Oil film static-pressure guide device

A static pressure guide rail and oil film technology, which is applied in the direction of large fixed members, metal processing machinery parts, metal processing equipment, etc., can solve the problems of wasting lubricating oil, easily damaged guide rails, and uneven distribution, so as to achieve uniform distribution of hydraulic oil and use Long service life and uniform distribution of oil film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

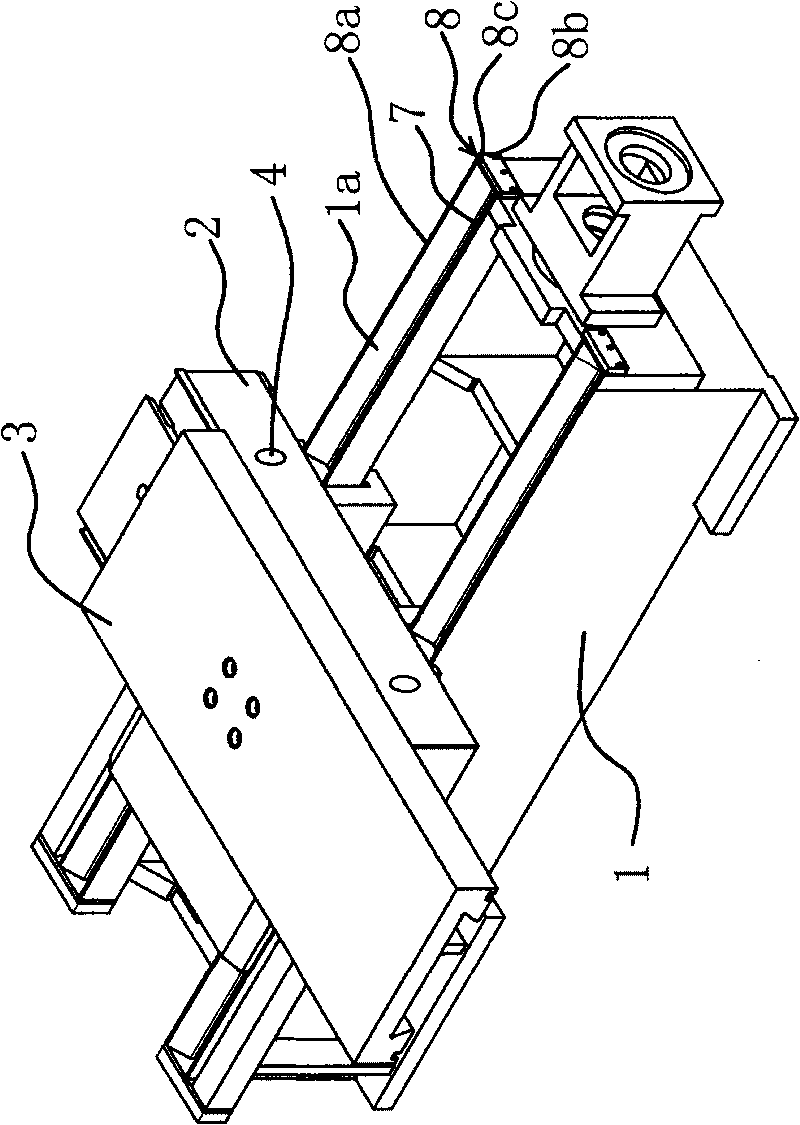

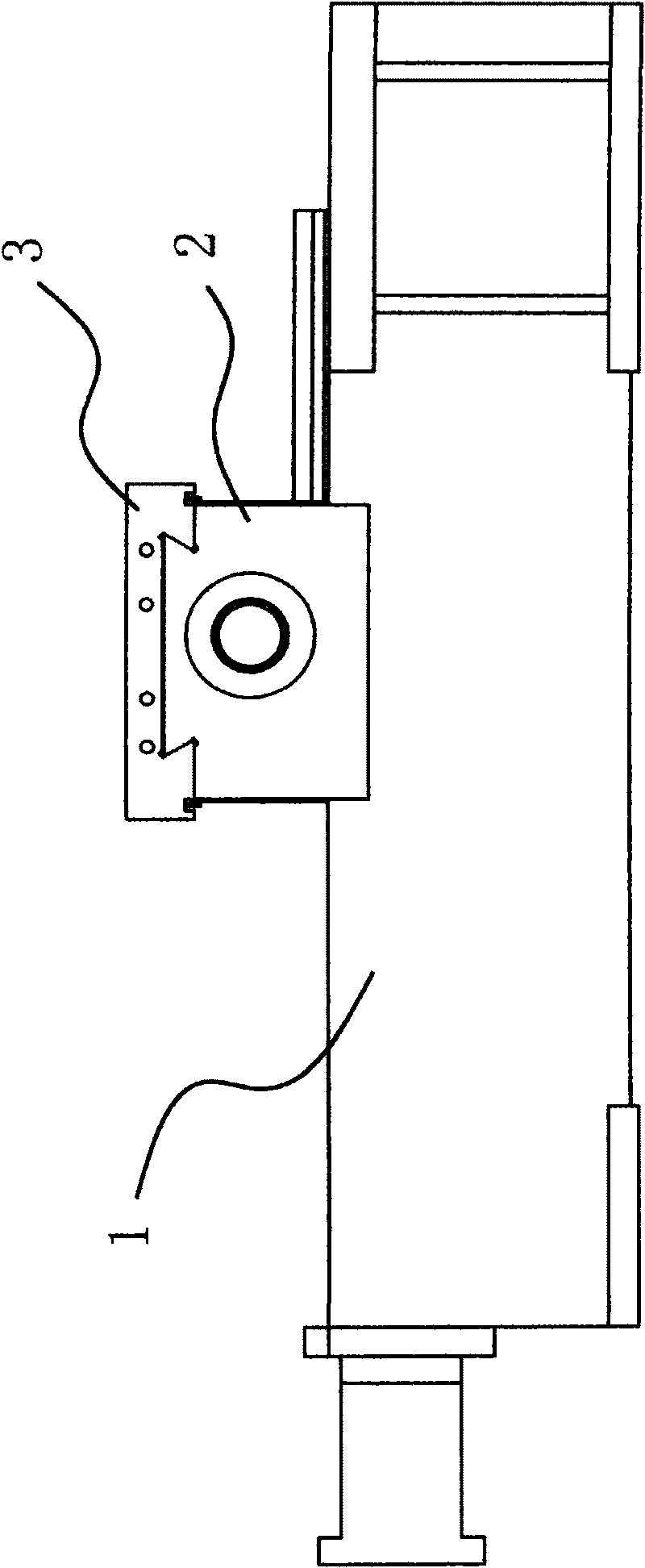

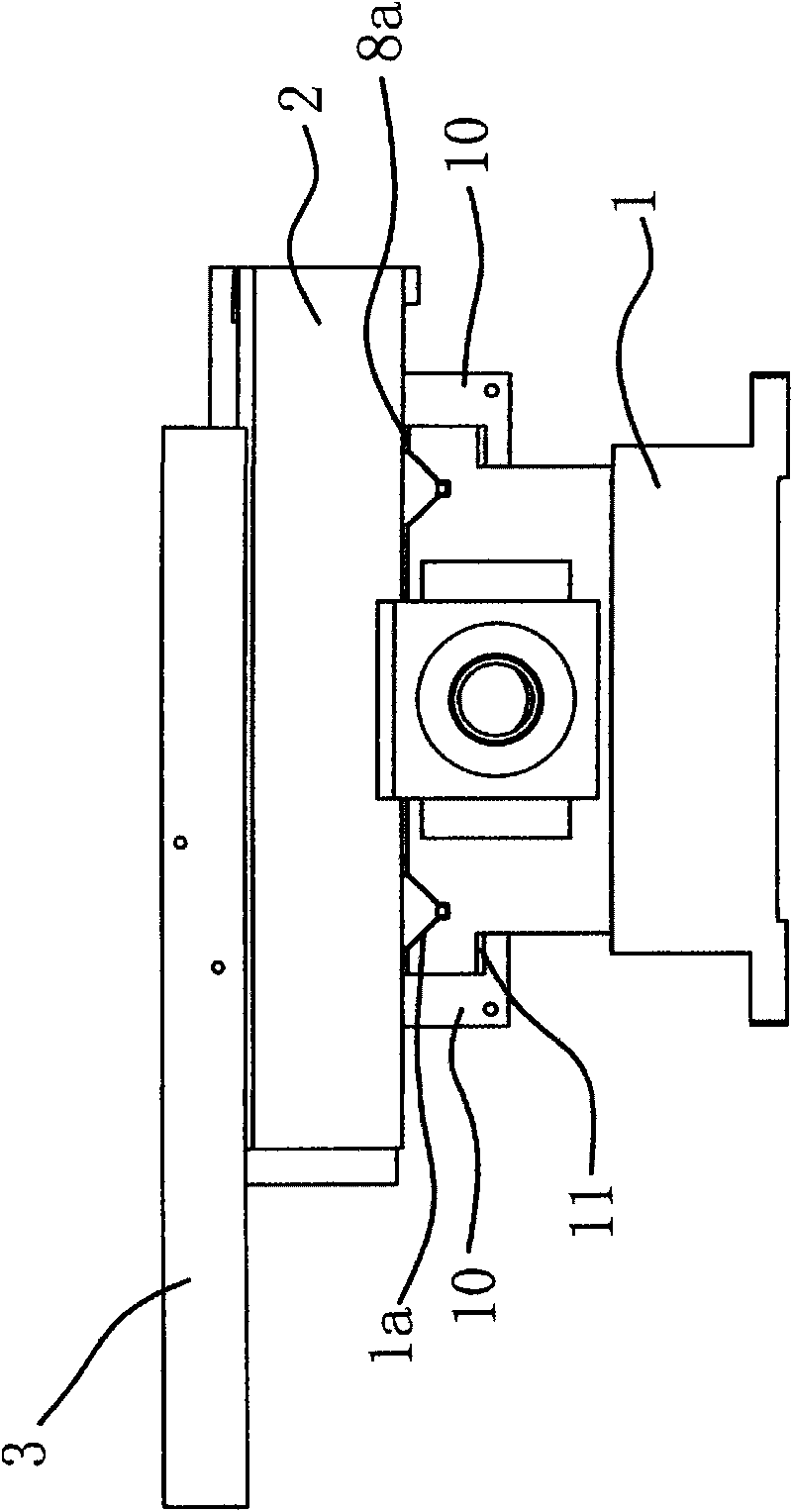

[0035] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the oil film static pressure guide rail device is composed of a guide rail frame 1, a large carriage 2 and a small carriage 3, etc.

