Absorption refrigerator by adopting CO2 as refrigerant

An absorption refrigerator and refrigerant technology, applied in the field of refrigerators in the field of refrigeration, can solve the problems of low efficiency, complex and large structure, etc., and achieve good application prospects, environmental friendliness, and compact structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

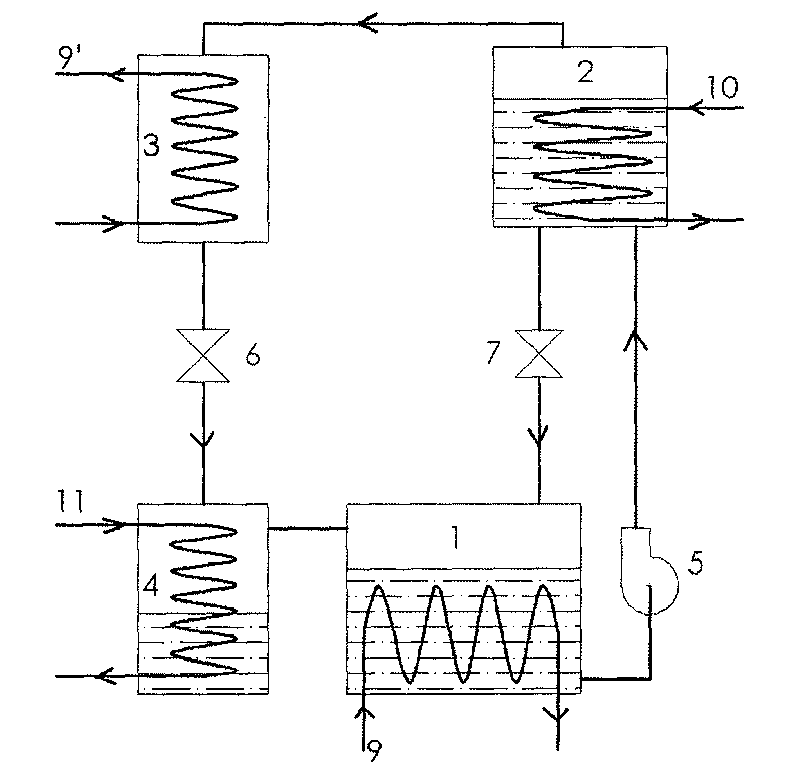

[0026] figure 2 For the use of CO in the present invention 2 Be the structural representation of the embodiment 1 of the absorption refrigerating machine of refrigerant; As can be seen from the figure, the present invention adopts CO 2 Absorption chillers as refrigerants mainly include:

[0027] The absorber 1, the flow control valve 7, the generator 2, the condenser 3, the restrictor 6 and the evaporator 4 which are connected in sequence and form a refrigeration circuit, and the absorber 1 and the generator 2 which are connected Connect the liquid pump 5 on the pipeline, the inlet of the liquid pump 5 is connected with the absorber 1, and the outlet of the liquid pump 5 is connected with the generator 2; a flowing working medium circulates in the refrigeration circuit;

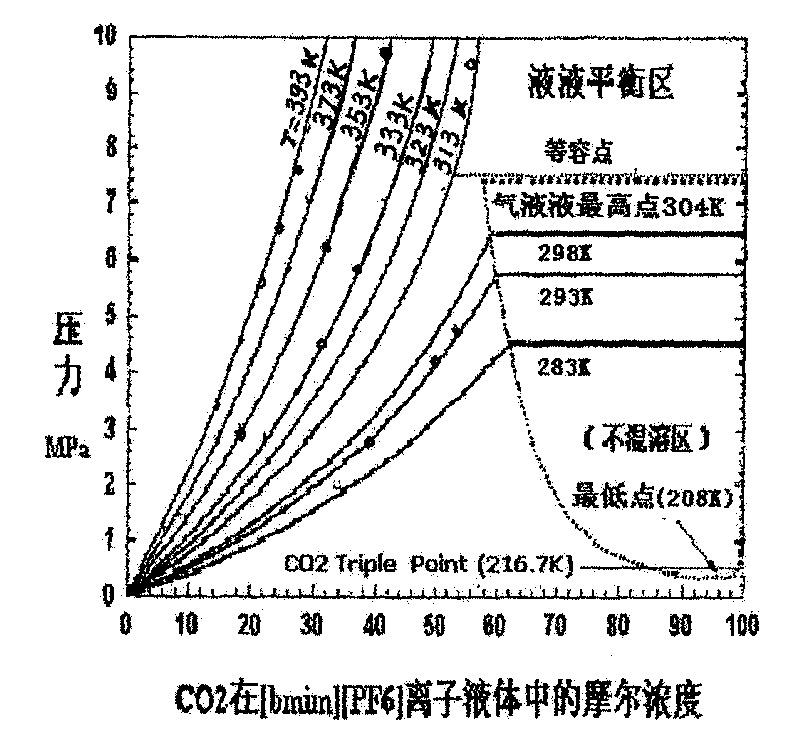

[0028] The flowing working medium includes absorbent and refrigerant; the refrigerant is CO 2 ; The absorbent is an ionic liquid, an alkaline solution or a mixed solution of the two.

