Potato starch degradation plastic product

A technology of potato starch and degrading plastics, applied in the field of plastic products, can solve problems such as refractory degradation and non-environmental protection, and achieve the effect of easy purchase and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

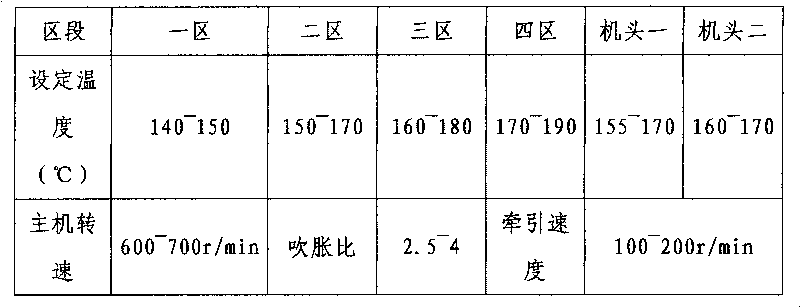

Examples

no. 1 Embodiment

[0009] The first specific embodiment of the present invention, a packaging bag produced by using biological potato starch degradation masterbatch as raw material, consists of the following components according to the weight ratio: biological potato starch degradation masterbatch---20%, metallocene- --5%, biodegradation accelerator 3%, photosensitizer---1%, PE wax---5%, LLDPE---50%, HDPE---16%.

no. 2 Embodiment

[0010] In the second specific embodiment of the present invention, a packaging bag produced using biological potato starch degradation masterbatch as raw material is composed of the following components according to the weight ratio: biological potato starch degradation masterbatch---30%, metallocene- --10%, biodegradation accelerator---1.5%, photosensitizer---0.5%, PE wax---1%, LLDPE---40%, HDPE---17%.

no. 3 Embodiment

[0011] In the third specific embodiment of the present invention, a mulch film produced using biological potato starch degradation masterbatch as raw material is composed of the following components according to the weight ratio: biological potato starch degradation masterbatch --- 40%, metallocene --- -5%, biodegradation accelerator---1%, photosensitizer---1%, PE wax---3%, LLDPE---30%, HDPE---20%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com