Ceramic chip assembly and manufacturing method thereof

A chip and ceramic technology, applied in the field of ceramic chip components, can solve the problems of reduced adhesive strength, difficulty in providing ceramic chip components, and difficulty in protecting ceramic chips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

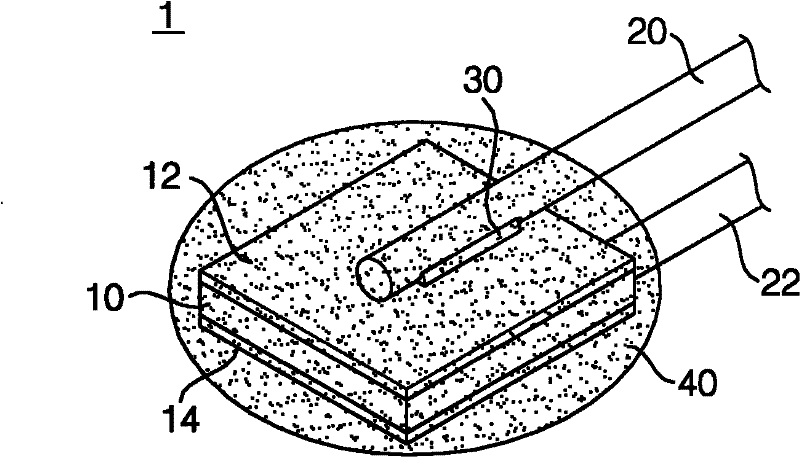

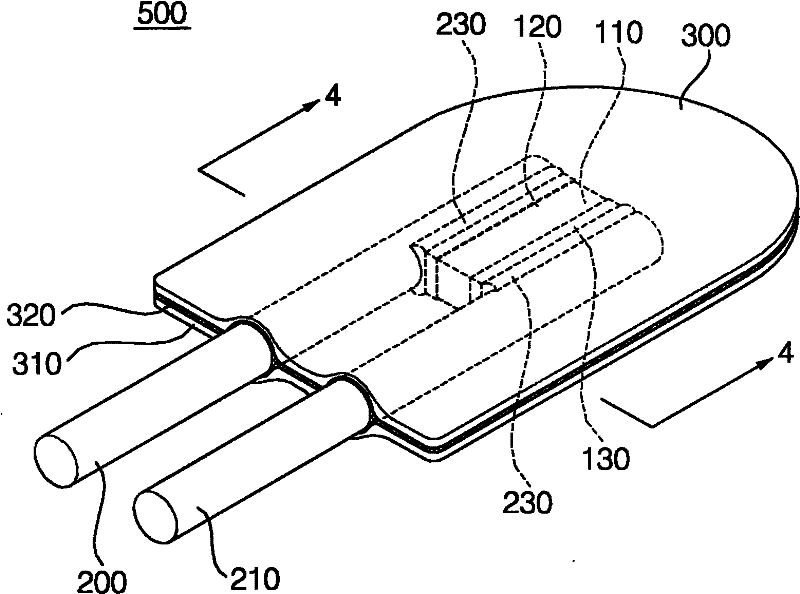

[0055] Now, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

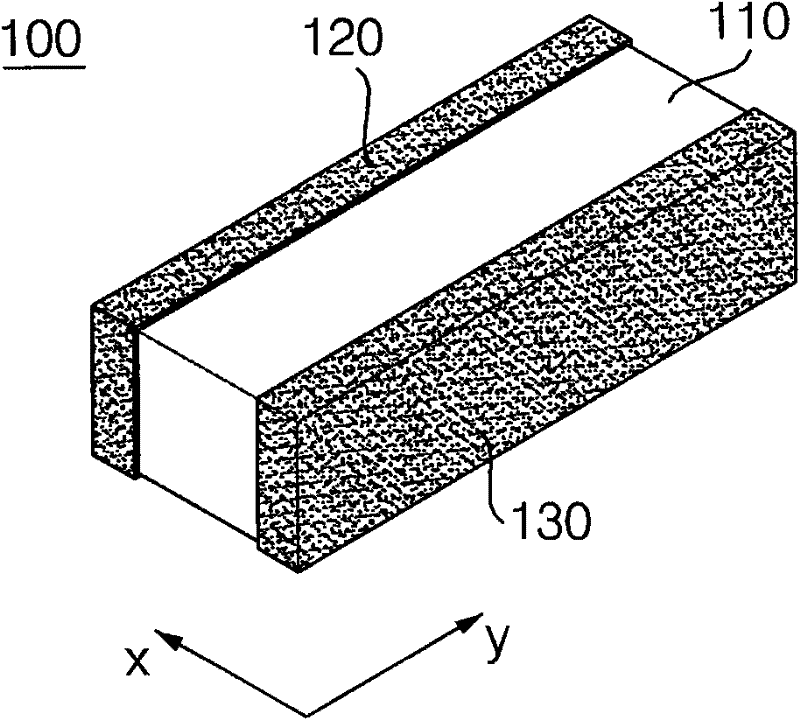

[0056] figure 2 is a view showing an exemplary ceramic chip 100 applied to a ceramic chip assembly according to an embodiment.

[0057] refer to figure 2 , the ceramic chip 100 includes a ceramic base 110 and external electrodes 120 , 130 .

[0058] The ceramic base 110 has a hexahedral shape and electrical properties. External electrodes 120 and 130 are oppositely formed on both side surfaces of the ceramic base 110 .

[0059] According to an embodiment, the length, thickness, and width of the ceramic chip 100 may be about 1 mm, about 0.30 mm, and about 0.5 mm, respectively, but are not limited thereto.

[0060] If the size of the ceramic chip 100 is too small, automation of tape and reel may encounter difficulty when manufacturing a ceramic chip assembly.

[0061] The external electrodes 120 and 130 may be formed at both ends of the cer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com