[0029] The flowing...

Embodiment 2

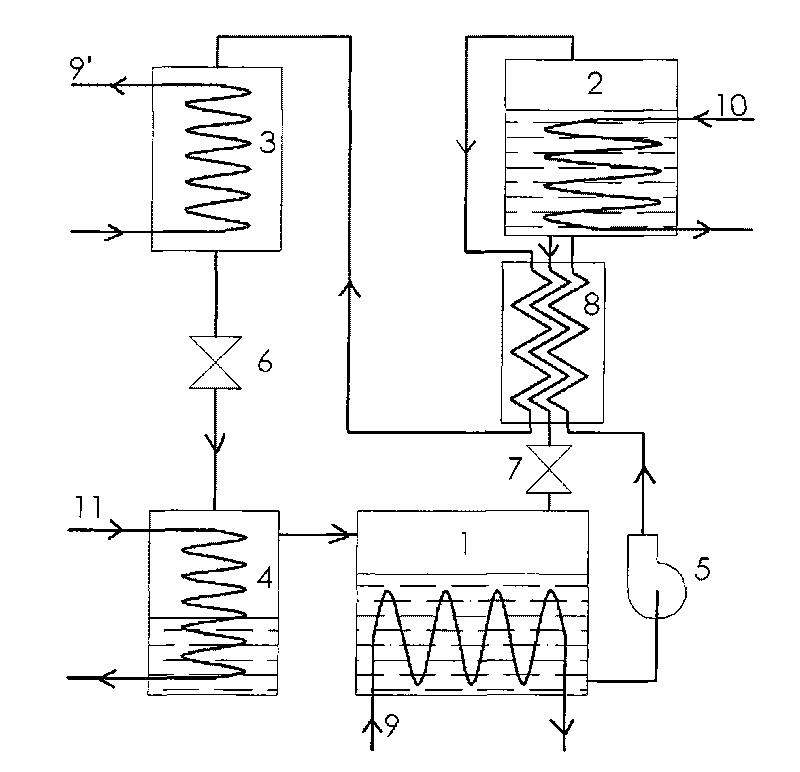

[0031] image 3 For the present invention using CO 2 It is a structural schematic diagram of embodiment 2 of an absorption refrigerator for refrigerant; as can be seen from the figure, embodiment 2 is different from embodiment 1 by adding a regenerator 8, and its connection relationship is as follows image 3 As indicated by the arrows in , the refrigerant used is CO 2 , the absorbent ionic liquid is [EMIm]NTf 2 ; Absorber 1 contains CO at about 15°C 2 and [EMIm]NTf 2 The dilute solution is pressurized by the liquid pump 5 (the pressure is increased from 3MPa to 9MPa), heated by the counterflow regenerator 8, and enters the generator 2; the mixed solution in the generator 2 is heated by the heater 10, and the temperature rises to 400°C, due to temperature rise, CO 2 In [EMIm] NTf 2 Solubility decreases in CO, part of the CO 2 Separation from the mixed solution and become supercritical CO 2 High-pressure gas, CO2 gas exchanges heat with the dilute solution from the pump...

Embodiment 3

[0033] Figure 4 For the use of CO in the present invention 2 It is the structural representation of the embodiment 3 of the absorption refrigerating machine of refrigerant; As can be seen from the figure, the structure of embodiment 3 is basically the same as that of embodiment 2; because CO 2 The critical point temperature of the evaporator 4 is relatively low, if it is allowed to throttle and refrigerate at room temperature, it is difficult to produce a good cooling effect, so in this embodiment, the temperature and pressure from the evaporator 4 are still relatively low CO 2 The gas flows through the condenser 3, so that the high-pressure CO 2 The gas is cooled to below room temperature and then throttled and expanded, so that the CO 2 achieve better cooling effect. In this example, the refrigerant is CO 2 , the absorbent is alkaline solution N-methyldiethanolamine (CH3-N(CH 2 CH2OH) 2 ) solution; N-methyldiethanolamine (MDEA) and CO 2 The reaction generates unstabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com