Method for sorting batteries by sucker-type electromagnets

An electromagnet and sucker-type technology, which is applied in the field of battery sorting by using a sucker-type electromagnet, can solve problems such as low sorting efficiency, misoperation, and expensive equipment, achieve high sorting speed, avoid misclassification, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

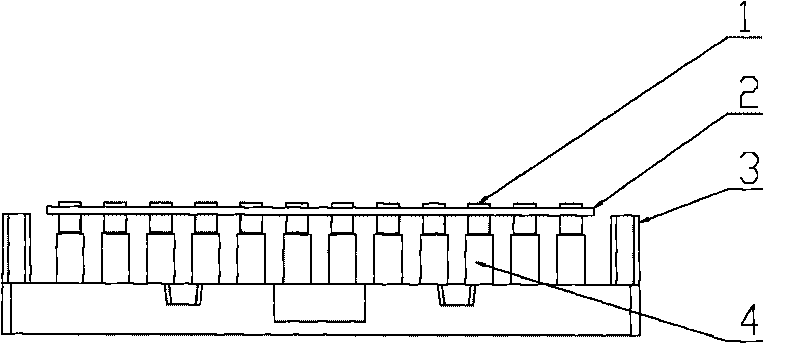

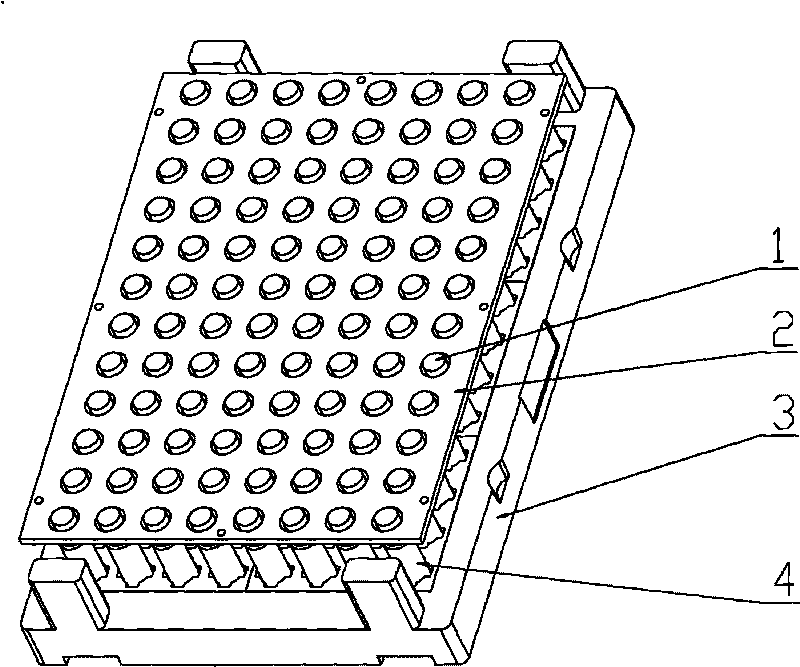

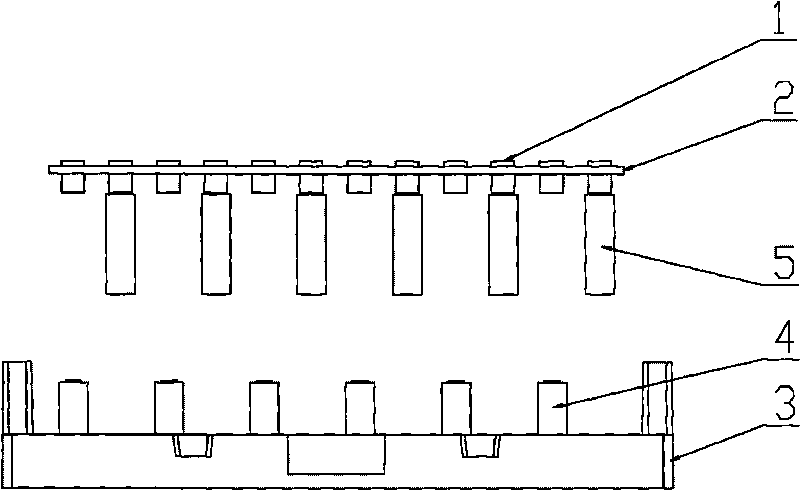

[0013] There are 96 battery holes (6) on the battery turnover tray (3). The assembled batteries are installed in the middle of the battery holes of the battery turnover tray in turn, and then put into the battery formation testing equipment for formation and testing. The system computer root battery formation testing The batteries in the battery turnover tray are divided into several categories according to the data and specific classification methods, and the computer transmits the classification information of the batteries to the sorting machine. The sorting machine has a mounting plate (2) for installing a suction cup electromagnet on the top of the battery turnover tray (3), and there is a suction cup electromagnet (1) above each pre-sorted battery (4), and the suction cup electromagnet receives The computer instruction and the relay control keep the power-on or power-off state respectively, and the magnetic field generated by the energized suction cup type electromagnet f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com