Insulating quilt of sunlight green house

A technology of solar greenhouse and thermal insulation quilt, applied in greenhouse cultivation, synthetic resin layered products, gardening, etc., can solve the problems of heavy thermal insulation quilt, non-waterproof thermal insulation quilt, poor thermal insulation effect, etc. Outstanding thermal insulation effect and good thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

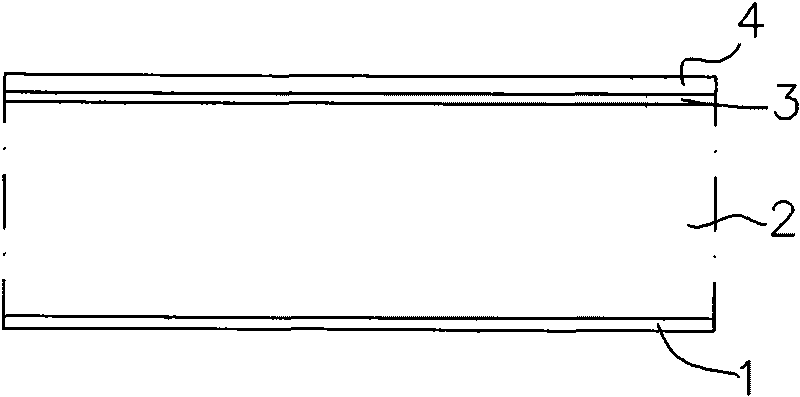

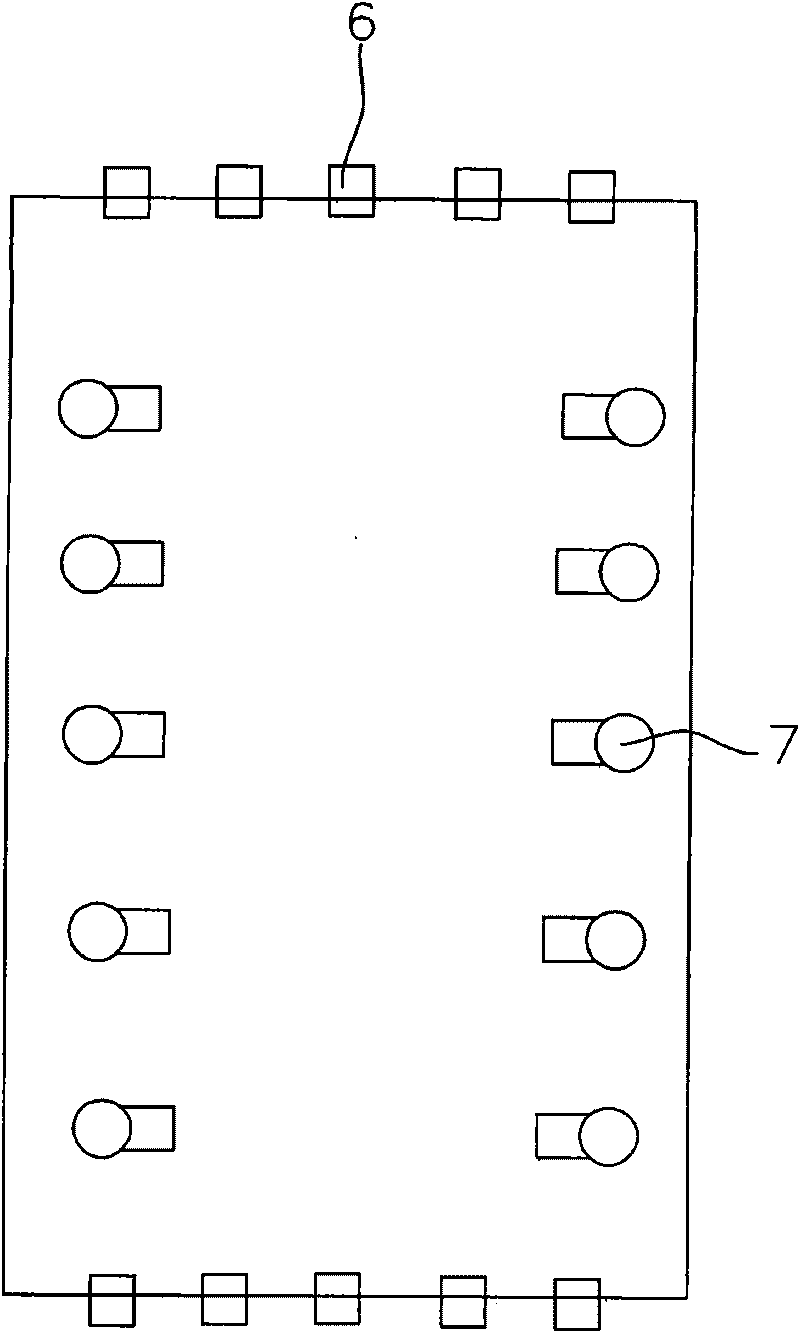

[0021] Such as Figure 1-2 As shown, a thermal insulation quilt for a solar greenhouse, the key point of which is that the chemical fiber spray-bonded cotton 2 with a weight of 250-600 grams per square meter is used as the main body of the thermal insulation quilt, and the chemical fiber spray-bonded cotton 2 is made of polyester, acrylic, or One or several types of nylon are used as raw materials. In order to reduce costs, chemical fiber spray-bonded cotton 2 is made of leftovers from textile or garment factories after blooming, carding, and polyester staple fibers. The quality of the leftovers and polyester staple fibers is The ratio is 75 parts: 25 parts, using the glued cotton technology to make glued cotton with a width of 2-3 meters, the lower surface of the chemical fiber glued cotton 2 is sewn with the lower chemical fiber cloth 1 by a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com