[0036] Specifically, the guide rail frame 1 is provided with a longitudinal guide rail 1a, and the guide rail 1a is a concave guide groove in a V row. The large carriage 2 is arranged on the guide rail 1a and has a shape that matches the guide rail 1a. The large carriage 2 The movement in the longitudinal horizontal direction is realized on the guide rail 1a. The small carriage 3 is set on the large carriage 2. The top of the large carriage 2 has a horizontal dovetail-shaped bump, and the bottom of the small carriage 3 has a dovetail groove matching the dovetail-shaped protrusion. The small carriage 3 is set on the large carriage. on the carriage 2 to realize the movement in the horizontal direction.

[0037] A hydraulic pump is placed outside the guide rail frame 1. Acc...

Embodiment 2

[0044] Such as Figure 7 As shown, the principle and structure of this embodiment are basically the same as those of Embodiment 1, the difference is that the grooves 9 in this embodiment are in the shape of vertical and horizontal intersections, and the oil hole 6 is located at the intersection of the grooves 9 . In this way, the hydraulic oil enters the groove 9 from the oil hole 6, and the groove 9 is filled with hydraulic oil so that the hydraulic oil is evenly and fully distributed between the large carriage 2 and the guide rail 1a, which ensures the uniformity of the oil film and ensures that the belt The stability and precision of the operation of the oil film hydrostatic guide rail device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com