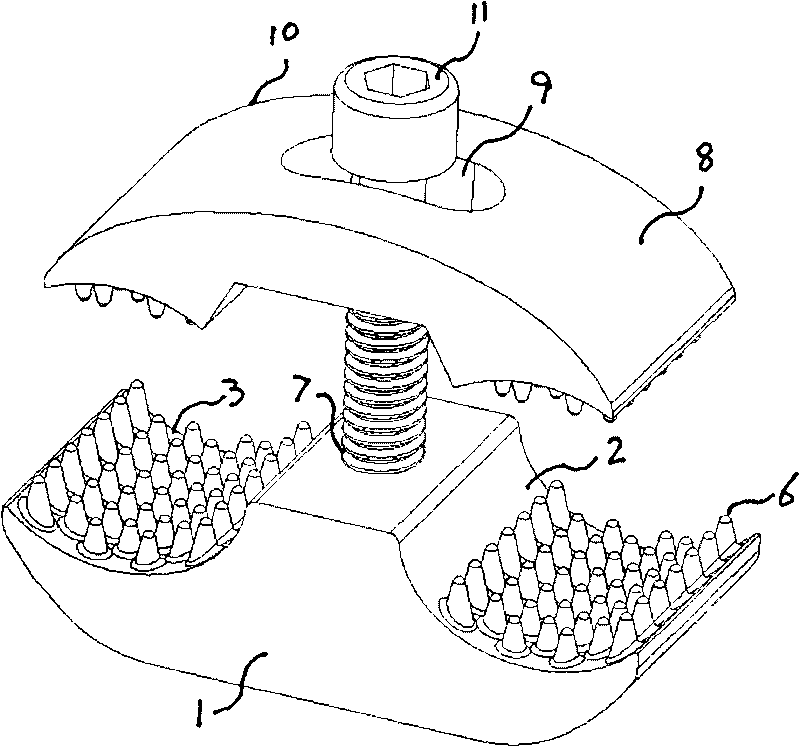

[0014] See Figure 1-3 Clamping inner arc surfaces 2 and 3 are arranged on the main connecting body 1, clamping needles 6 are arranged on the clamping inner arc surface, vertical thread mounting holes 7 are arranged on the main connecting body, and clamping inner arc surfaces 4 and 5 are arranged on the clamping body 8 , the clamping needle 6 is set on the inner arc surface of the clamping body, the fan-shaped mounting hole 9 on the clamping body, the outer arc surface 10, the connecting bolt 11, the main connector body is coated with an insulating layer 12, the clamping body is coated with an insulating layer 13, and the protective cover 14 is installed. Cable section 15, 16.

[0015] When in use, the cables 15 and 16 with insulation are placed in the clamping inner arc surfaces 2, 3, 4 and 5 of the main connecting body 1 and the clamping body 8, and the connecting bolts 11 are gradually tightened, and the clamping needle 6 penetrates When the insulation layer of the cable i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com