Brushless synchronous dynamo

A synchronous motor and rotor technology, which is applied in the direction of controlling generators through magnetic field changes, can solve the problems of high shaft vibration and tile amplitude, complex system structure, long shaft system of the unit, etc., to achieve convenient adjustment and control, and simple system structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

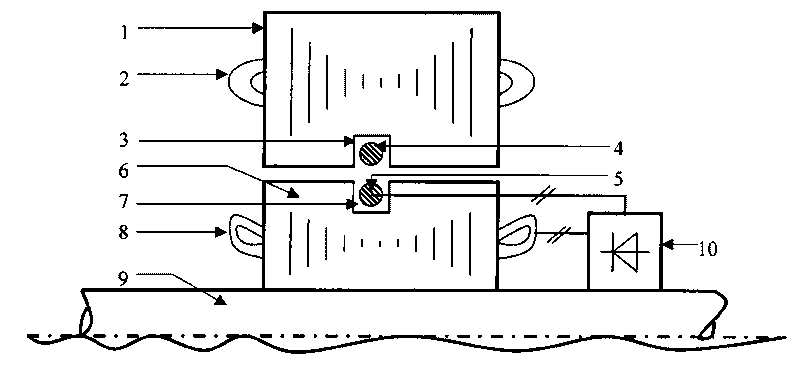

[0018] Embodiment 1: The brushless synchronous motor, in figure 1 Among them, it consists of a stator, a rotor, a rotating shaft 9 and a rotary rectifier 10. The stator is composed of stator core 1, stator three-phase power winding 2 and stator single-phase excitation winding 4, and the rotor is composed of rotor AC induction winding 5, rotor core 6 and rotor DC winding 8.

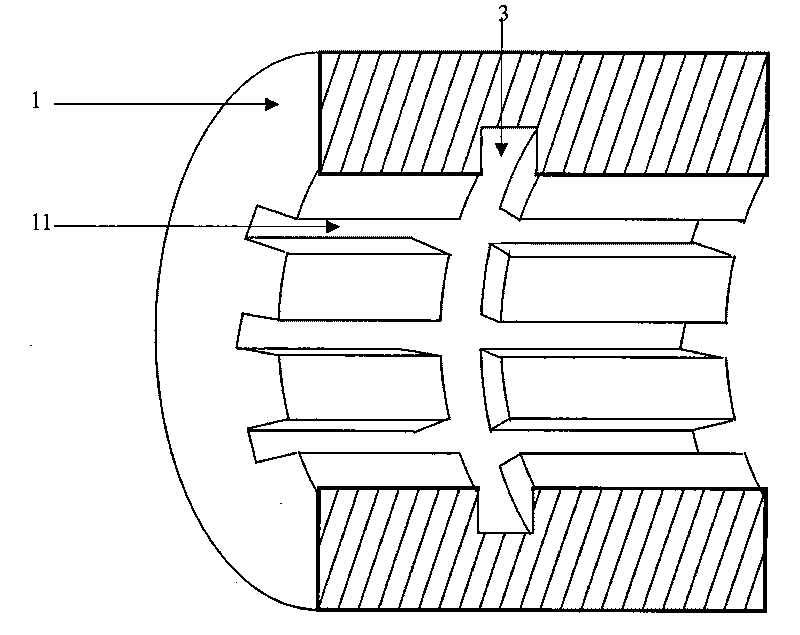

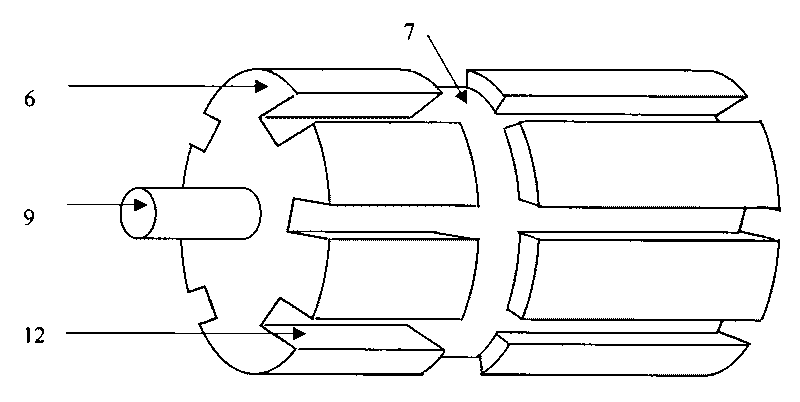

[0019] Both the stator core 1 and the rotor core 6 are made of silicon steel sheets with a thickness of 0.3 mm. There are multiple stator three-phase power winding slots 11 and one stator single-phase excitation winding slot 3 on the inner surface of the stator core, and multiple rotor DC winding slots 12 and one rotor AC induction winding slot 7 on the outer surface of the rotor core. .

[0020] exist figure 2 Among them, the inner surface of the stator core 1 has two kinds of stator slots: the stator three-phase power winding slot 11 and the stator single-phase excitation winding slot 3, the stator t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com