Lead chamber and control integrative detection device

A detection device and lead room technology, applied in nuclear engineering, protected chambers, material analysis using radiation, etc., can solve the problems of increasing the size of the lead room, long installation time, low work efficiency, etc., to improve the degree of automation , Outline size reduction, saving time and labor for installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

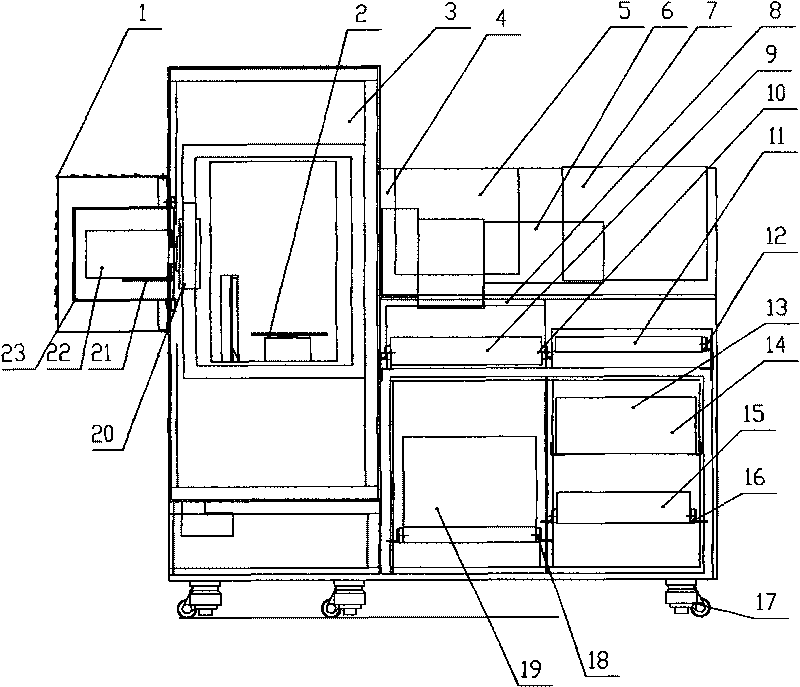

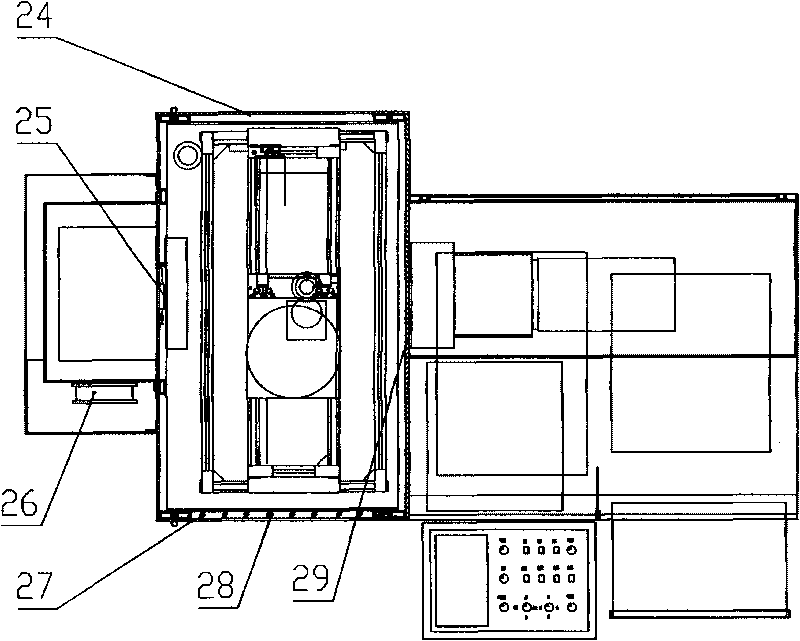

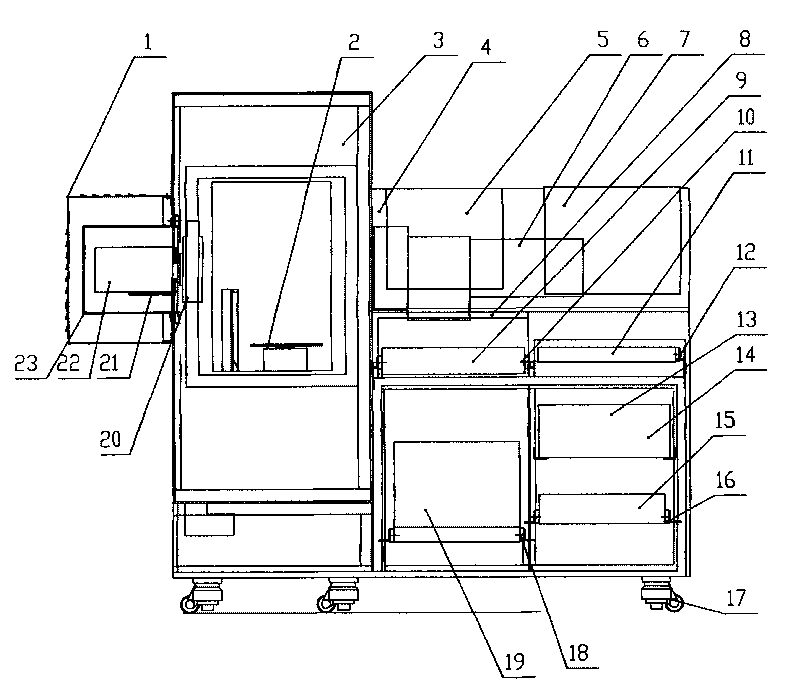

[0008] The structure of the present invention will be described in detail in conjunction with the accompanying drawings.

[0009] A lead room and control integrated detection device, such as figure 1 and figure 2 As shown, the detection platform 2 installed in the lead room can move forward and backward, left and right, up and down, and rotate in four axes. The detection platform 2 is connected by aluminum profiles, which is simple to install, beautiful in appearance and stable in movement. The distance between the X-ray generator 22 and the image intensifier 6 is set according to the detection distance 600mm specified by the detection standard. The left and right movement of the detection platform 2 can adjust the focal length, and adjust the clarity of the received image and the size of the field of view. Due to the limited field of view of the image intensifier, the design of the four axes of movement directions, front and rear, left and right, lifting and rotating, can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com